Patents

Literature

46results about How to "The preparation process is clean and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

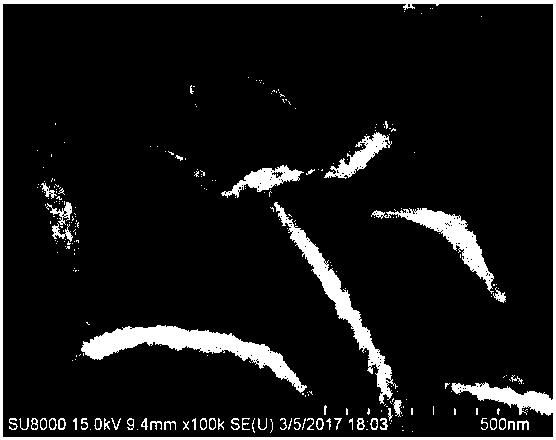

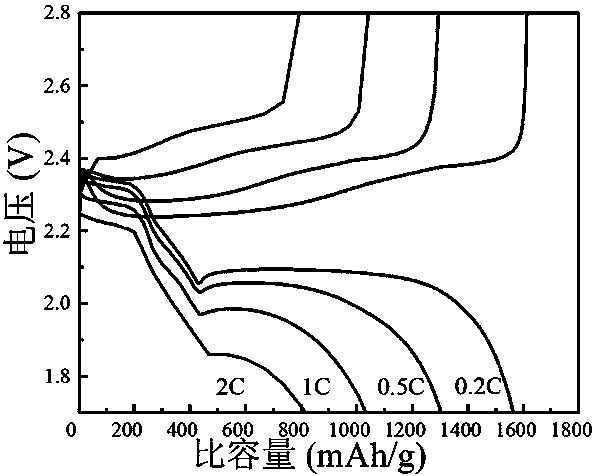

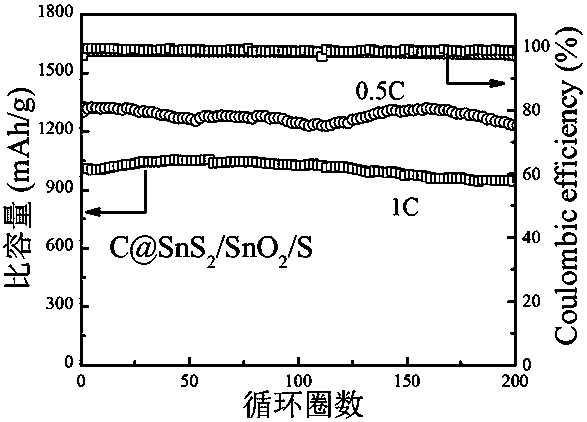

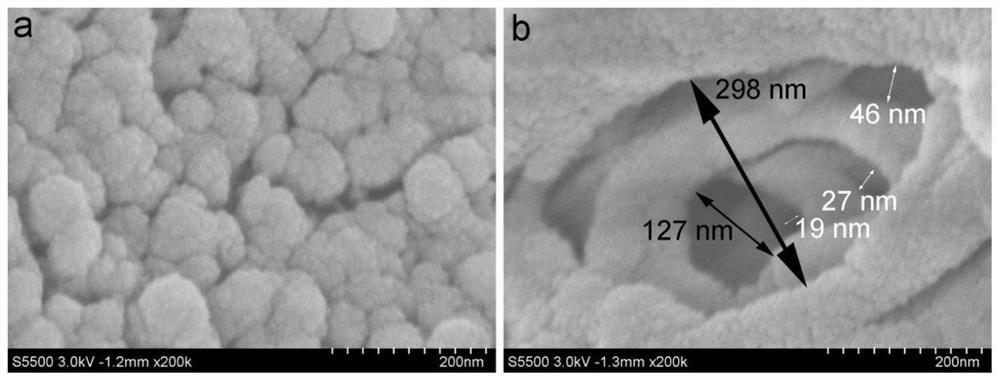

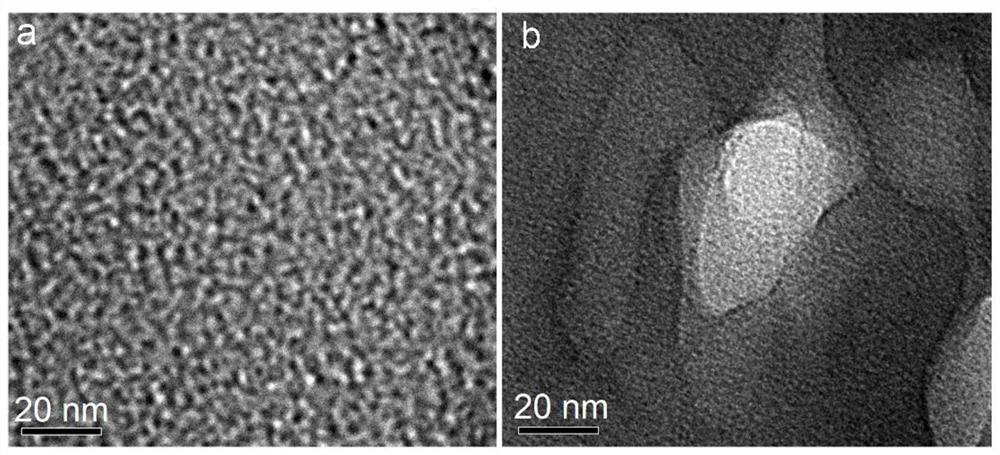

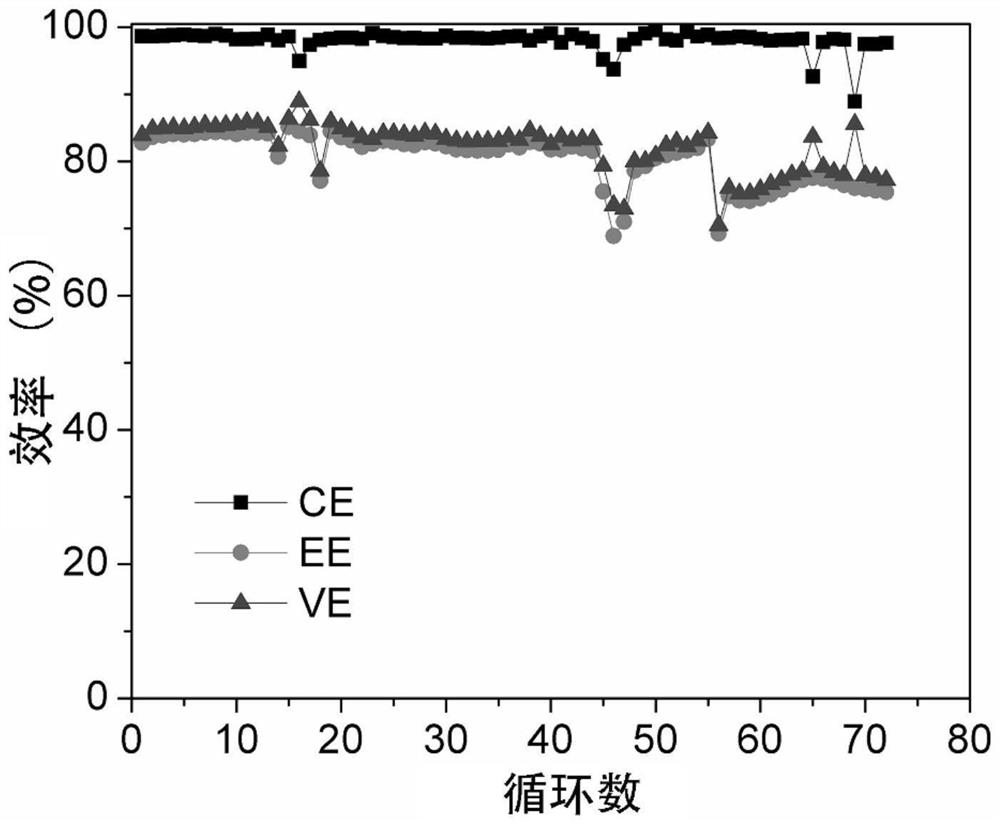

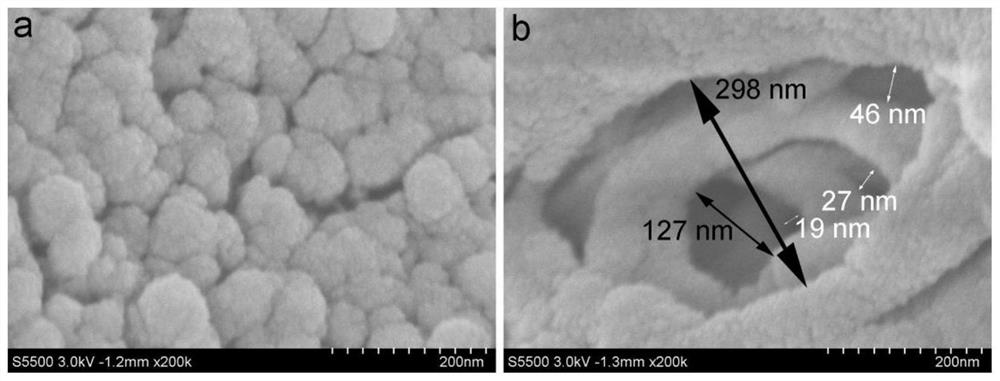

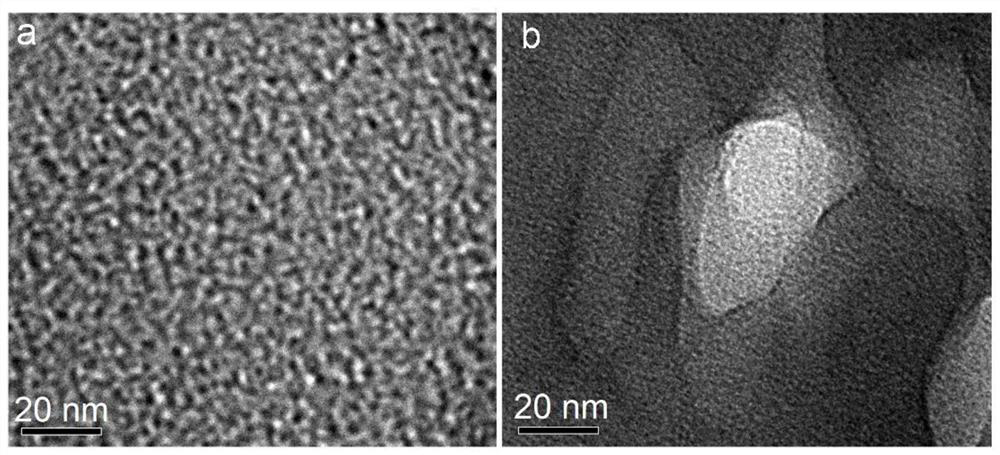

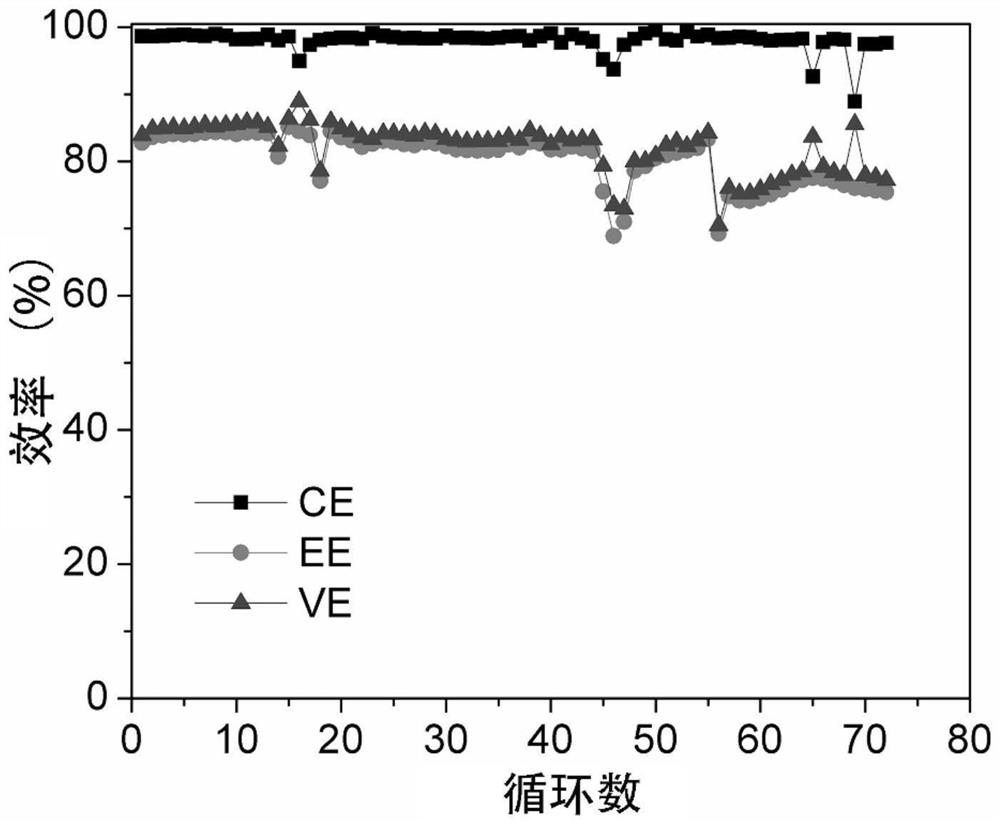

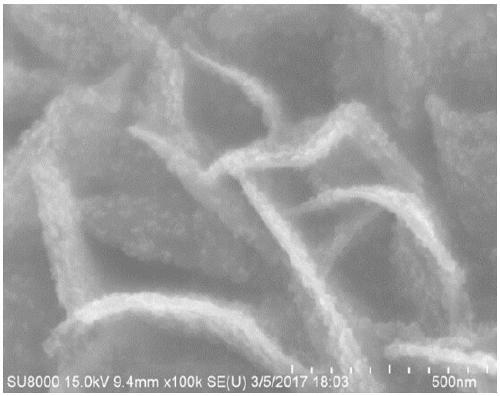

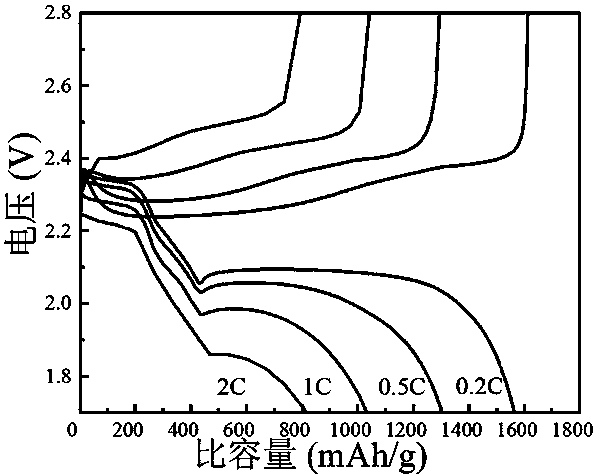

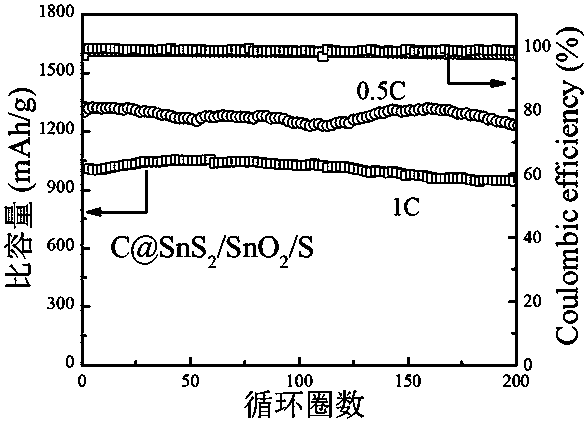

Preparation method and application of carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with heterojunction structure

ActiveCN107768620AGood adsorption capacity of lithium polysulfideImprove stabilityMaterial nanotechnologyLi-accumulatorsHeterojunctionTin dioxide

