Composite film for flow energy storage battery and application thereof

A liquid flow energy storage battery and composite membrane technology, which is applied to battery pack components, fuel cell components, circuits, etc., can solve problems such as limiting hydrogen ion transmission, achieve good comprehensive performance, improve ion selection ability, and prepare Process clean and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 7.5 grams of polyacrylonitrile in 50ml of DMSO, stir for 5 hours, spread the polymer solution on a glass plate, then quickly immerse in 5L of water, solidify, and form a porous membrane. The prepared porous membrane is soaked in deionized water 1 hour.

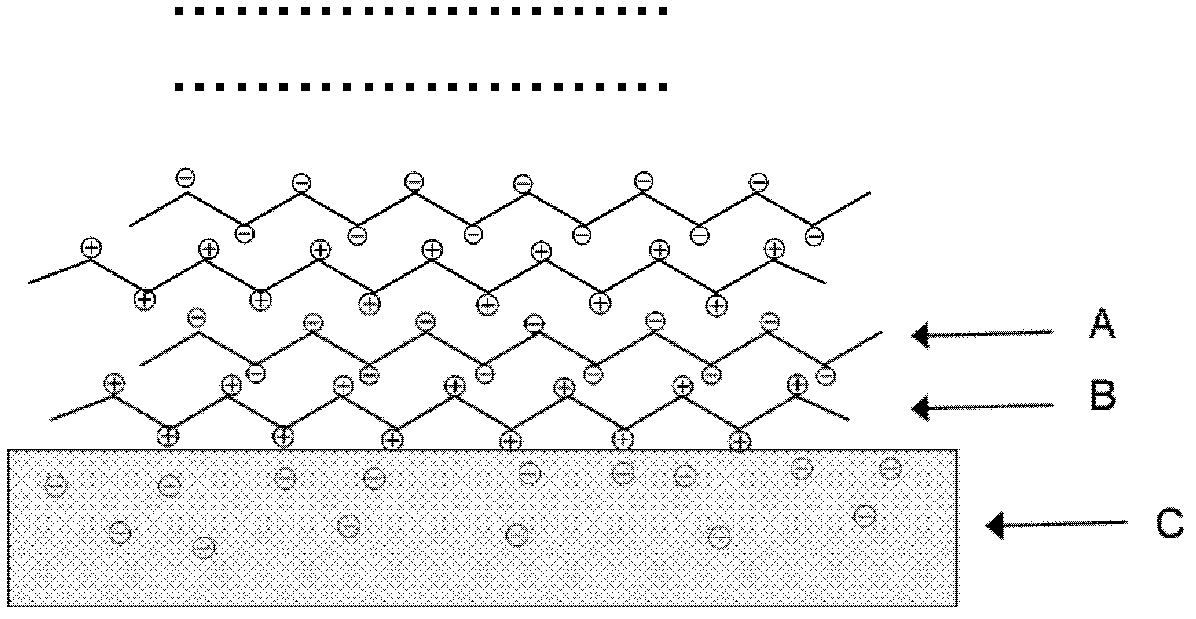

[0038] The porous membrane prepared by the above steps is placed in 0.5wt.% polydipropylene dimethyl ammonium chloride (PDDA) aqueous solution, left to stand for 5 minutes, taken out and rinsed with deionized water; then the membrane is placed in 0.5wt.% sulfonated polyether ether ketone (SPEEK) aqueous solution, let it stand for 5 minutes, take it out and rinse it with deionized water; after that, soak it in the above-mentioned PDDA and SPEEK solution alternately for 4 times in the same way to obtain the self- The self-assembled layer with 12 assembled layers is composited with a porous film.

