Self-assembling growth method of layer-controllable colloidal crystal

A technology of colloidal crystals and growth methods, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of complex preparation methods, difficult control, and difficulty in obtaining colloidal crystals with a controllable number of layers, and achieve simple process , easy to control, overcome the effect that the number of layers is not easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

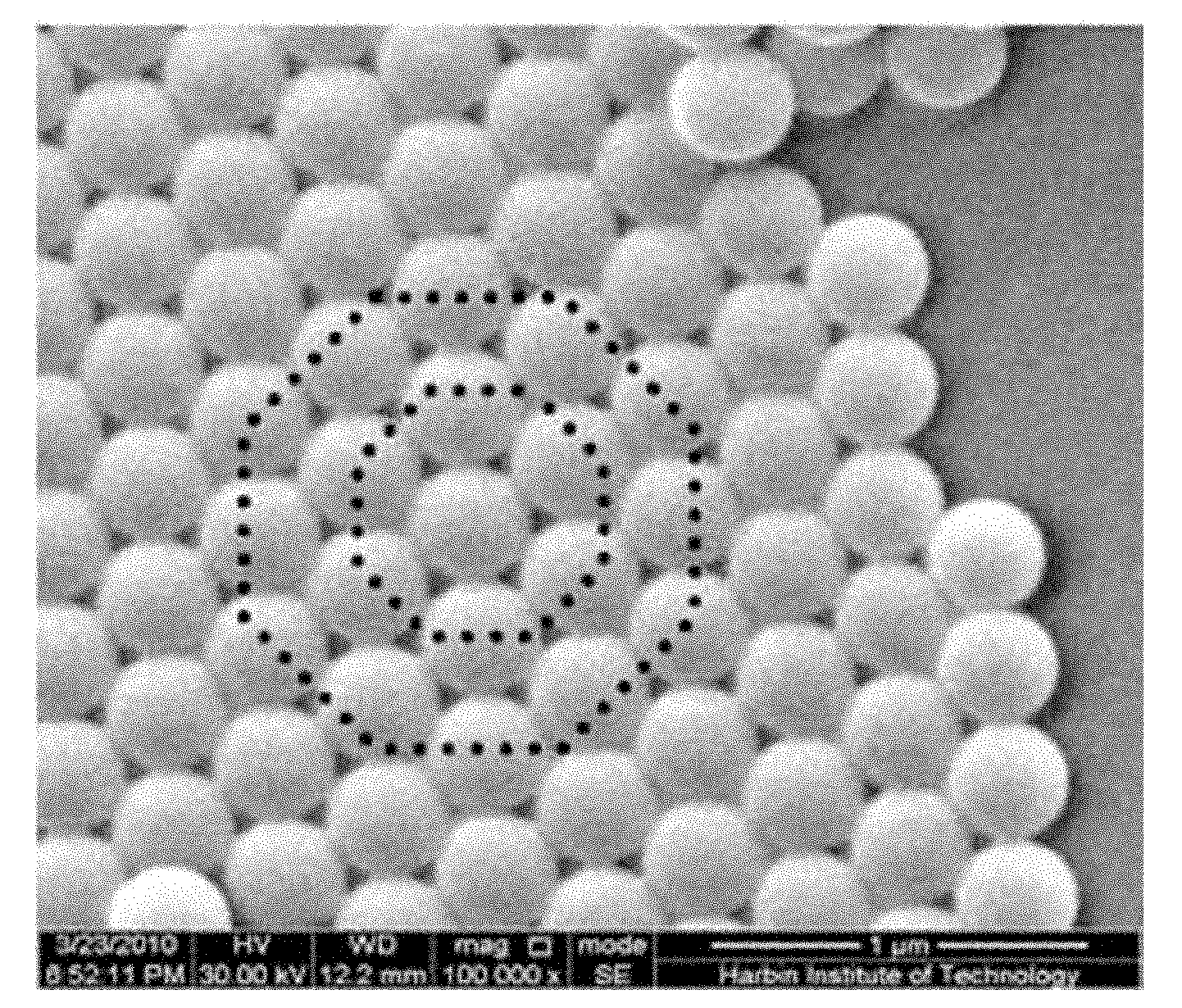

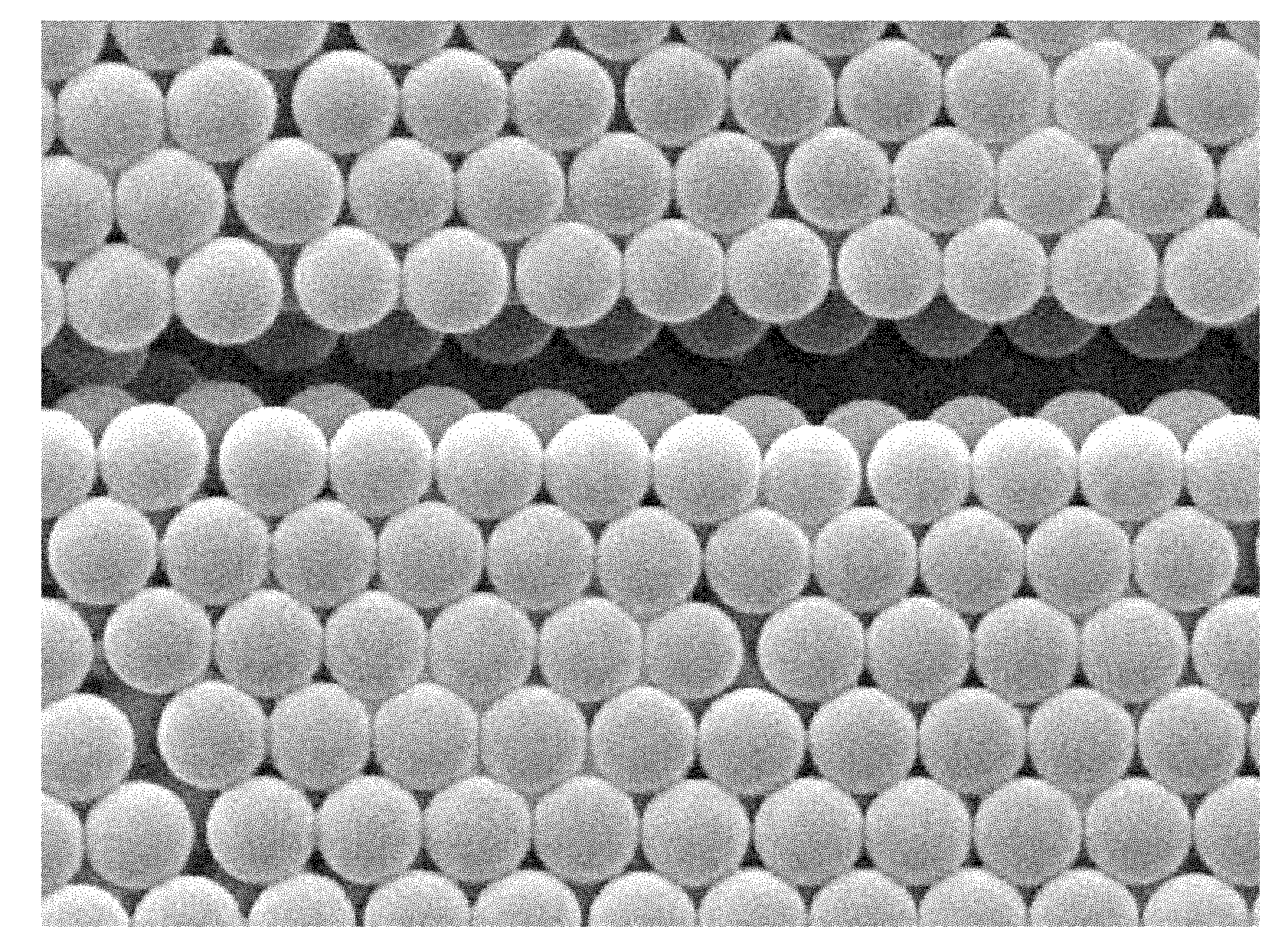

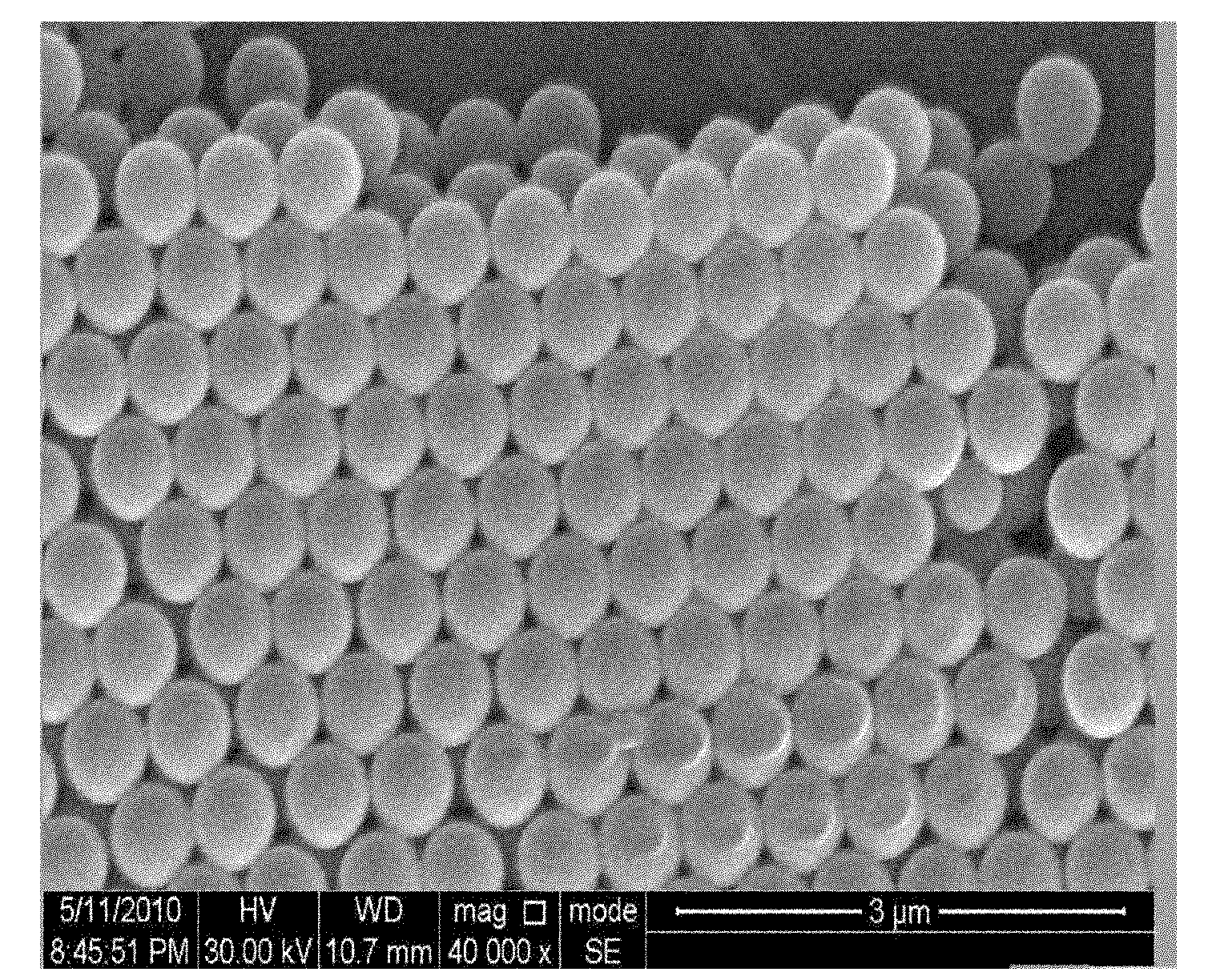

[0012] Embodiment 1: This embodiment is a self-assembly growth method of colloidal crystals with a controllable layer number. The self-assembly growth method of colloidal crystals with a controllable layer