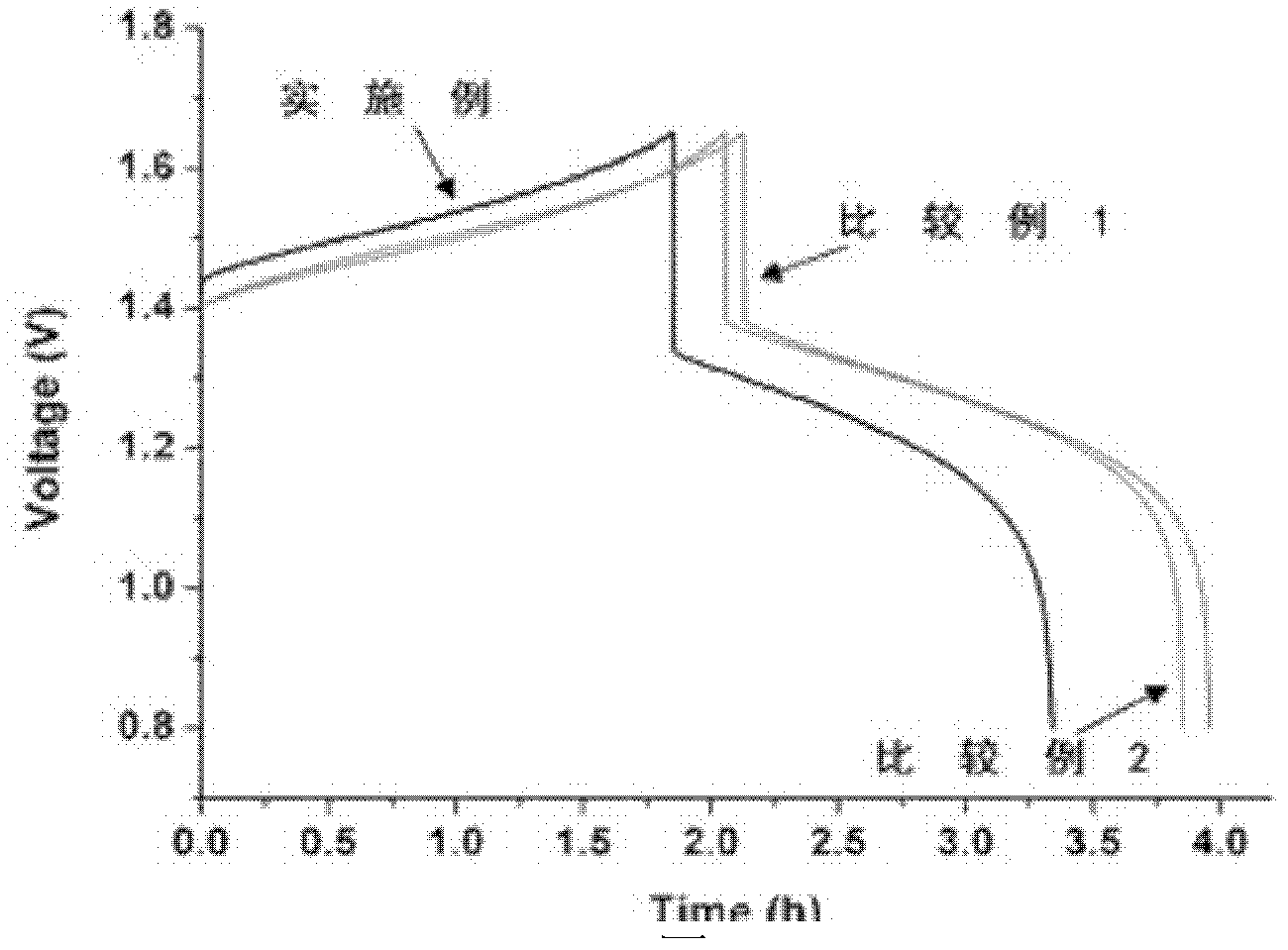

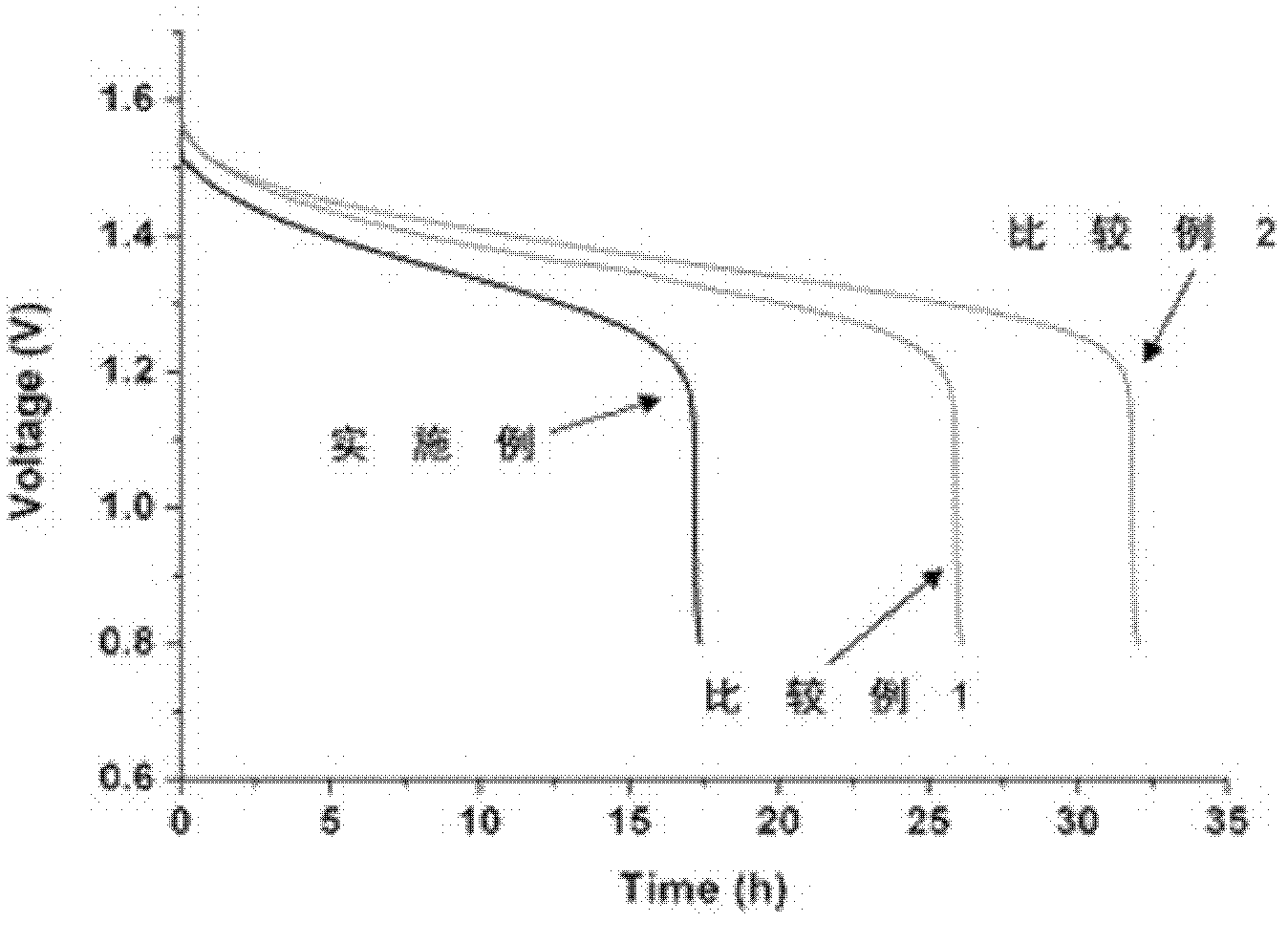

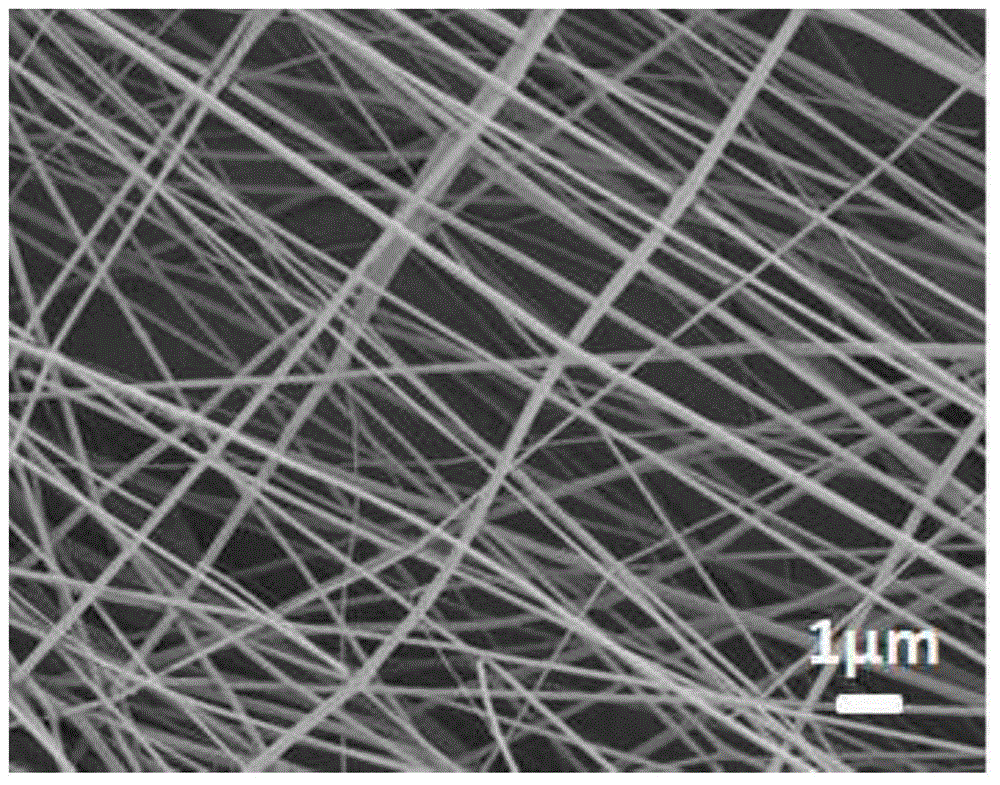

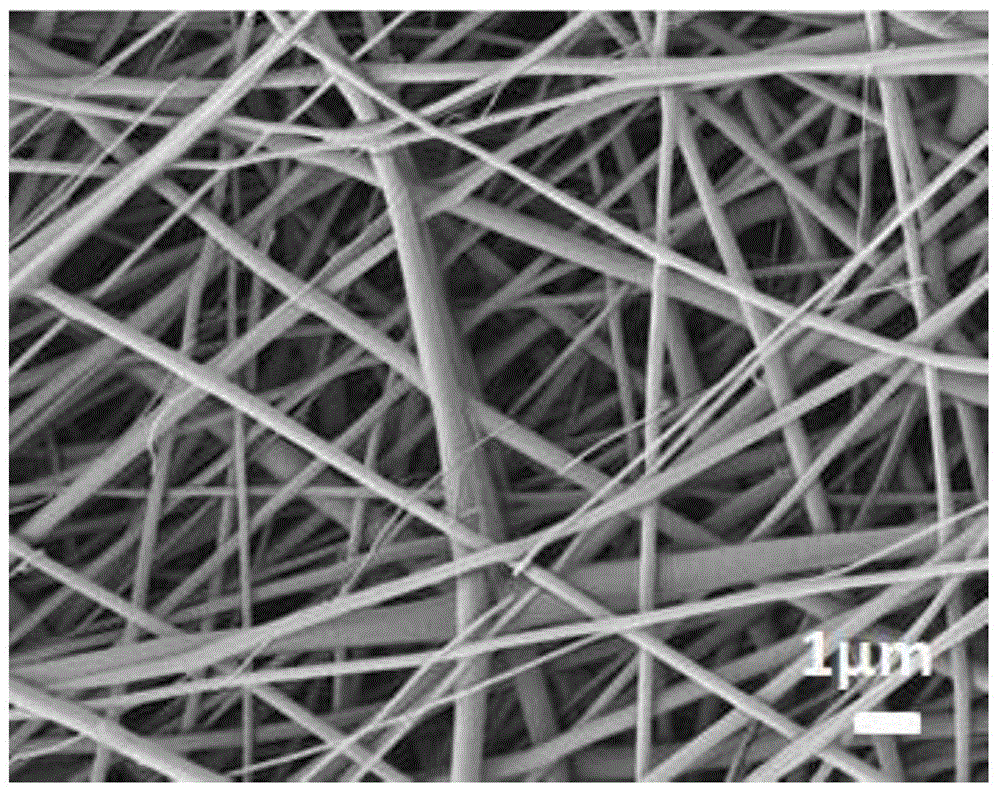

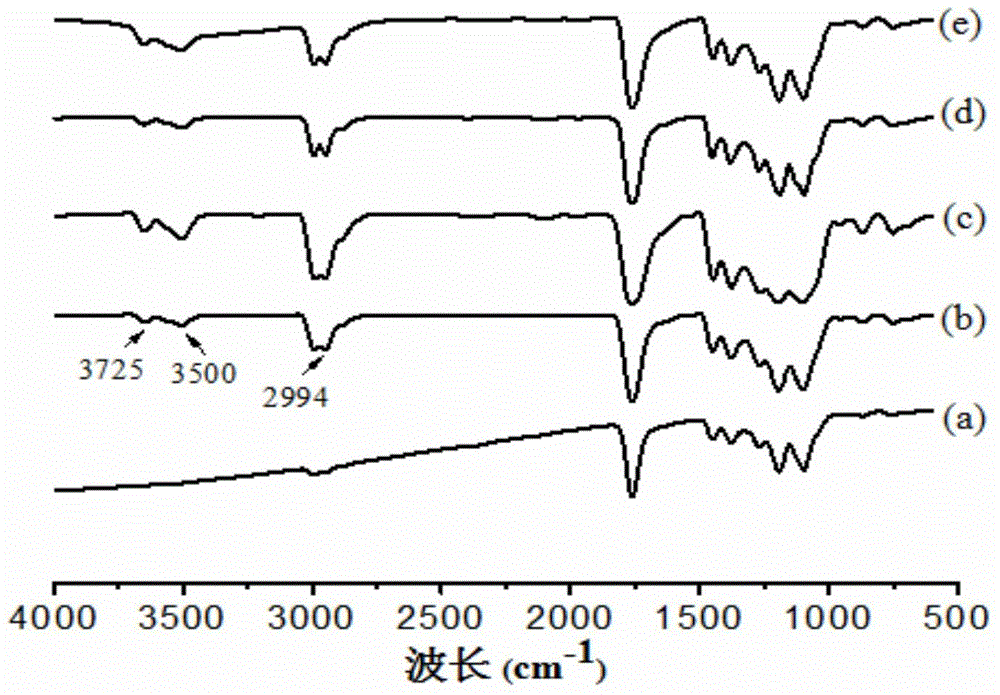

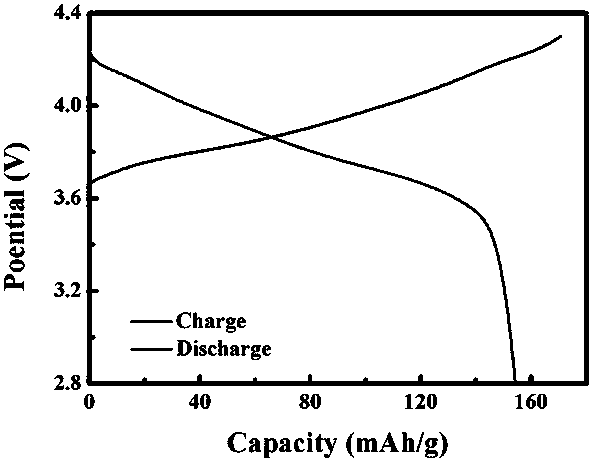

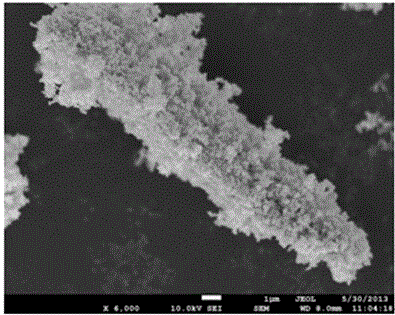

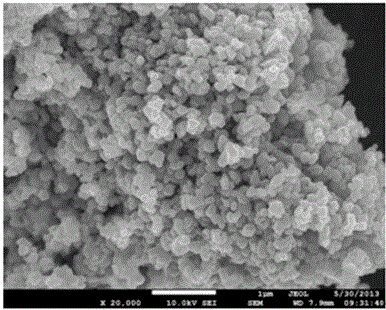

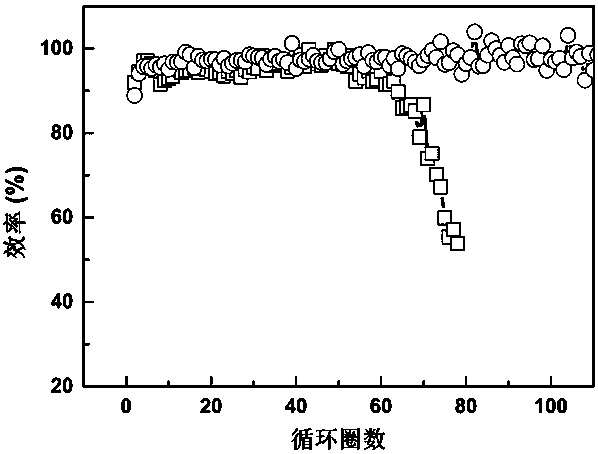

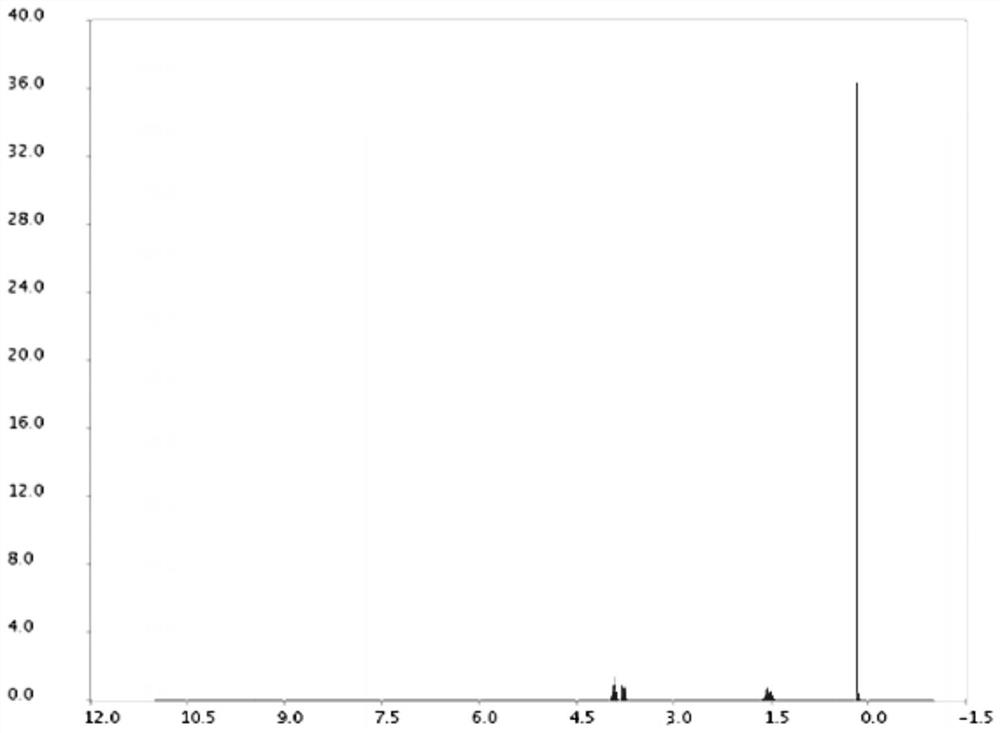

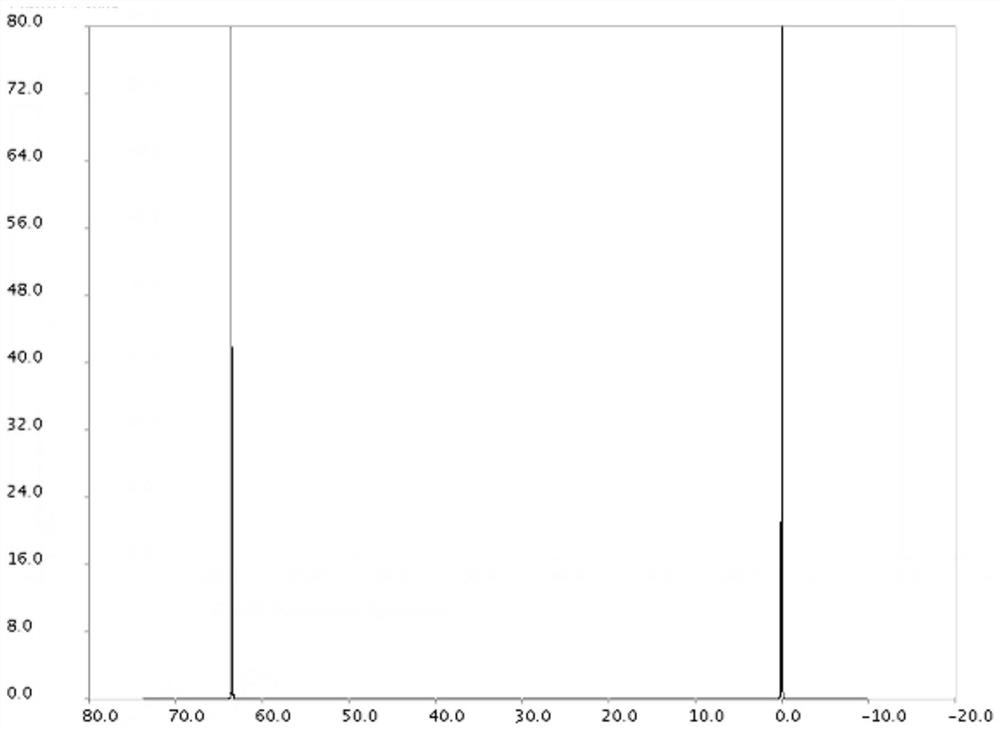

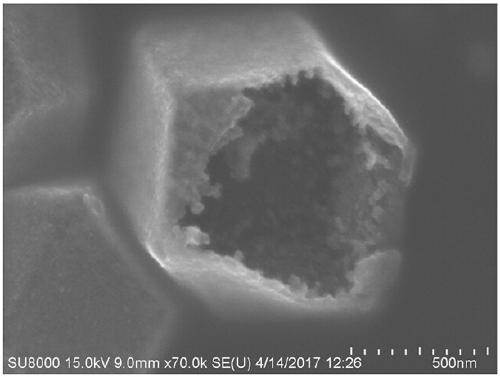

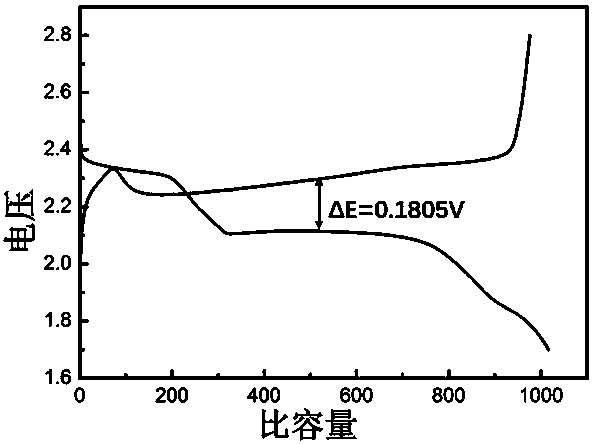

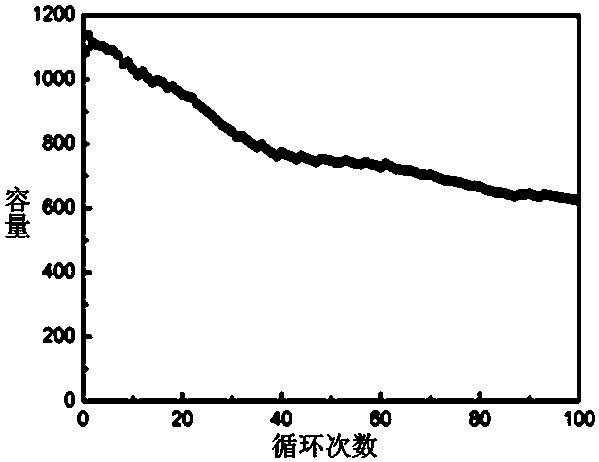

The invention relates to a preparation method and application of a carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with a heterojunction