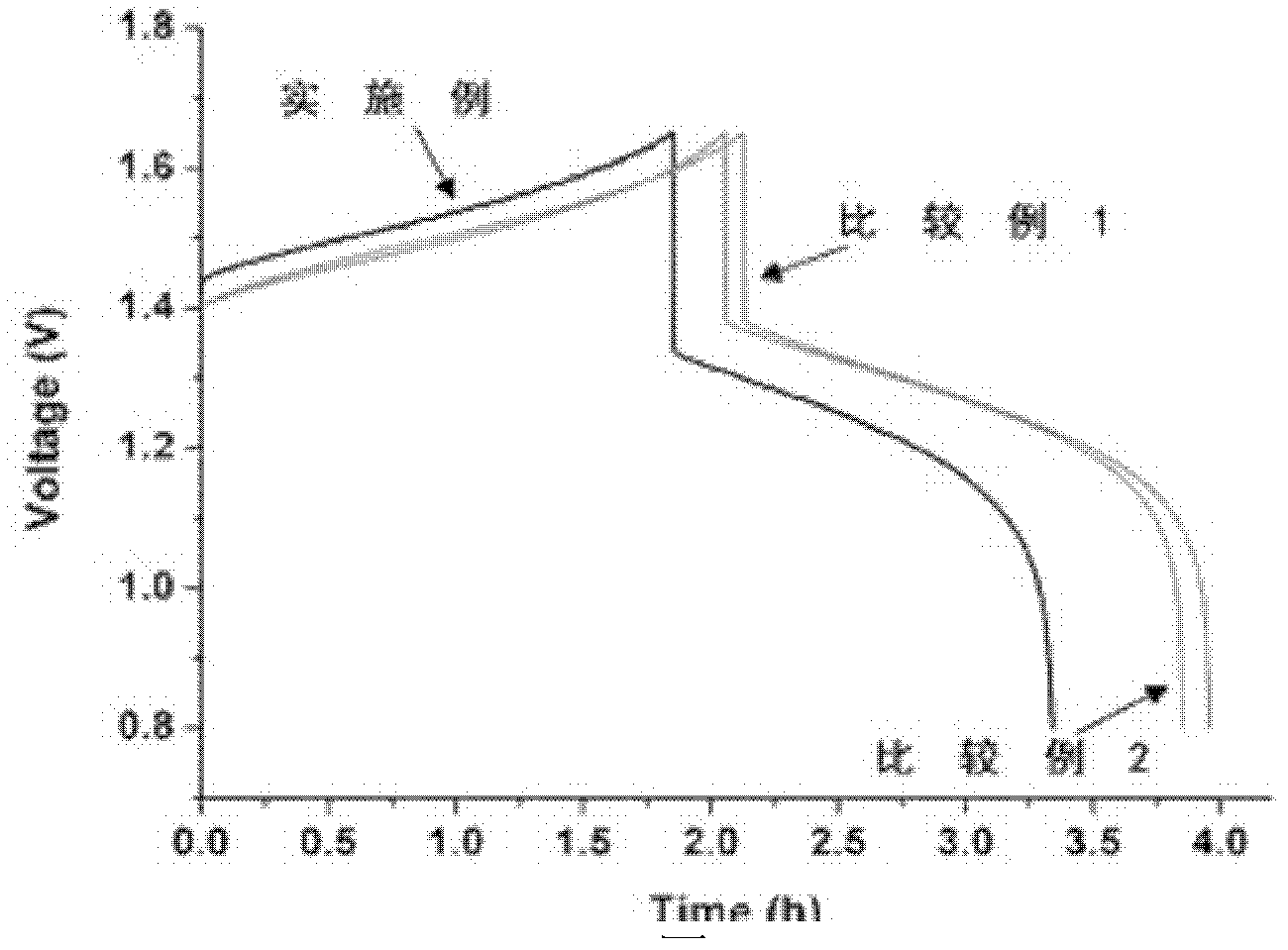

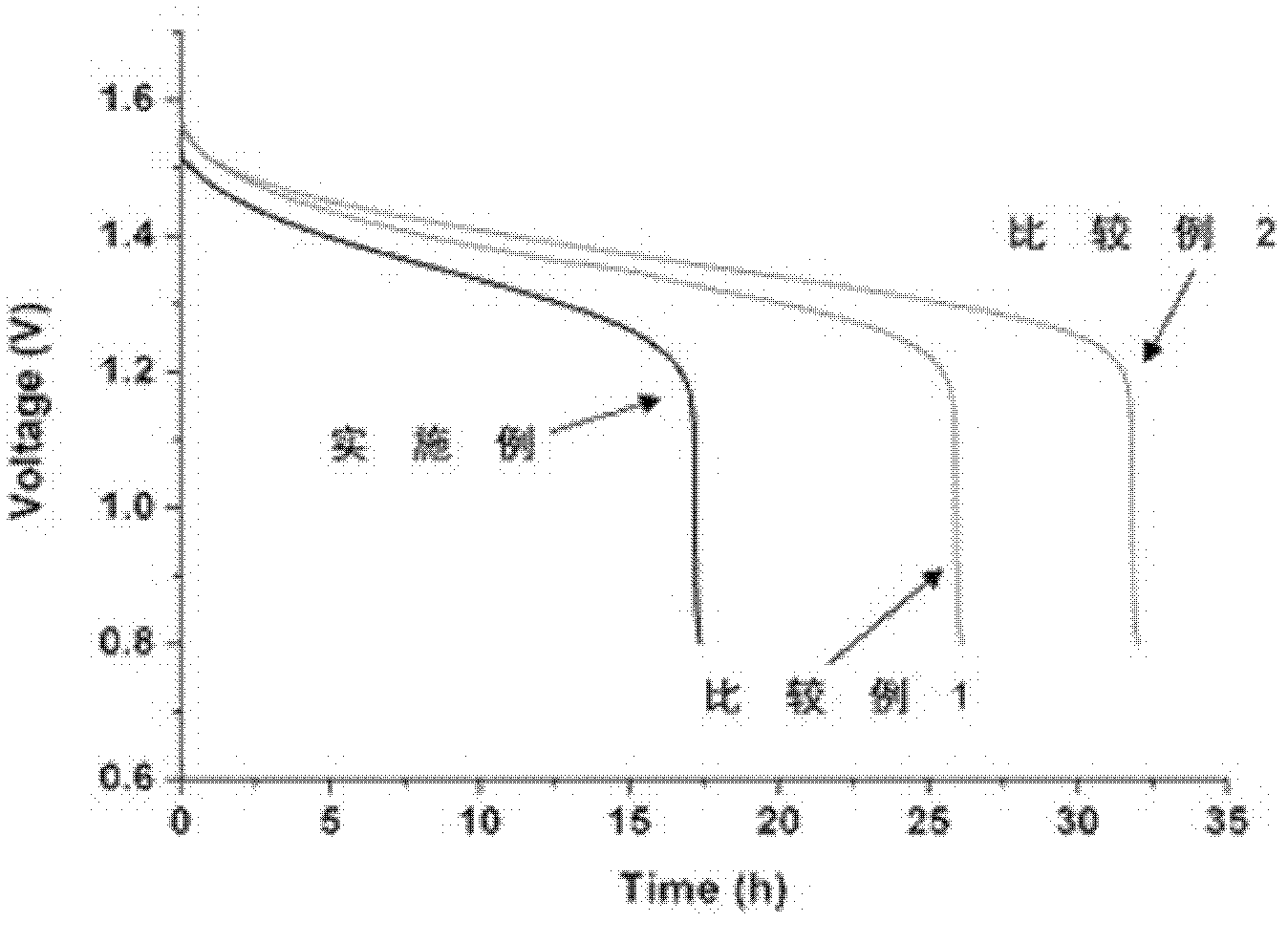

[0039] The all-vanadium flow energy storage battery is assembled by using the prepared self-assembled layer composit...

Embodiment 2

[0041]The preparation method of the self-assembled composite porous film is the same as in Example 1, and the number of self-assembled layers is 20, and the battery is assembled with the composite film. Other assembly conditions and test conditions are the same as in Example 1. The battery Coulombic efficiency is 87.0%, the voltage efficiency is 83.3%, and the energy efficiency is 72.5%. The self-discharge time was 32.0 hours.

Embodiment 3

[0048] The SPEEK solution in Example 1 was replaced with a sulfonated polysulfone (SPU) solution, and a composite porous membrane with 30 self-assembled layers was prepared by the same preparation method, so as to assemble a battery. Other assembly conditions and test conditions are the same as in Example 1. The battery Coulombic efficiency is 88.3%, the voltage efficiency is 81.4%, and the energy efficiency is 71.9%. The self-discharge time was 38.3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com