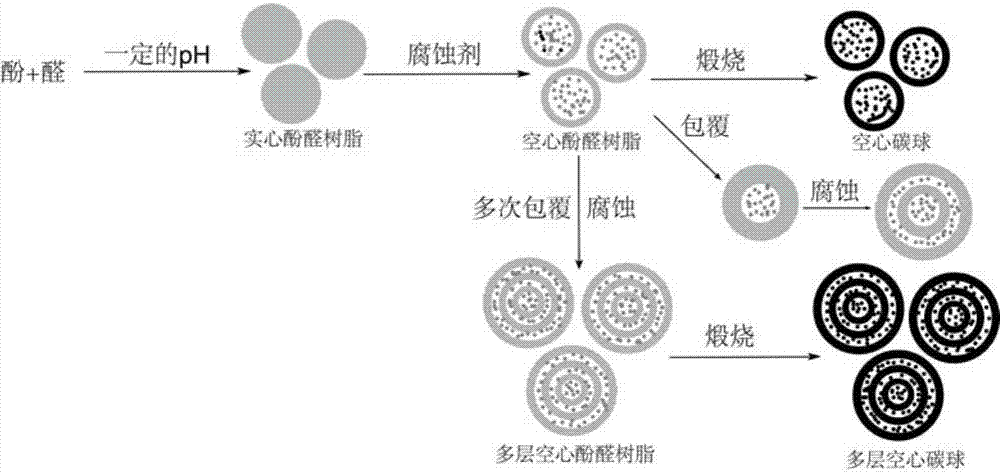

Single-layer and multi-layer hollow carbon nanosphere and preparation method and application thereof

A hollow carbon sphere, single-layer technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of cumbersome steps in the template method, and achieve the effect of mild reaction conditions and simple operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0128] Embodiment A1, using method A to prepare hollow carbon spheres:

[0129] Weigh 0.1g 3-aminophenol and dissolve in 20ml H 2 O and 10ml EtOH mixed solution, add ammonia and formaldehyde solution and stir at room temperature for 1.3h.

[0130] Add 20ml of acetone to the reaction vessel, continue to stir at room temperature for 30min, centrifuge the precipitate, and wash it twice with ethanol. The obtained precipitate is fully dried in a drying oven at 80°C for 4h to obtain the intermediate product II.

[0131] The dried intermediate product II was placed in a tube furnace with a hydrogen-argon gas mixture (5 / 95% by volume), raised from room temperature to 900°C at a heating rate of 5°C / min, and calcined at 900°C After 10 hours, it was naturally cooled to room temperature to obtain a single-layer hollow carbon sphere II with a clean interior.

[0132] Finally, a single-layer hollow carbon sphere with mesoporous distribution inside is obtained, with an outer diameter of 30...

Embodiment A2

[0134] Example A2, using method A to prepare a carbon sphere structure with overall mesoporous distribution:

[0135] The difference with embodiment A1 is:

[0136] Weigh 0.1g 3-aminophenol in 16ml H 2 O and 14ml EtOH mixed solution, add ammonia and formaldehyde solution and stir at room temperature for 45min.

[0137] Finally, a carbon sphere structure with mesoporous distribution throughout is obtained, and the diameter of the sphere is 280-360 nm.

