Method for preparing graphene by using lignin

A technology of lignin and graphene, applied in graphene, chemical instruments and methods, non-metallic elements, etc., can solve the problems of low quality of graphene products, no graphene, long reaction period, etc., and achieve high value The effect of chemical utilization, abundant raw materials and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

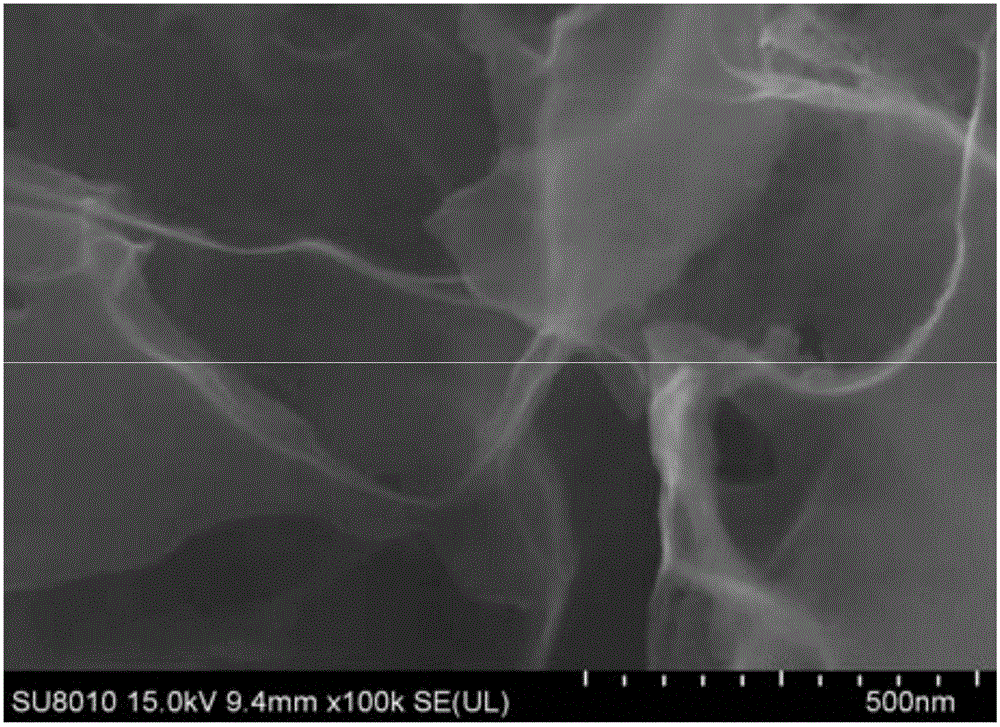

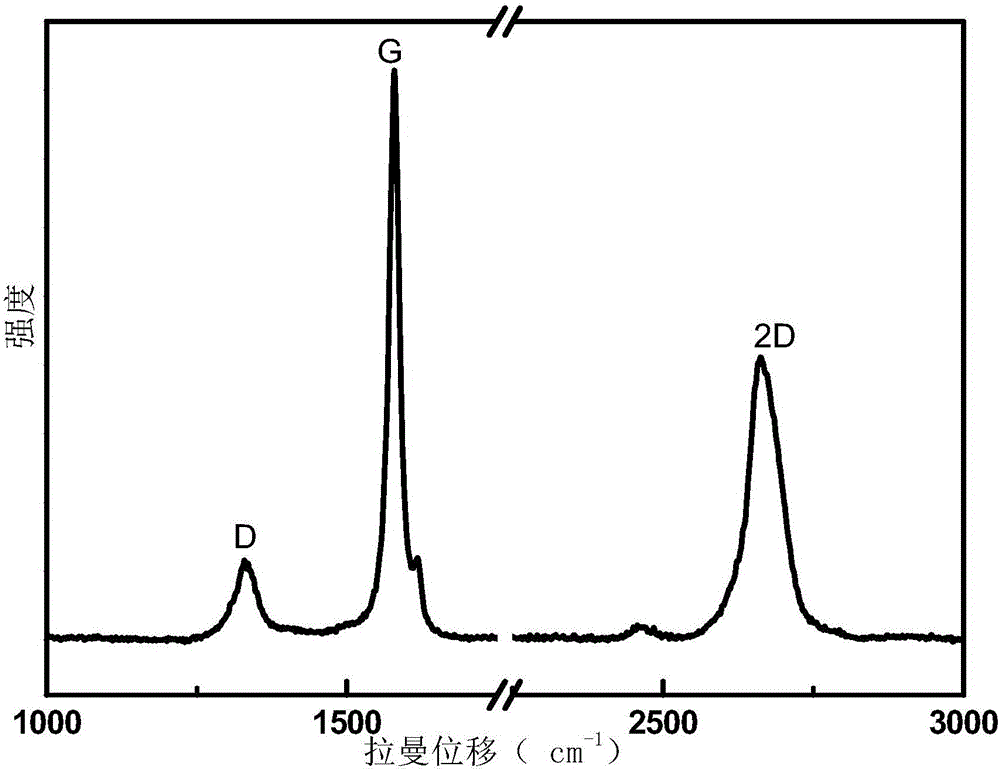

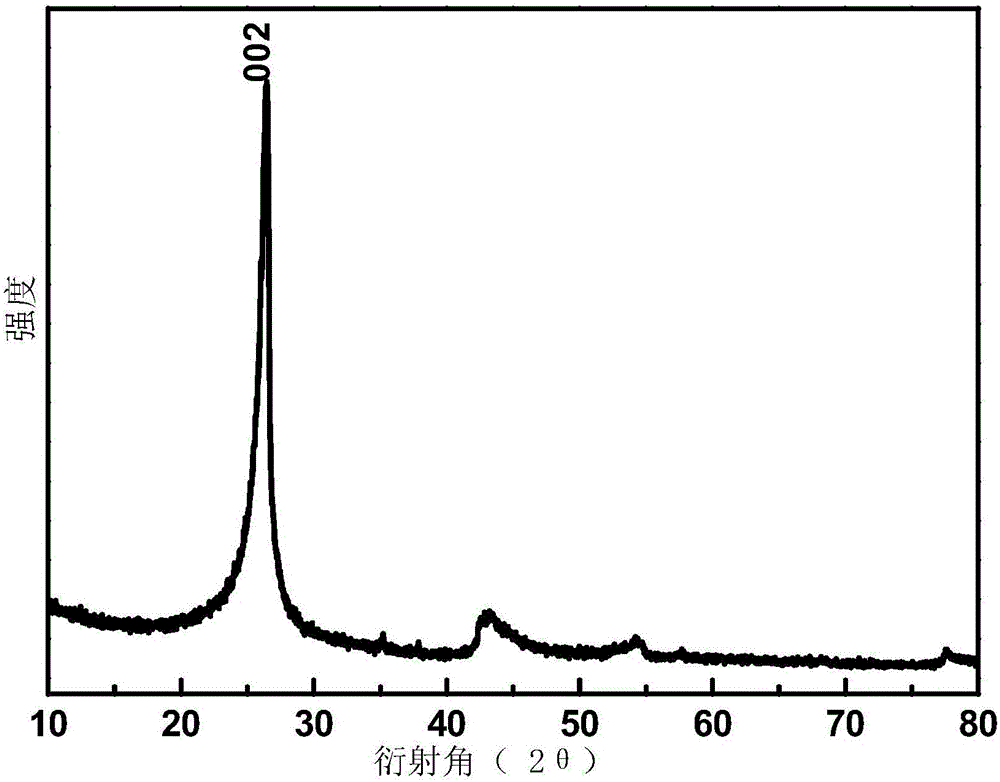

Method used

Image

Examples

Embodiment 1

[0032] (1) Make sodium lignosulfonate (sodium lignosulfonate, hereinafter referred to as SL) SL into a 1g / L aqueous solution, and weigh 20.20gFe(NO 3 ) 3 9H 2 O solid, dissolved in water to form a 0.1mol / L solution.

[0033] (2) Fully immerse the pretreated quartz glass slide in SL solution for 10 minutes, soak it in ultrapure water for 5 minutes after taking it out, then rinse it with ultrapure water several times, and dry it with cold wind; then put it into ferric nitrate solution Immerse in water for 10 minutes, take it out, soak it in ultrapure water for 5 minutes, rinse it several times, and dry it with cold wind; you can get a layer of SL / Fe 3+ Electrostatic self-assembled film; repeat the above operations to obtain 10 layers of SL / Fe 3+ Electrostatic self-assembled films.

[0034] (3) Place the sample obtained in step (2) in a tube furnace with two temperature zones, and feed H at a rate of 70mL / min. 2 / Ar (5:95, V / V) mixed gas is used as protective gas and reducing...

Embodiment 2

[0039] (1) Make SL into a 2g / L aqueous solution, weighing 26.28g NiSO 4 ·6H 2 O solid, dissolved in water to form a 0.2mol / L solution.