structure, and belongs to the technical field of an energy material. The method comprises the following steps: 1, dissolving tin tetrachloride, thioacetamide and carbon nanofiber into polypropyl alcohol and performing hydrothermal reaction to obtain a carbon nanofiber, tin disulfide and tin dioxide composite material with the heterojunction structure; 2, dipping the composite material obtained in the step 1 into a sulfur solution, taking out after 5 minutes, vacuum-drying and calcining at high temperature to obtain the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure. The preparation method and the application of the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure have the following advantages: the composite material has special interface effect, can effectively increase electrode surface electron and ion transmission speed and is favorable for realize efficient utilization of the sulfur and obtainingthe cyclic stable lithium sulfur battery. The composite material can be prepared by directly utilizing a one-step hydrothermal method, the preparation method is simple and practical, and the components are controllable.

Owner:HARBIN INST OF TECH

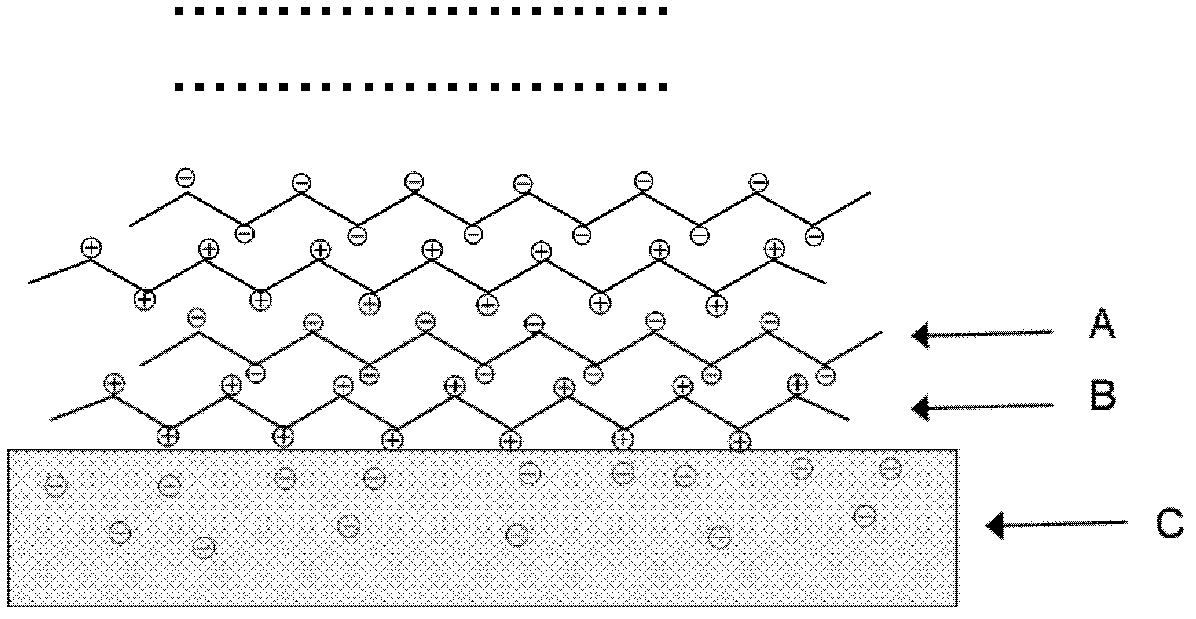

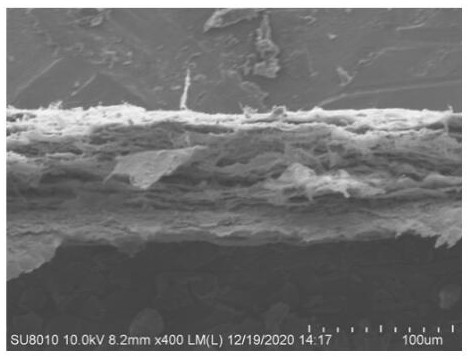

Composite film for flow energy storage battery and application thereof

InactiveCN102867928AHigh ion selectivityImprove hydrophilicitySynthetic resin layered productsCell component detailsComposite filmOrganic polymer