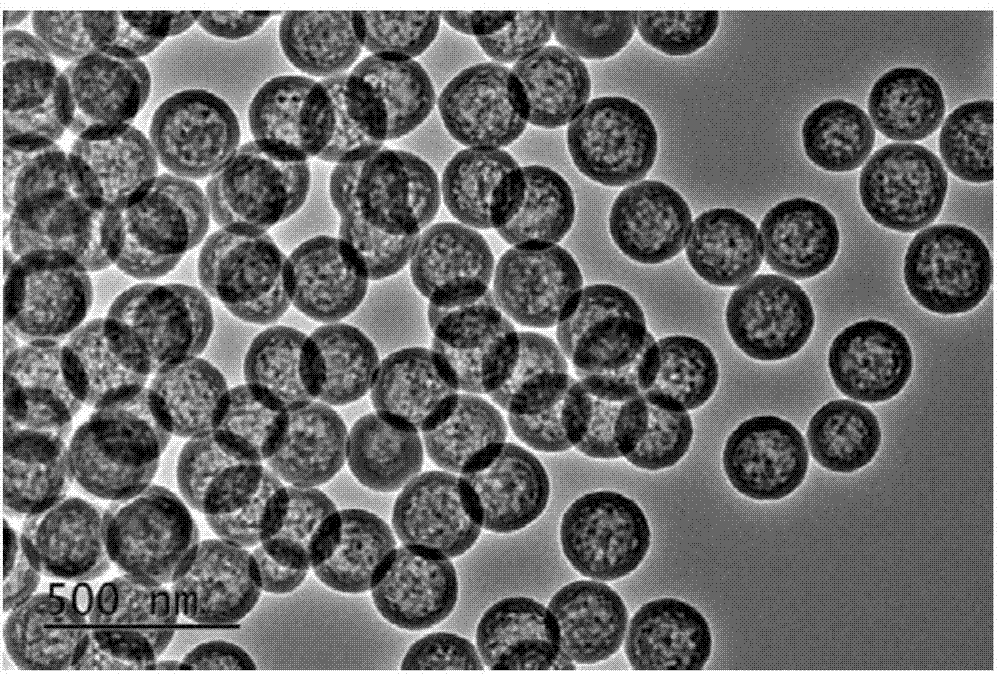

[0138] image 3 It is a transmission electron microscope (TEM) image of the carbon sphere structure with overall distribution of mesoporous cells prepared in this example. It can be seen from the figure that the scale of the hollow carbon sphere is 300-350 nm.

Embodiment A3

[0139] Embodiment A3, using method A to prepare the yolk-shell hollow structure with solid carbon spheres inside:

[0140] The difference with embodiment A1 is:

[0141] Weigh 0.4g 3-aminophenol in 20ml H 2 O and 10ml EtOH mixed solution, add 0.1ml ammonia and 0.4ml formaldehyde solution and stir at room temperature for 1.3h.

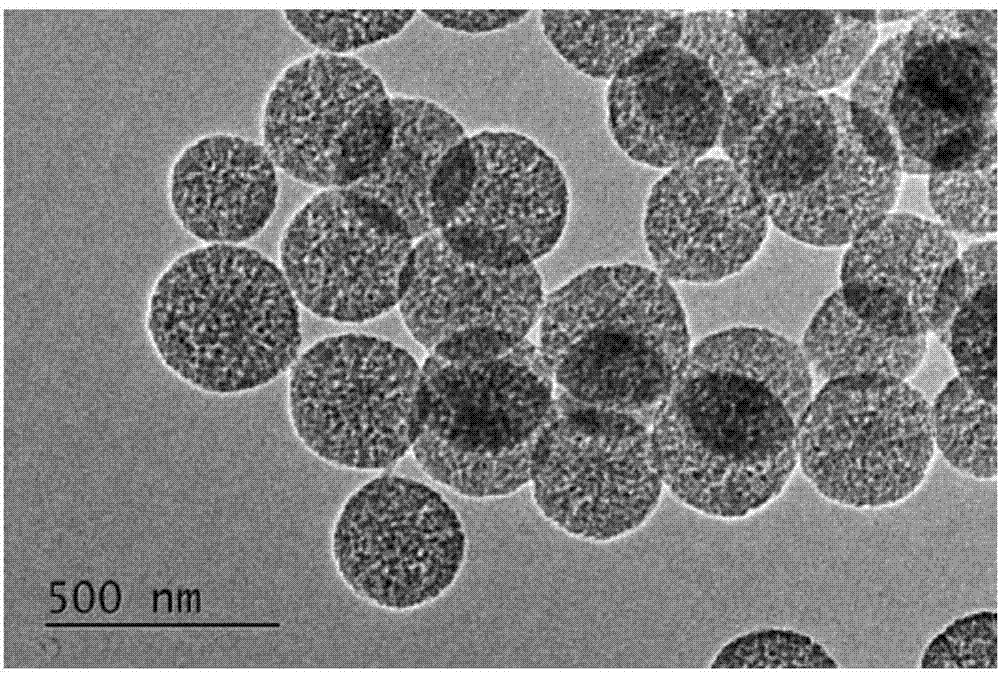

[0142] The end result is a hollow yolk-shell structure with solid carbon spheres inside. The outer diameter of the obtained hollow carbon sphere structure is 470-520nm, and the diameter of the inner solid sphere is 200-250nm.

[0143] Figure 4 The transmission electron microscope (TEM) figure of the hollow yolk-shell carbon sphere material prepared by the present embodiment is equipped with solid carbon spheres inside, as can be seen from the figure that the outer diameter of the sphere is about 500nm, and the diameter of the inner solid sphere is about 230nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com