Modified cellulose nanofiber membrane based on layer-by-layer self-assembly of lysozyme and silk protein based as well as preparation and application thereof

A nanofiber membrane, layer-by-layer self-assembly technology, applied in the fields of polymer materials and biomedical materials, can solve the problem of no biological application, and achieve the effects of low cost of raw materials, controllable number of layers, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

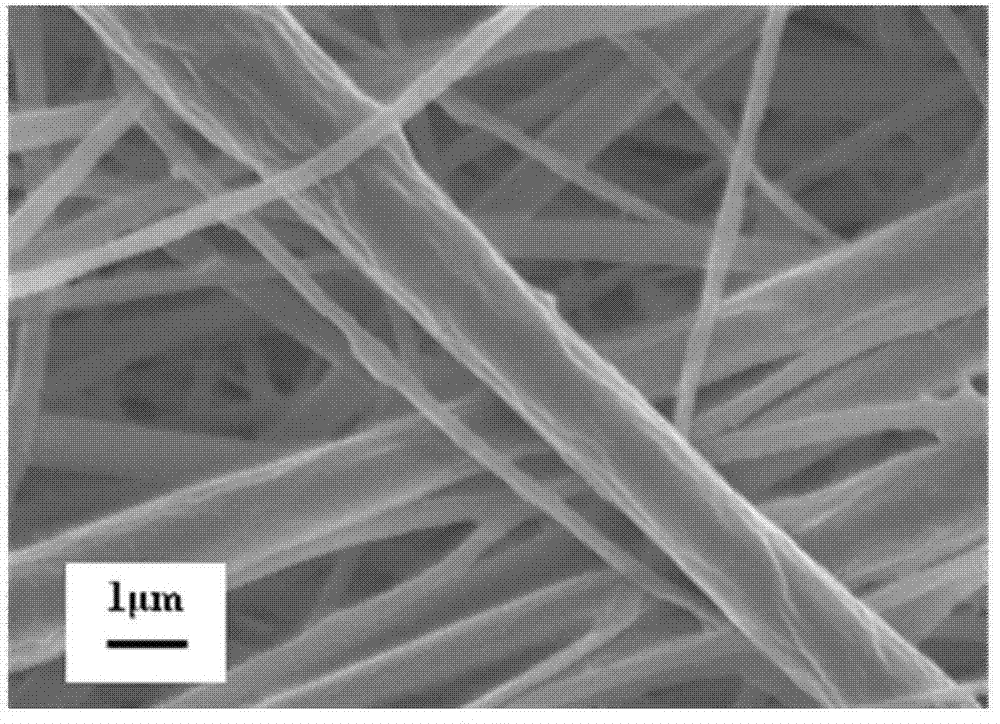

[0029] (1) Prepare cellulose acetate nanofiber membrane by electrospinning technology, that is, dissolve cellulose acetate in acetone / dimethylacetamide (mass ratio 2:1) to prepare 25% (w / w) cellulose acetate solution, the electrospinning voltage was 35kV, the flow rate was 0.5mL / h, the temperature was 5°C, the relative humidity was 20%, and the duration was 96h; then the obtained cellulose nanofiber membrane was hydrolyzed in 0.5M NaOH solution for 7 days.

[0030] (2) At room temperature, soak the prepared cellulose nanofiber membrane in 0.2mg / L lysozyme solution for 5 minutes, then wash it three times with 0.2mg / L NaCl solution, and then wash it in 0.2mg / L silk protein solution Soak for 5 minutes, then wash three times with 0.2mg / L NaCl solution, and assemble in the same way (lysozyme / silk protein) n (n = 30) bilayers to obtain a layer-by-layer self-assembled modified cellulose nanofiber membrane based on lysozyme and silk protein.

Embodiment 2

[0032] (1) Prepare cellulose acetate nanofiber membrane by electrospinning technology, that is, dissolve cellulose acetate in acetone / dimethylacetamide (mass ratio 2:1) to prepare 20% (w / w) cellulose acetate solution, the electrospinning voltage was 20kV, the flow rate was 1mL / h, the temperature was 35°C, the relative humidity was 80%, and the duration was 36h; then the obtained cellulose nanofiber membrane was hydrolyzed in 0.2M NaOH solution for 6 days.

[0033] (2) At room temperature, soak the prepared cellulose nanofiber membrane in 0.1mg / L lysozyme solution for 25 minutes, then wash it three times with 0.1mg / L NaCl solution, and then wash it in 0.1mg / L silk protein solution Soak for 25 minutes, then wash three times with 0.1mg / L NaCl solution, and assemble in the same way (lysozyme / silk protein) n (n=50.5) bimolecular layers to obtain a layer-by-layer self-assembled modified cellulose nanofiber membrane based on lysozyme and silk protein.

Embodiment 3

[0035] (1) Cellulose acetate nanofiber membrane was prepared by electrospinning technology, that is, cellulose acetate was dissolved in acetone / dimethylacetamide (mass ratio 2:1) to prepare 16% (w / w) cellulose acetate solution, the electrospinning voltage was 15kV, the flow rate was 1mL / h, the temperature was 25°C, the relative humidity was 45%, and the duration was 24h; then the obtained cellulose nanofiber membrane was hydrolyzed in 0.1M NaOH solution for 7 days.