The invention discloses a composite film for a flow energy storage battery and an application of the composite film in the flow energy storage battery. The composite film disclosed herein is characterized by using one or more than two of organic polymer resin or sulfonated polymer resin as raw material to prepare a porous film as a matrix, and successively alternately self-assembling cationic polymer resin and anion polymer resin layer by layer on the surface of the matrix by static electricity to form the composite film. The composite film disclosed herein has the advantages of simple preparation method, environmentally friendly process, controllable number of assembling layers, and adjustable ionic selectivity. Compared with original porous films, the composite film disclosed herein has good hydrophilicity and vanadium ion blocking ability, and an all vanadium flow energy storage battery assembled by using the composite film has higher efficiency and longer self-discharge time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

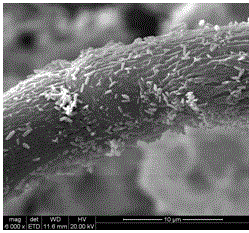

Nanometer microcrystalline cellulose reinforcing polylactic acid glycolic acid electrospun membrane, preparation method thereof and application

InactiveCN104532480AIncrease the areaHigh porosityElectro-spinningNon-woven fabricsWound healingElectrospinning

The invention discloses a nanometer microcrystalline cellulose reinforcing polylactic acid glycolic acid electrospun membrane, a preparation method thereof and application and relates to the field of biomedicine. Two natural organic polymer materials of PLGA and CNCs are composited, the method of preparing the electrospun film through electrospinning can effectively enhance the strength and the bioactivity of the materials, give full play to the biological nanometer effect and effectively compensate for the limitation of pure PLGA in biomedical application, and wound healing is well facilitated. In addition, the CNCs reinforcing PLGA electrospun membrane prepared through the method can also be used in fields of medicine controlled slow-release, repair of organs, such as skin, nerve and heart, tissue regeneration and the like.

Owner:BEOGENE BIOTECH GUANGZHOU

Preparation method and application of nanometer LiF/Fe/graphite positive electrode lithium supplementing slurry

InactiveCN110176641AHigh specific capacityAppropriate decomposition voltageSecondary cells servicing/maintenanceHigh energySlurry

The invention discloses a preparation method and an application of nanometer LiF / Fe / graphite positive electrode lithium supplementing slurry; the method comprises the following steps of 1, performingmixing and uniform stirring on LiF, Fe powder and graphite; and step 2, enabling the uniformly mixed LiF, Fe powder and graphite to be added into absolute ethyl alcohol and then transferring the mixture into a high-energy ball milling tank, and carrying out high-energy ball milling under the protection of inert gas to obtain the nanometer LiF / Fe / graphite positive electrode lithium supplementing slurry. By adoption of the method, the obtained nanometer LiF / Fe / graphite positive electrode lithium supplementing slurry can be applied to a lithium ion battery positive electrode for lithium supplementing. After the lithium ion battery is charged to 4.5V for the first time, LiF reacts with Fe to generate FeF3, and Li+ is released; and when the lithium ion battery is discharged to 3.0V, FeF3 does not return to LiF and Fe, and the redundant Li+ is used for compensating Li+ consumption caused by formation of an SEI membrane and lithium loss in subsequent circulation. The preparation method disclosed by the invention is low in raw material cost and simple in preparation process, and the preparation process is clean and environment-friendly.

Owner:HARBIN INST OF TECH

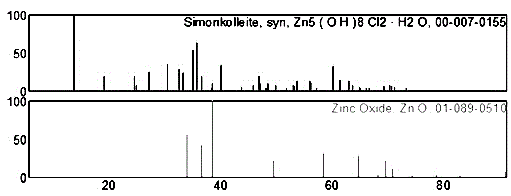

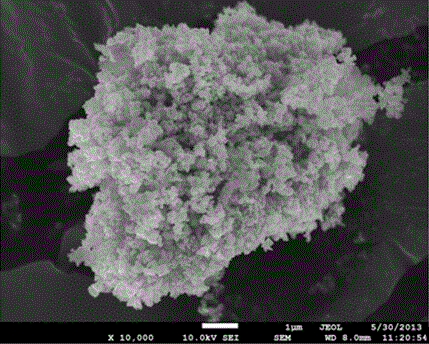

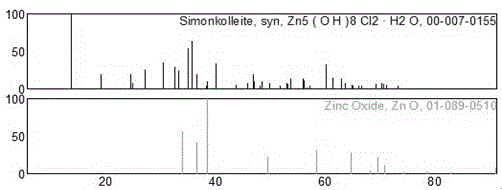

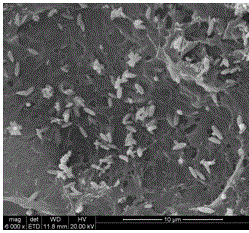

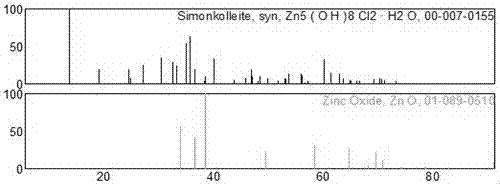

Preparation method for strip-type nano ZnO/cellulose gel material

ActiveCN104941537AThe preparation process is clean and environmentally friendlyPromote generationMaterial nanotechnologyColloidal chemistry detailsSolventIon

The invention discloses a preparation method for a strip-type nano ZnO / cellulose gel material. A ZnCl2 aqueous solution is used as a solvent for cellulose and a zinc source for nano ZnO; dissolving pulp cellulose fibers are cellulose raw materials; the strip-type nano ZnO / cellulose gel material is prepared by dissolving, co-separation, hydrothermal synthesis and freeze drying. As the ZnCl2 aqueous solution is ingeniously used as the solvent for the cellulose and the zinc source for nano ZnO, other cellulosesolvents are not needed to be added, and the preparation technology is clean and environment-friendly; furthermore, after cellulose is dissolved, hydroxyl on the molecules of the cellulose is combined with zinc ions, so that generation of nano ZnO is promoted, and the hydrothermal synthesis temperature is correspondingly obviously reduced; therefore, the preparation technology has the advantage of energy conservation.

Owner:NANJING FORESTRY UNIV

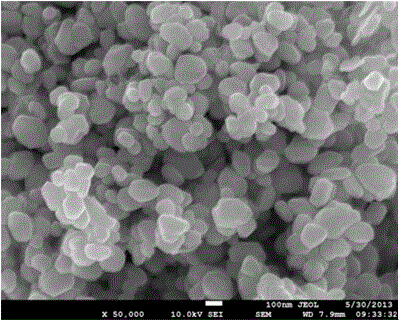

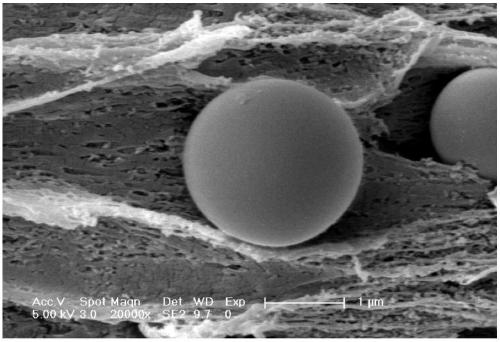

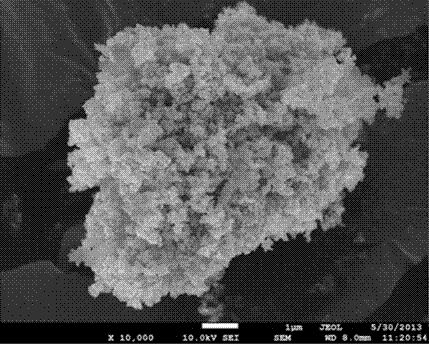

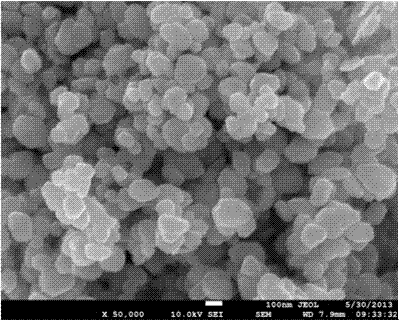

Nano ZnO/cellulose gel particles and preparation method thereof

ActiveCN104941540AThe preparation method hasThe preparation process is clean and environmentally friendlyMicroballoon preparationMicrocapsule preparationFreeze-dryingCellulose fiber

The invention discloses nano ZnO / cellulose gel particles and a preparation method thereof. According to the nano ZnO / cellulose gel particles, cellulose gel is used as a core, and the outer layer is loaded with nano ZnO. According to the preparation method, a ZnCl2 aqueous solution is used as a solvent for cellulose and a zinc source for nano ZnO; dissolving pulp cellulose fibers are cellulose raw materials; the nano ZnO / cellulose gel particles are prepared by dissolving, co-separation, hydrothermal synthesis and freeze drying. As the ZnCl2 aqueous solution is ingeniously used as the solvent for the cellulose and the zinc source for nano ZnO, other cellulosesolvents are not needed to be added, and the preparation technology is clean and environment-friendly; furthermore, after cellulose is dissolved, hydroxyl on the molecules of the cellulose is combined with zinc ions, so that generation of nano ZnO is greatly promoted, and the hydrothermal synthesis temperature is correspondingly obviously reduced; therefore, the preparation technology has the advantage of energy conservation.

Owner:NANJING FORESTRY UNIV

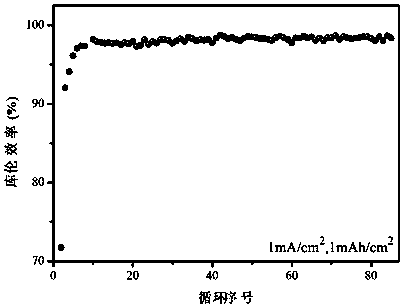

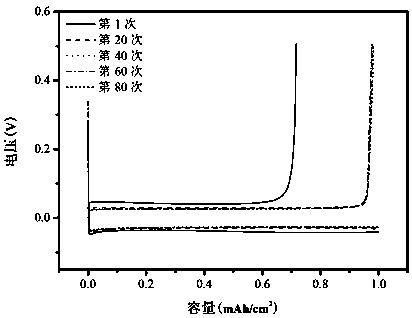

Preparation method and application of protective layer used for metal lithium anode

ActiveCN109326798AHigh crystallinityGood chemical stabilityElectrode carriers/collectorsSecondary cellsPotassium ferricyanideCopper foil

The invention discloses a preparation method of a protective layer used for a metal lithium anode and application of the protective layer used for the metal lithium anode. The method comprises the following steps that 1, clean copper foil is immersed in a solution containing potassium ferricyanide, PVP and hydrochloric acid for reaction to obtain a copper foil current collector with a surface containing prussian blue film; 2, an aqueous solution containing graphene oxide is subjected to dispensing or spin-coating or self-assembly on the surface of the copper foil current collector obtained inthe step 1, and after room-temperature drying is conducted, a current collector with graphene oxide / prussian blue compound film is obtained. The current collector with the graphene oxide / prussian bluecompound film prepared through the method can be applied into the metal lithium anode. The graphene oxide / prussian blue compound current collector prepared through the method is beneficial for diffusion and transferring of lithium ions and electrons, metal lithium volume change and generation of lithium dendrites in charge and discharge processes are relieved, and dead lithium generation and diaphragm impaling are avoided, so that the recycling and rate performance of the metal lithium anode is improved.