number is realized through the following steps: 1. Put the substrate in acetone, methanol and Ultrasonic cleaning in ultra-pure water for 20-30 minutes, then treating with ozone for 30-60 minutes, and then drying; 2. Put the colloidal particles and dispersion solvent into a flat-bottomed test tube to prepare a colloidal particle suspension with a mass fraction of 0.005% to 2%. , wherein the dispersion solvent is one or a mixture of ultrapure water and absolute ethanol; 3. Insert the substrate treated in step 1 into the colloidal particle suspension at an angle of 60°-80° to the bottom of the flat-bottomed test tube immerse the substrate completely in the colloidal particle suspension, and then place the flat-bottomed test tube in a constant temperature incubator with a temper...

specific Embodiment approach 2

[0016] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the substrate in step 1 is an ordinary glass substrate, ITO conductive glass sheet, quartz glass sheet or silicon wafer. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the colloidal particles described in step two are monodisperse silicon dioxide (SiO 2 ), polystyrene (PS) or polymethyl methacrylate (PMMA) microspheres, or one of the above colloidal particles coated with gold, silver, copper, platinum or TiO 2 formed nanoparticles. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0018] In this embodiment, the particle size of the colloidal particles is 100-1000 nm, and the standard deviation of the particle size of the colloidal particles is less than 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com