Method for preparing high-quality graphene with controllable layer number

A high-quality, graphene technology, applied in the field of macro-production of high-quality graphene with a controllable number of layers, can solve problems such as restricting physical property research and further application, many graphene defects, and difficult to control the number of layers, and achieves low cost. , good dispersion, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The artificial graphite powder of size<10 μ m is raw material, and graphite powder average particle size is 8 μ m in the present embodiment; Adopt Hummer method [" Hummer method " please refer to literature: Hummers W, Offman R.Journal of The American Chemical Society 1958,80: 1339 .] Oxidation for 10 hours; rapid heating to the expansion temperature of 1100°C at a heating rate of 50°C / s, rapid expansion in an atmosphere of argon (flow rate 200ml / min), and a residence time of 10s; at 450°C, hydrogen (100ml / min) ) + argon (100 liters / min) in a reducing atmosphere for 2 hours; ultrasonically dispersed in NMP for 2 hours at 40°C, with an ultrasonic dispersion power of 300W; 20,000 rpm high-speed centrifugation was used to remove graphite and Thick graphite flakes.

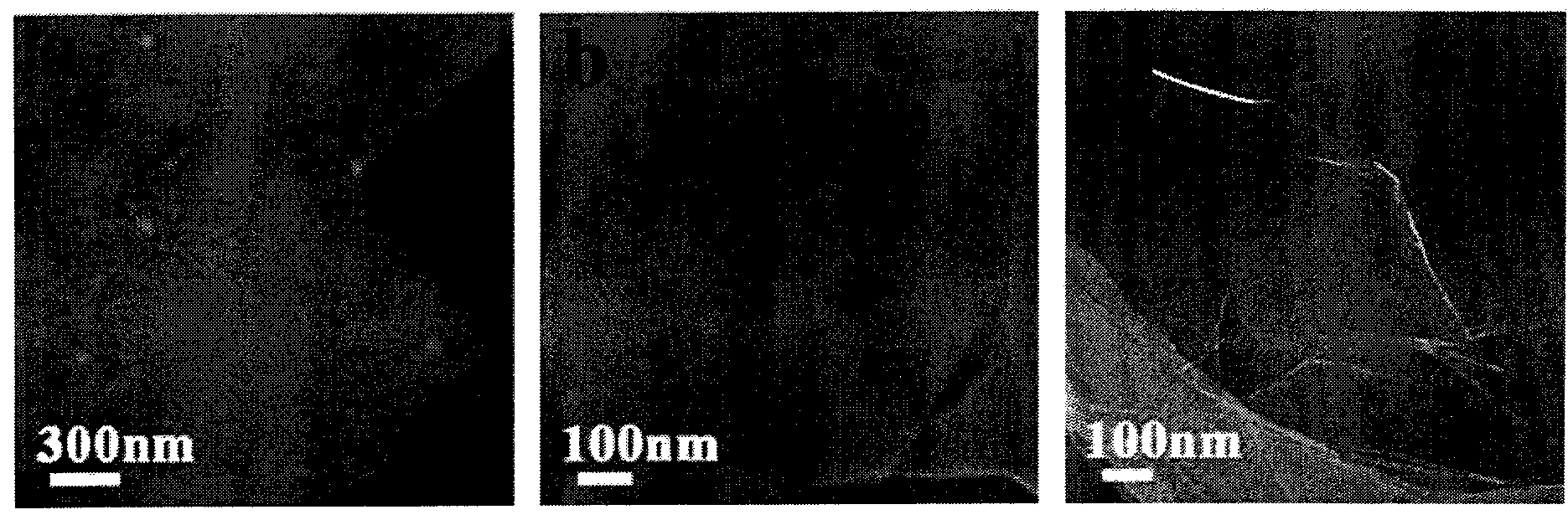

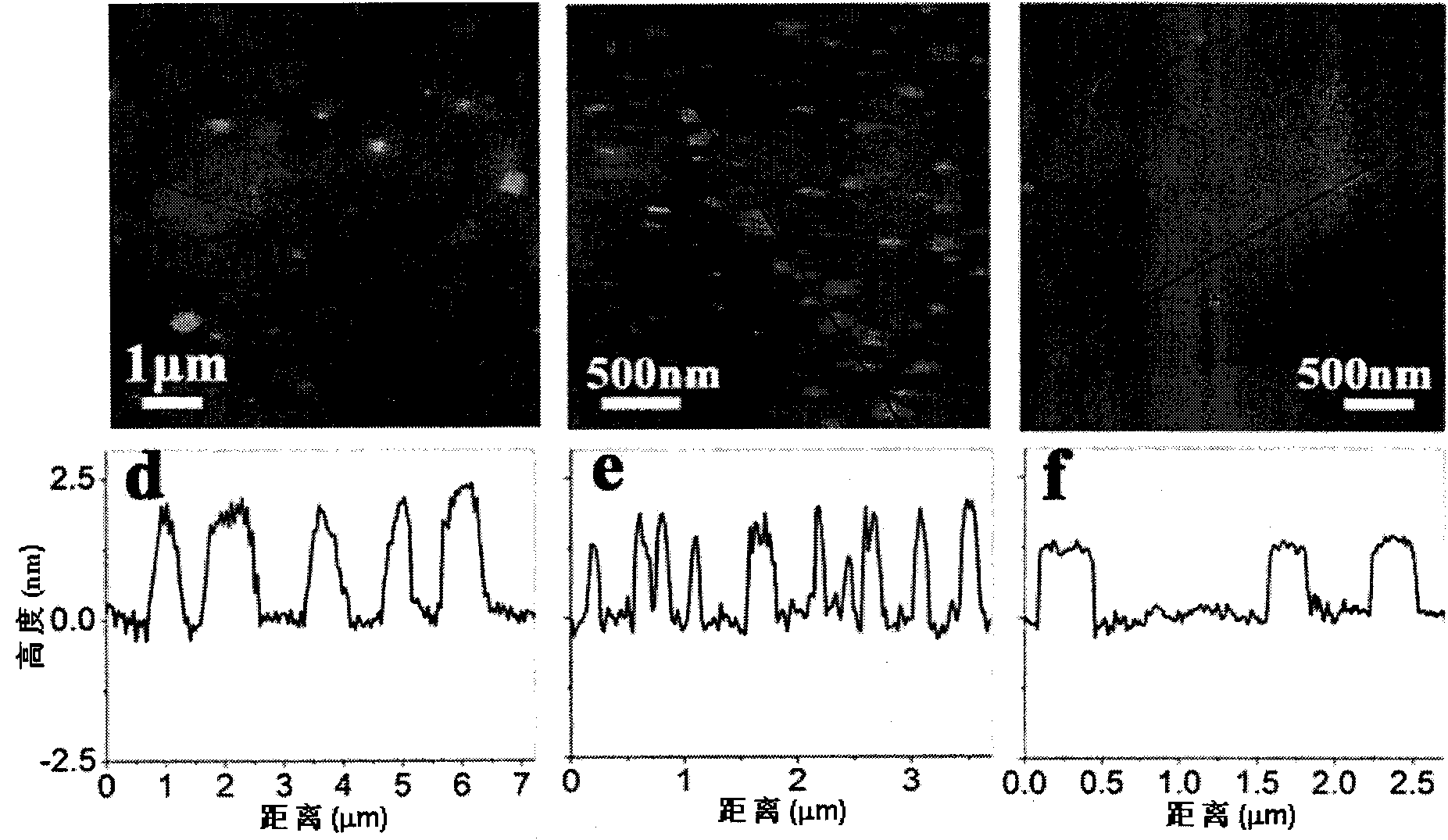

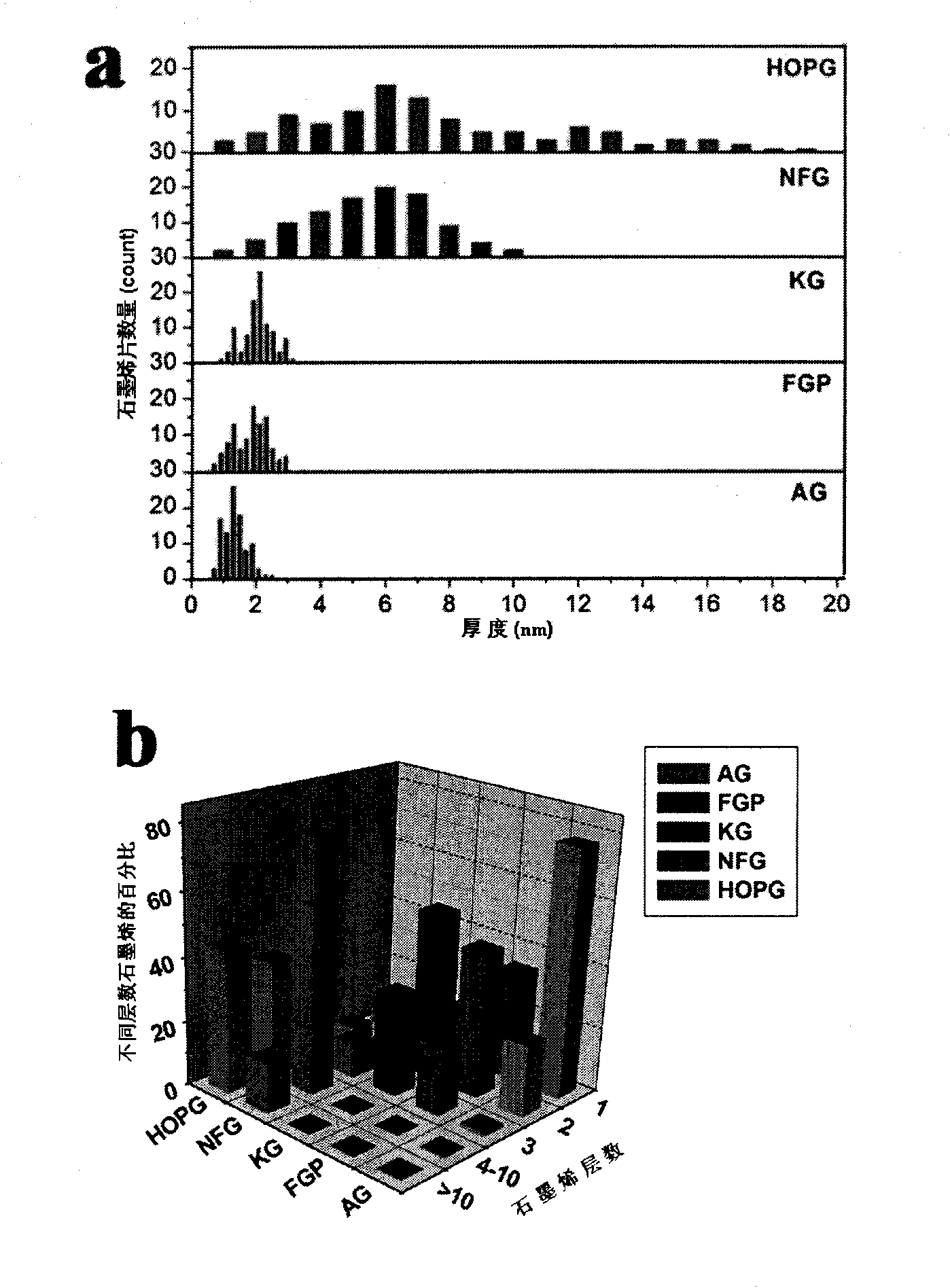

[0026] Observation under an electron microscope shows that the obtained graphene has a smooth surface and a thickness of about 1nm-1.8nm, of which 1 layer accounts for 90%, and 2 layers account for 10%. In thi...

Embodiment 2

[0028] The difference from Example 1 is:

[0029] The artificial graphite powder of size<30 μ m is raw material, and graphite powder average particle size is 20 μ m in the present embodiment; Adopt Hummer method to oxidize 5h; Be heated to expansion temperature 1050 ℃ rapidly with 35 ℃ / s heating rate, in argon (flow velocity 200 milliliters / Min) rapid expansion in an atmosphere with a residence time of 20s; reduction at 450°C in a reducing atmosphere of hydrogen (100ml / min) + argon (100ml / min) for 2h; ultrasonic dispersion in NMP at 40°C for 2h, The ultrasonic dispersion power is 400W; the graphite and thick graphite flakes that have not been completely peeled off are removed by high-speed centrifugation at 15,000 rpm.

[0030] Observation under an electron microscope showed that the obtained graphene had a smooth surface and a thickness of about 1 nm-2.4 nm, of which 1 layer accounted for 77%, 2 layers accounted for 22%, and 3 layers accounted for 1%. In the present embodim...

Embodiment 3

[0032]The difference from Example 1 is:

[0033] The natural flake graphite powder of size<30 μm is raw material, and graphite powder average particle size is 20 μm in the present embodiment; Adopt Hummer method to oxidize 5h; Be heated rapidly to expansion temperature 1050 ℃ with 35 ℃ / s heating rate, in argon (flow velocity 200 milliliters Rapid expansion under an atmosphere of 450°C, hydrogen (100ml / min) + argon (100ml / min) for 2h; ultrasonic dispersion in NMP for 2h at 40°C , the ultrasonic dispersion power is 500W; 15,000 rpm high-speed centrifugation is used to remove graphite and thick graphite flakes that have not been completely peeled off.

[0034] Observation under an electron microscope shows that the obtained graphene has a flat surface and a thickness of about 1nm-3nm, of which 1 layer accounts for 34%, 2 layers account for 45%, and 3 layers account for 21%. In the present embodiment, the conductivity of single-layer graphene is 1.1×10 3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com