Owner:HARBIN INST OF TECH

Hierarchical porous polylactic acid material and preparation method thereof

ActiveCN109370179AImprove connectivityImprove mechanical propertiesHierarchical porousMechanical property

The invention relates to a hierarchical porous polylactic acid material and a preparation method thereof, belongs to the technical field of biodegradable polymer porous materials and solves the technical problems that an existing porous polylactic acid material is single in pore diameter, poor in mechanical strength and poor connectivity among pores and a pore structure is difficult to control dueto the introduction of an organic solvent in a preparation method of the existing porous polylactic acid material. The hierarchical porous polylactic acid material disclosed by the invention is prepared by taking polylactic acid as a matrix, the matrix is irregularly distributed with a plurality of micropores and macropores which are in a form of olive-shaped pores or round pores, and long axes of the olive-shaped pores are parallel when both the micropores and the macropores are in the form of the olive-shaped pores. The porous polylactic acid material simultaneously has the micropores and the macropores, the connectivity among the pores is relatively good, the micropores can be interconnected with the macropores, the porosity can reach up to 80% or above, and the mechanical properties are good.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

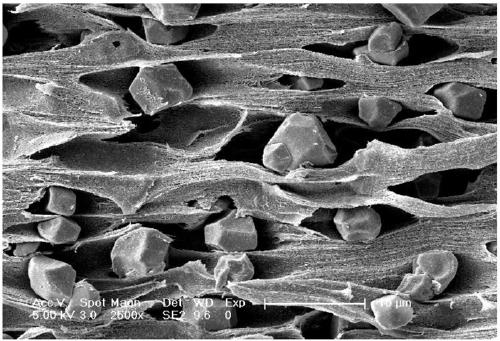

A kind of nano-micro ZnO/composite cellulose strip material and preparation method thereof

ActiveCN104941683BThe preparation process is clean and environmentally friendlyPromote generationMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceFreeze-drying

The invention discloses a method for preparing nano-micro ZnO / composite cellulose strip materials. ZnCl2 aqueous solution is used as the swelling agent and solvent of cellulose and the zinc source of nano-ZnO, and the cellulose fiber of the dissolved pulp is used as the cellulose raw material. Swelling and partial dissolution, injection co-precipitation, hydrothermal synthesis and freeze-drying prepared nano-micro ZnO / cellulose strips supported by raw cellulose fibers and regenerated cellulose fibers. Since the present invention uses the ZnCl2 aqueous solution as the swelling agent and solvent of the cellulose and the zinc source of the nano-ZnO, there is no need to add other cellulose solvents, and the preparation process is clean and environment-friendly. In addition, after the cellulose is swelled and partially dissolved, the hydroxyl groups on its molecules combine with zinc ions, which promotes the formation of nano-ZnO, and the hydrothermal synthesis temperature is also significantly reduced accordingly. Therefore, the preparation process has the advantage of energy saving.

Owner:NANJING FORESTRY UNIV

A kind of nano-zno/cellulose gel particle and preparation method thereof

ActiveCN104941540BThe preparation method hasThe preparation process is clean and environmentally friendlyMicroballoon preparationMicrocapsule preparationFreeze-dryingCellulose fiber

The invention discloses a nanometer ZnO / cellulose gel particle and a preparation method thereof. The nanometer ZnO / cellulose gel particle uses cellulose gel as a core, and the outer layer is loaded with nanometer ZnO. In the preparation method, ZnCl2 aqueous solution is used as the solvent of cellulose and the zinc source of nano-ZnO, and the pulp cellulose fiber is used as the cellulose raw material, and the nano-ZnO / cellulose gel is prepared by dissolution, co-precipitation, hydrothermal synthesis and freeze-drying particles. Since the present invention skillfully uses the ZnCl2 aqueous solution as the solvent of the cellulose and the zinc source of the nano-ZnO, there is no need to add other cellulose solvents, and the preparation process is clean and environment-friendly. In addition, after the cellulose is dissolved, the hydroxyl groups on its molecules combine with zinc ions, which effectively promotes the formation of nano-ZnO, and the hydrothermal synthesis temperature is correspondingly significantly reduced. Therefore, the preparation process has the advantage of energy saving.

Owner:NANJING FORESTRY UNIV

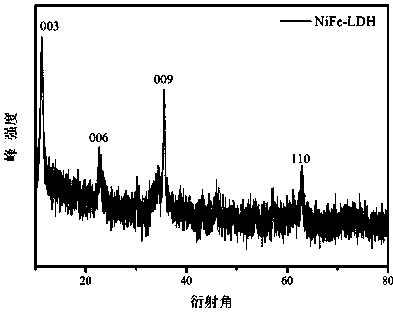

A preparation method and application of a metal lithium negative electrode composite copper foil current collector loaded with layered bimetallic hydroxide

ActiveCN109004233AImprove mechanical propertiesGood chemical stabilityElectrode carriers/collectorsDissolutionCopper foil

The invention discloses a method for preparing a metal lithium negative electrode composite copper foil current collector loaded with layered bimetallic hydroxide, which comprises the following steps:(1) weighing nickel nitrate hexahydrate, iron nitrate nonahydrate and urea, and adding deionized water for ultrasonic dissolution; (2) packaging the cut copper foil on a glass plate with adhesive tape, exposing only one side of the copper foil, and then wiping with absolute ethanol; (3) transferring the ultrasonic dissolved solution to the polytetrafluoroethylene liner, placing the copper foil into the liner, placing the liner into the stainless steel reaction kettle shell, and reacting in an oven; 4) take out that reaction kettle, cooling to room temperature, take out the copper foil, cleaning with deionized wat and absolute ethanol, and drying at room temperature. The NiFe powder prepared by the solvothermal method is characterized in that the NiFe powder prepared by the solvothermal method is characterized in that the NiFe powder prepared by the solvothermal method is characterized in that: LDH has good mechanical properties. The array structure formed on the surface of copper foilcan increase the specific surface area of the electrode, which is conducive to the contact between the electrode surface and the electrolyte and to obtain uniform lithium ion flux.

Owner:HARBIN INST OF TECH

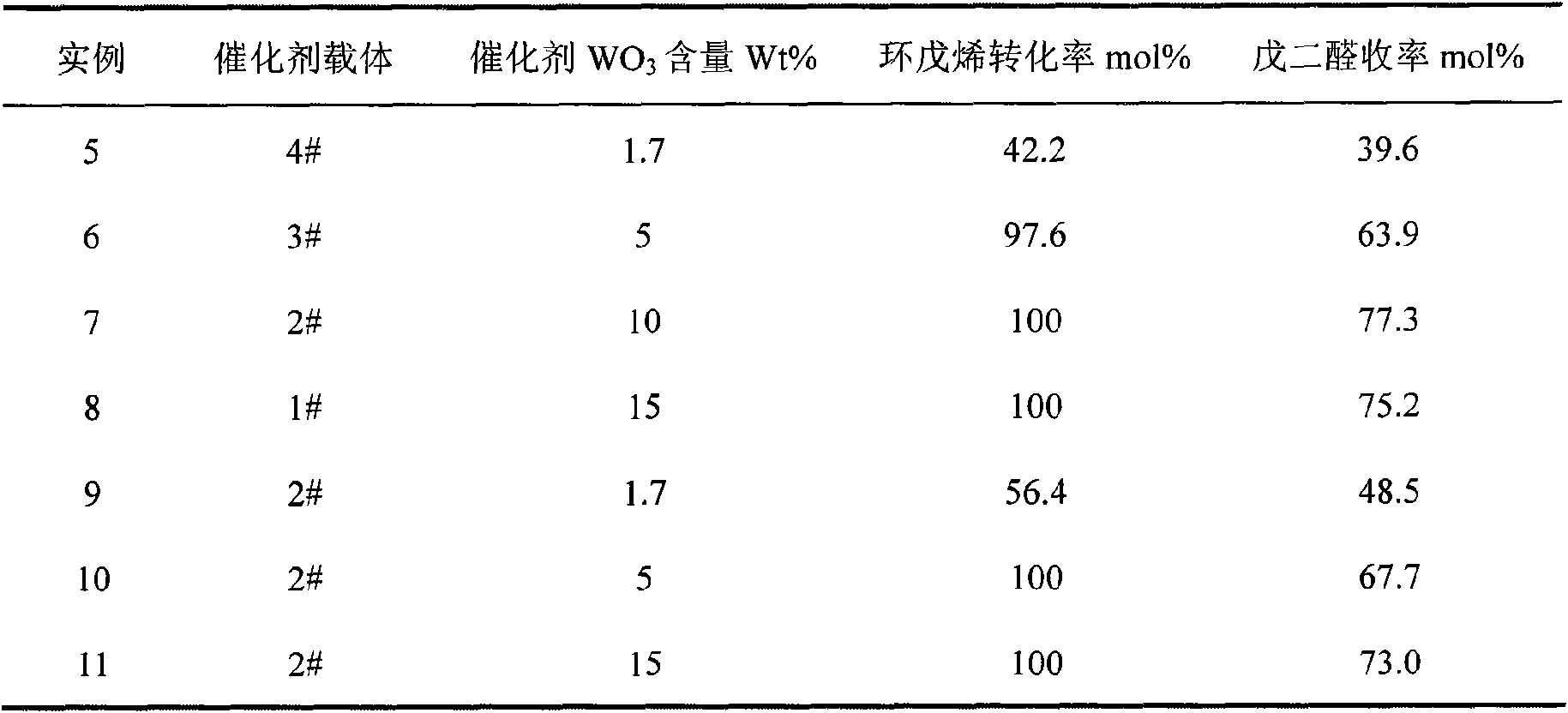

Catalyst for oxidizing-synthesizing glutaric dialdehyde with cyclopentene and preparation method thereof

InactiveCN101564686AHigh activityGood choiceCatalyst activation/preparationCarbonyl compound preparation by oxidationCyclopenteneMolecular sieve

The invention discloses a catalyst for oxidizing-synthesizing glutaric dialdehyde with cyclopentene and a preparation method thereof. The catalyst adopts a Ti-MSU type mesoporous molecular sieve as a carrier and is a supported catalyst supporting tungstic oxide on surface; the carrier Ti-MSU type mesoporous molecular sieve has a three-dimensional vertical-crossing arrangement vermiform pore canal structure, bigger aperture and higher specific surface; and the mol ratio of silicon to titanium is 1:0.01 to 1:0.04; and the content of tungstic oxide adopted as the active component accounts for 1 to 15 percent of the mass of the catalyst. The catalyst has the characteristics of high activation, better selectivity, mild reaction condition for catalyst preparation and glutaric dialdehyde synthesis with the catalyst, low cost, long service life, better industrial application prospect and environment-friendly property in the whole process from catalyst preparation to glutaric dialdehyde synthesis.