[0040] (2) Fully immerse the pretreated quartz glass slide in SL solution for 10 minutes, soak it in ultrapure water for 5 minutes after taking it out, then rinse it with ultrapure water several times, and dry it with cold wind; then put it into nickel sulfate solution Immerse in water for 10 minutes, take it out, soak it in ultrapure water for 5 minutes, rinse it several times, and dry it with cold wind; you can get a layer of SL / Ni 2+ Electrostatic self-assembled film; repeat the above operations to obtain 10 layers of SL / Ni 2+ Electrostatic self-assembled films.

[0041] (3) Place the sample obtained in step (2) in a tube furnace with two temperature zones, and feed H at a rate of 20mL / min. 2 / Ar (5:95, V / V) mixed gas was used as protective gas and reducing gas, and the temperature was programmed at a rate of 8°C / min at the same time. ...

Embodiment 3

[0044] (1) Make SL into a 4g / L aqueous solution, weighing 12.48gCuSO 4 ·5H 2 O solid, dissolved in water to form a 0.1mol / L solution.

[0045] (2) Fully immerse the pretreated copper sheet in the SL solution for 10 minutes, soak it in ultrapure water for 5 minutes after taking it out, then rinse it with ultrapure water several times, and dry it with cold wind; then put it into the copper sulfate solution Immerse for 10 minutes, take it out, soak it in ultrapure water for 5 minutes, rinse it several times, and dry it with cold wind; you can get a layer of SL / Cu 2+ Electrostatic self-assembled film; repeat the above operations to obtain 10 layers of SL / Cu 2+ Electrostatic self-assembled films.

[0046] (3) Place the sample obtained in step (2) in a tube furnace with two temperature zones, and feed H at a rate of 100mL / min. 2 / Ar (5:95, V / V) mixed gas was used as protective gas and reducing gas, and the temperature was programmed at a rate of 8°C / min at the same time. The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com