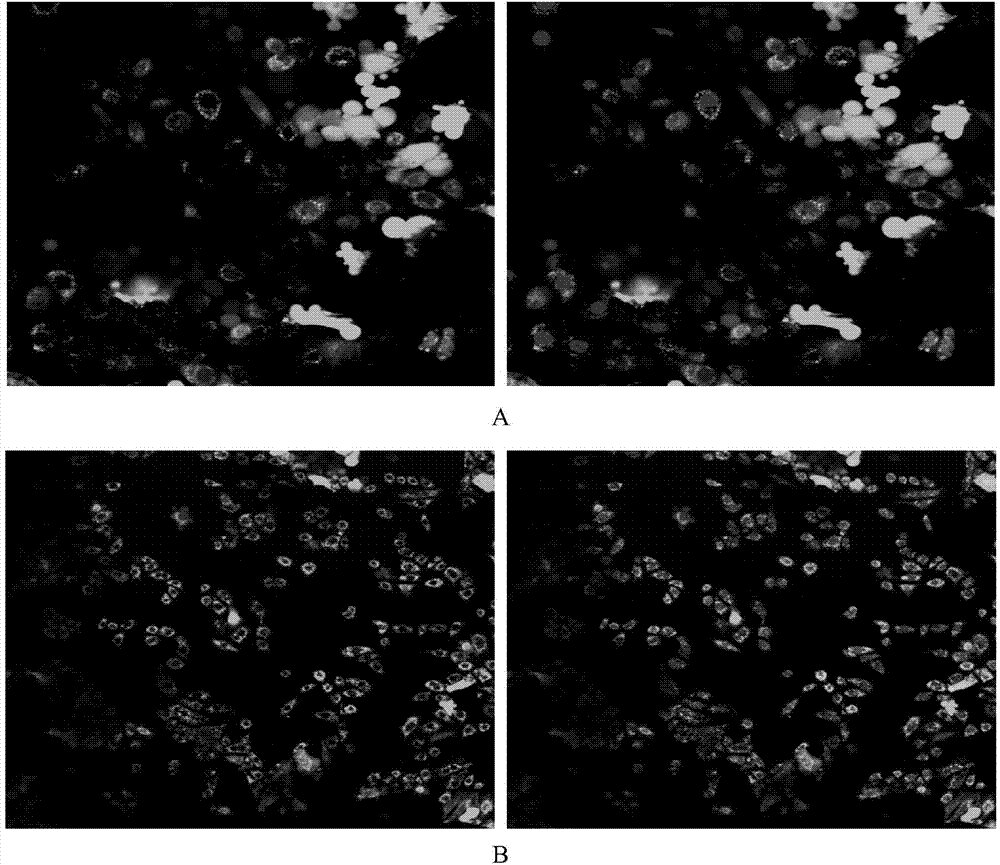

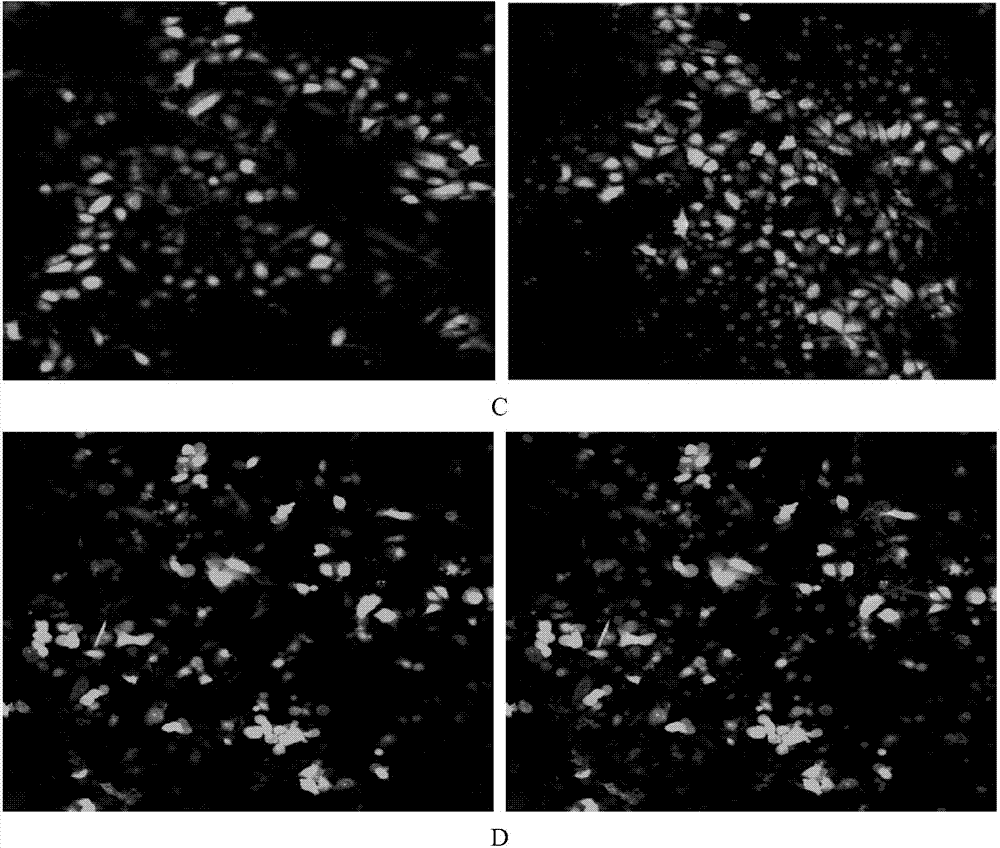

[0036] (2) At room temperature, soak the prepared cellulose nanofiber membrane in 0.1mg / L lysozyme solution for 20 minutes, then wash it three times with 0.1mg / L NaCl solution, and then wash it in 0.1mg / L silk protein solution Soak in water for 20 minutes, then wash three times with 0.1mg / L NaCl solution, and assemble in the same way (lysozyme / silk protein) n (n = 5) bilayers to obtain a layer-by-layer self-assembled modified cellulose nanofiber membrane based on lysozyme and silk protein. The morphology of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com