Owner:GUANGDONG UNIV OF TECH

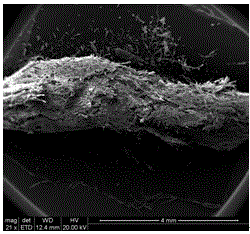

Preparation method and application of highly dispersed modified lignin

The invention relates to the technical field of organic chemicals, in particular to preparation of highly dispersed modified lignin for functional modification of rubber materials, and also relates toan application of the highly dispersed modified lignin. The lignin used is a papermaking pulping black liquid, pretreatment is not needed, processing links are reduced, and energy consumption is reduced. An alkoxy donor is added for hydroxymethylation modification on the black liquid, and polarity of a phenolic hydroxyl group is reduced; long chain fatty acid is added, the lignin is coated and isolated by polarity attraction, mutual adhesion between lignin particles is reduced, the dispersion performance of the modified lignin product is improved, part of carboxylic acid groups are esterifiedwith hydroxymethyl by stirring and heating after spray drying, and the surface polarity of the lignin is further reduced.

Owner:江西宝弘纳米科技有限公司

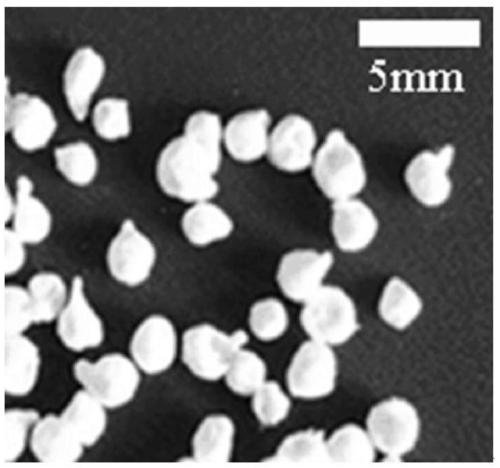

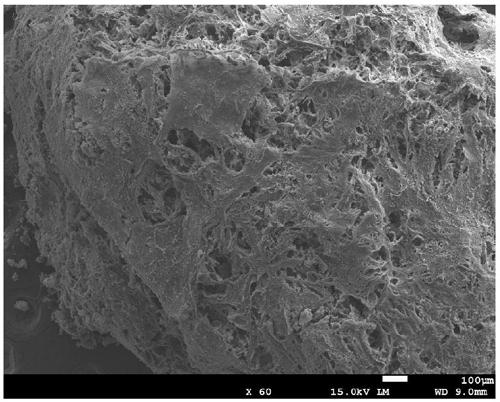

Regenerated cellulose pellet containing sheet nanometer ZnO inside and preparing method thereof

ActiveCN108993605AImprove the shortcomings of difficult recyclingPromote high-value utilizationWater/sewage treatment by irradiationWater treatment compoundsPolymer scienceFreeze-drying

A regenerated cellulose pellet containing sheet nanometer ZnO inside and a preparing method thereof are disclosed. In the regenerated cellulose pellet that is a novel material, the thickness of ZnO nanosheets is 20-50 nm, and the diameter of the regenerated cellulose pellet is 2-4 mm. The method includes subjecting dissolved cellulose fibers, as a raw material, to low-temperature pretreatment, dissolving, injection for pellet formation, in-situ synthesis and freeze-drying to prepare the regenerated cellulose pellet containing sheet nanometer ZnO inside, with an aqueous ZnCl2 solution being adopted as a solvent for the cellulose and a zinc source of nanometer ZnO. The material is easy to recover and high in practicability.

Owner:NANJING FORESTRY UNIV

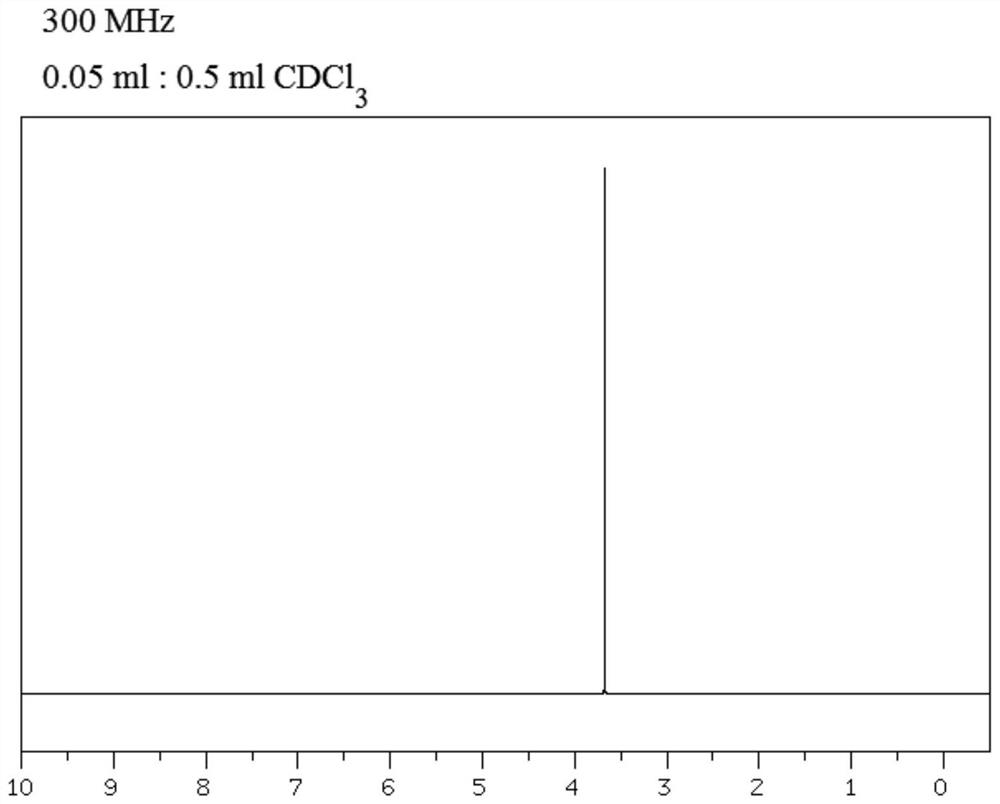

Cyclic silicate ester compound used in battery electrolyte and preparation method thereof

ActiveCN109053792AImprove performanceHigh reversible specific capacityGroup 4/14 element organic compoundsSecondary cellsChemical compoundBattery electrolyte

The invention relates to a cyclic silicate ester compound used in battery electrolyte and a preparation method thereof, and belongs to the technical field of the battery electrolyte. A structure of the compound is as shown in a formula as follows: (with reference to the specification), wherein n is greater than or equal to 2, R1 and R2 are selected from C1 to C8 linear alkyl or branched alkyl, andwhen n is equal to 2 or 3, R1 and R2 are not methyl at the same time. The invention simultaneously further provides the cyclic silicate ester compound used in the battery electrolyte and the preparation method thereof. When the cyclic silicate ester compound prepared in the invention is added into the battery electrolyte, performance of the battery can be obviously improved. The preparation method disclosed by the invention is simple to operate and mild and stable in preparation process. By control of the process disclosed by the invention, synthesis time of preparing the cyclic silicate ester compound is greatly reduced.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

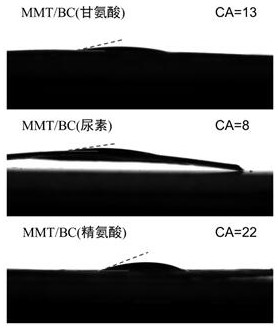

Preparation method of bacterial cellulose-based aqueous zinc ion battery diaphragm material

ActiveCN113270686ASave raw materialsNo pollution in the processSecondary cellsCell component detailsFreeze-dryingElectrical battery

The invention discloses a preparation method of a bacterial cellulose-based aqueous zinc ion battery diaphragm material, and the method comprises the following steps of 1, adding montmorillonite into deionized water, and mechanically stirring and uniformly dispersing; adding a small molecule substance into the mixture solution, stirring at room temperature, and stripping the montmorillonite to obtain a suspension containing the sliced montmorillonite; 2, carrying out centrifugal separation on the suspension, washing with deionized water for multiple times, and centrifuging to obtain a sliced montmorillonite solid precipitate; 3, carrying out freeze drying on the sliced montmorillonite solid precipitate to obtain the sliced montmorillonite powder; 4, uniformly dispersing the sliced montmorillonite powder and the bacterial cellulose homogenate in the deionized water to obtain a homogeneous suspension; and 5, filtering the homogeneous suspension to obtain a wet diaphragm, and carrying out vacuum drying to obtain an MMT / BC diaphragm. The prepared MMT / BC diaphragm has the properties of high porosity, excellent mechanical strength, high liquid retention capacity and the like, and the electrochemical performance of a zinc negative electrode in an aqueous zinc ion battery can be improved.

Owner:HARBIN INST OF TECH

A kind of preparation method of highly dispersed modified lignin and application thereof

The invention relates to the technical field of organic chemical industry, in particular to the preparation of highly dispersed modified lignin for functional modification of rubber materials, and also to its application. The lignin used is the black liquor of papermaking pulping, no pretreatment is required, the processing links are reduced, and the energy consumption is reduced. The black liquor is modified by methylolation by adding alkoxyl donors, reducing the polarity of phenolic hydroxyl groups, and then adding long chain Fatty acids can coat and isolate lignin through polar attraction, reduce the mutual adhesion between lignin particles, and improve the dispersion performance of modified lignin products. After spray drying, stir and heat to make some carboxylic acid groups and hydroxyl groups The esterification of the methyl group further reduces the surface polarity of the lignin.

Owner:江西宝弘纳米科技有限公司

Synthesis method of trimethoxyboroxine

ActiveCN109053789AHigh yieldHigh purityGroup 3/13 element organic compoundsSecondary cells servicing/maintenanceSynthesis methodsAcid value

The invention provides a synthesis method of trimethoxyboroxine. Borane methyl sulfide serves as a raw material to react with carbon dioxide, trimethoxyboroxine is obtained, borane methyl sulfide is added into a Schlenk reaction bottle at the temperature of -60 - -80 DEG C, THF (tetrahydrofuran) is added into the Schlenk reaction bottle to be mixed for 15-20 seconds under the pressure of 0.5-0.7Pa, carbon dioxide is guided into the reaction bottle, the pressure is controlled to be 90-100kPa, then heating is conducted till the temperature reaches 70-80 DEG C, it is detected that no borane methyl sulfide exists, the reaction is ended, and trimethoxyboroxine is obtained. The preparation method is simple, the preparation technology is clean and environmentally friendly, the preparation processis moderate and stable, the yield of the prepared trimethoxyboroxine is high, the purity is high, the water content is low, and the acid value is low.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

