Preparation method of catalyst dual-assisted two-dimensional transition metal chalcogenide film

A technology of transition metal chalcogenides and compounds, applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as uneven film crystal quality, uncontrollable film thickness, and uneven source partial pressure , to avoid uneven crystal quality, shorten sublimation time, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

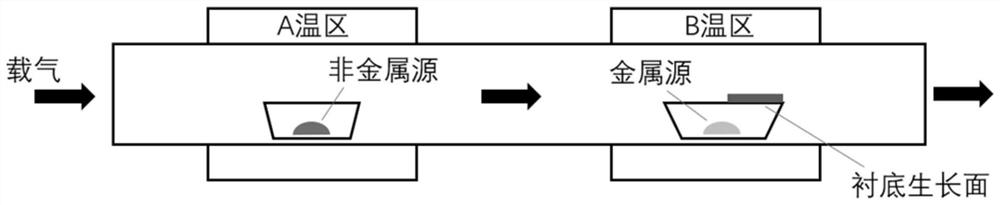

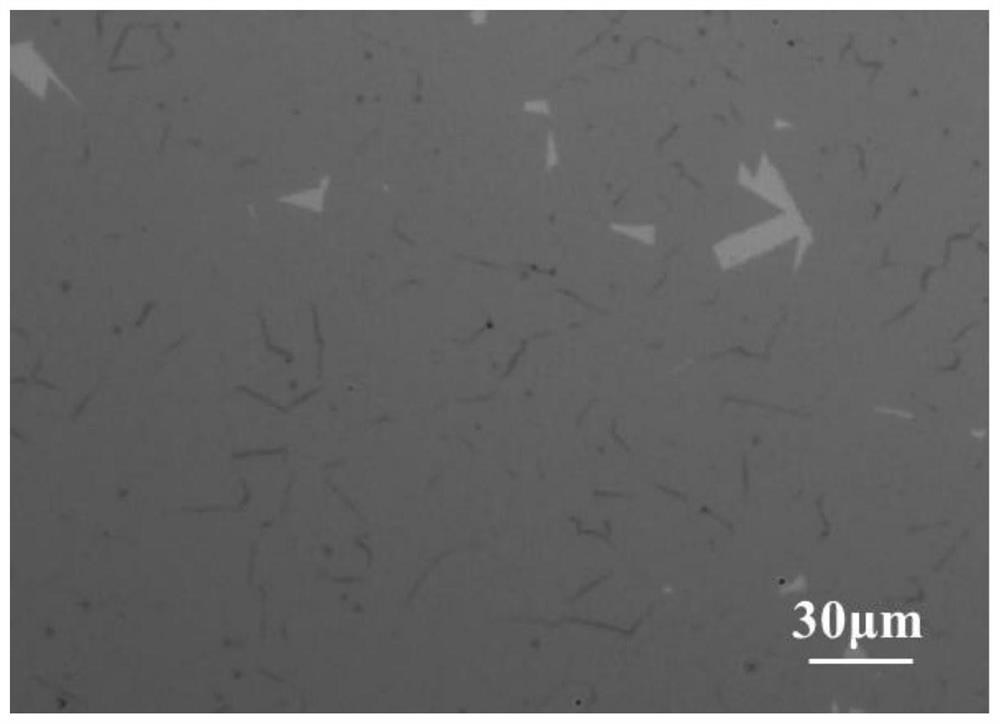

[0042] Preparation of monolayer MoS 2 film, see figure 2 , the specific implementation steps are as follows:

[0043] Step a. Weigh 200mg of sulfur powder in a common crucible and place it in the center of the A temperature zone of the double-temperature zone tube furnace;

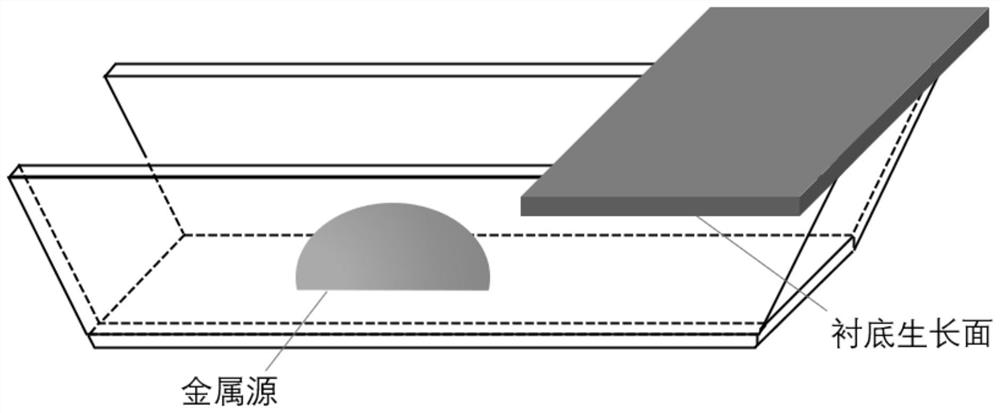

[0044] Step b. 5 mg of solid NaCl was dissolved in 1 mL of deionized water, 10 mg of MoO 3 The powder is poured into this NaCl solution, and after drying the moisture, it is placed in a quartz boat with one end open and one end closed (such as figure 1 shown), and the side wall of the closed end is 2cm apart;

[0045] Step c. On cleaning the SiO 2 SiO / Si substrate2 The surface was spin-coated with 100 μL of 0.3 mmol / L NaCl solution, and dried with a nitrogen gun;

[0046] Step d. Place the substrate on the SiO 2 The closed end of the quartz boat whose one end is open and one end is closed is buckled face down to form a semi-closed structure, and the quartz boat is placed in the center of the B tempe...

Embodiment 2

[0051] Preparation of three-layer MoS 2 The difference between the thin film and Example 1 is that in step c, the concentration of the NaCl solution is 0.5 mmol / L.

Embodiment 3

[0053] Preparation of five-layer MoS 2 The difference between the thin film and Example 1 is that in step c, the concentration of the NaCl solution is 0.8 mmol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com