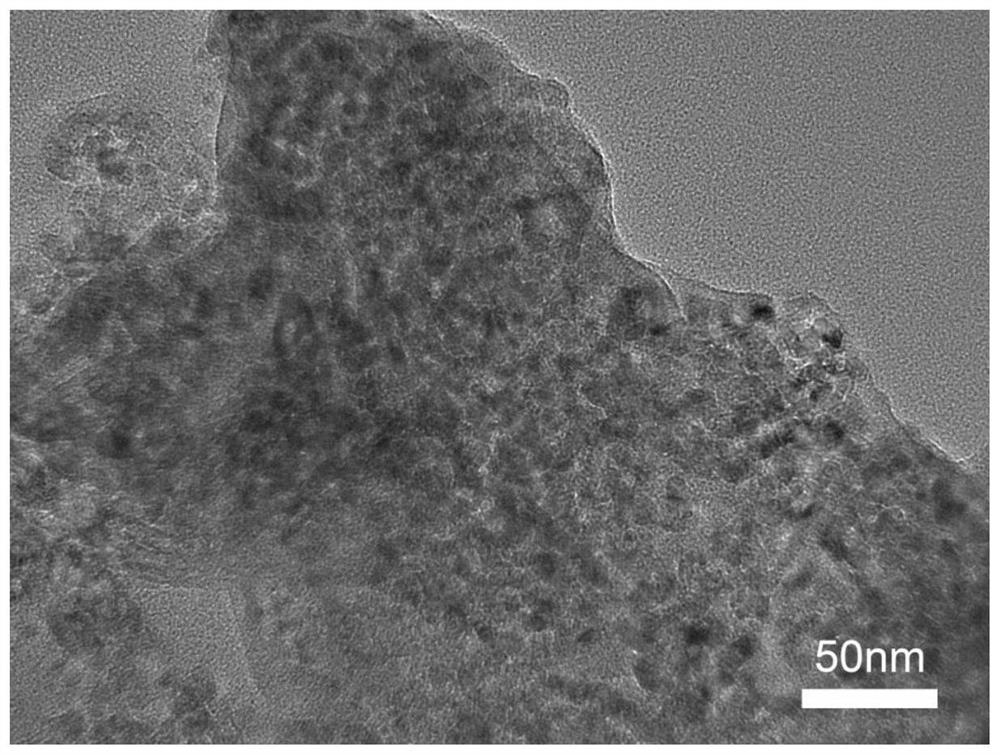

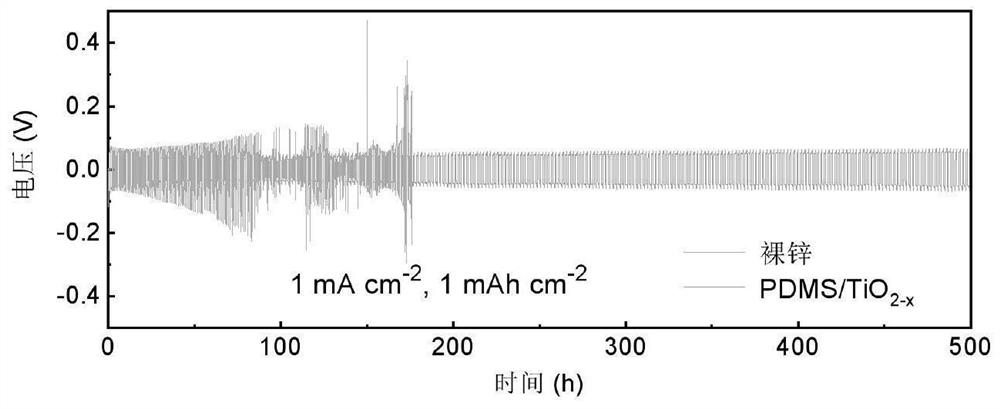

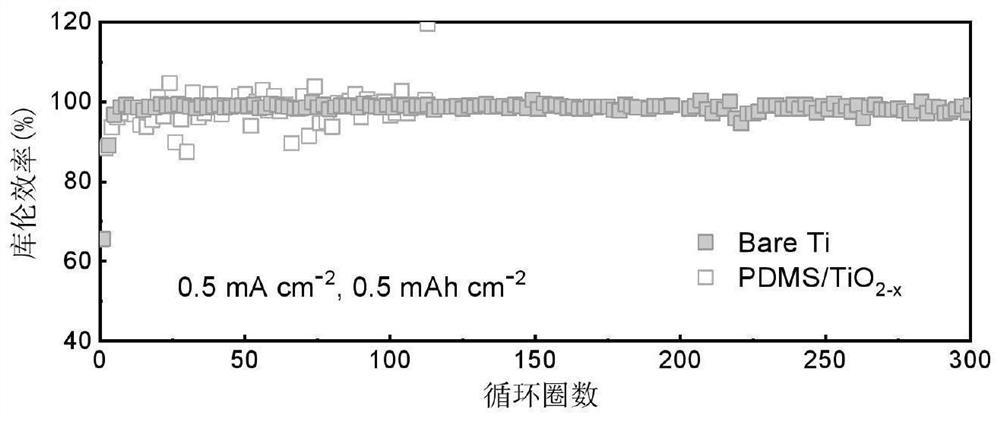

Preparation method and application of in-situ rapid growth multifunctional zinc negative electrode protective layer

ActiveCN113363410BEliminate surface defects of negative electrodeUniform depositionElectrode manufacturing processesSecondary cellsElectrical batteryZinc metal

The invention discloses a preparation method and application of a multifunctional zinc negative electrode protective layer rapidly grown in situ. The method comprises the following steps: 1. preparing a surface modification solution A; 2. preparing a surface modification solution B; 3. preparing a surface modification solution B; Surface modification solution A is slowly poured into surface modification solution B under stirring; 4. Prepare rust removal solution; 5. Soak the zinc metal pole piece in the rust removal solution in step 4; 6. Seal the zinc obtained in step 5 One side of the pole piece; 7. Soak the zinc pole piece obtained in step 6 into the modification solution in step 3 to obtain a zinc negative electrode with a modification layer. In the present invention, an interfacial layer tightly combined with the zinc substrate is formed in situ on the surface of the zinc metal negative electrode by the chemical deposition method. The modified layer has uniform thickness and uniform distribution, which can effectively eliminate the surface defects of the zinc negative electrode, guide the uniform deposition of zinc ions, and suppress dendrites. growth, and hinder the precipitation of hydrogen, which is conducive to the stable cycle of the zinc anode, thereby improving the electrochemical performance and cycle life of the battery.

Owner:HARBIN INST OF TECH

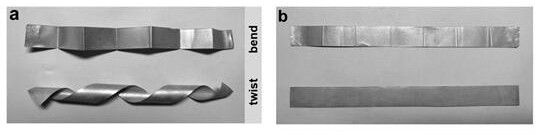

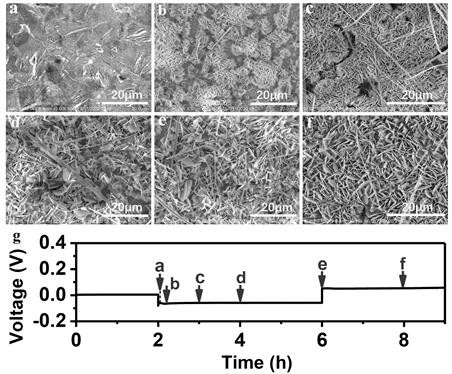

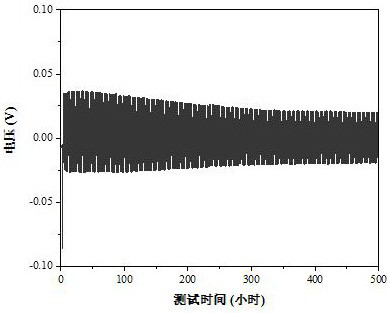

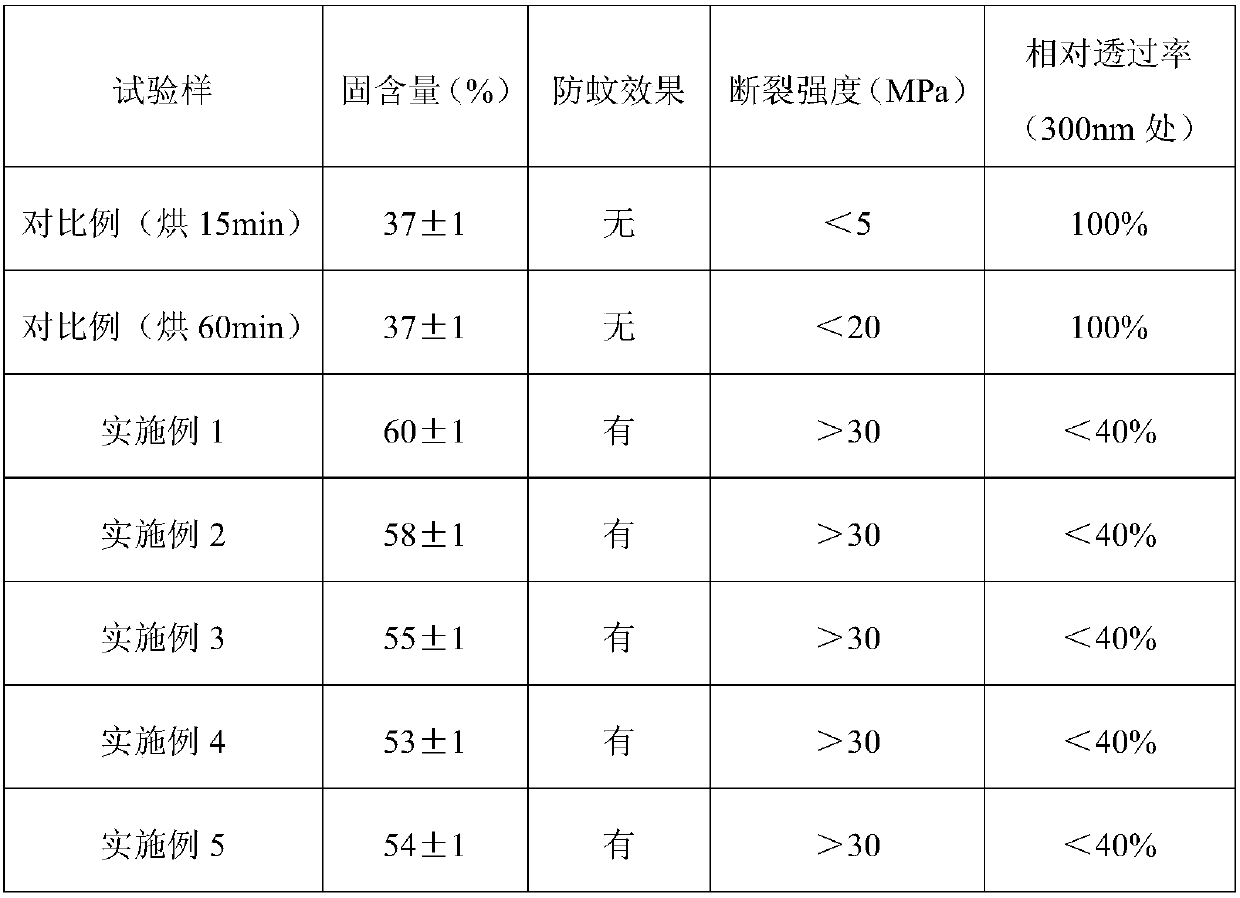

Light-cured polyurethane acrylate emulsion containing mosquito-repellent plant extract and applied to spinning coating

PendingCN109679065AHigh solid contentSmall molecular weightAntifouling/underwater paintsPaints with biocidesWater dispersibleSide chain

The invention discloses a light-cured polyurethane acrylate emulsion containing a mosquito-repellent plant extract and applied to a spinning coating. The light-cured polyurethane acrylate emulsion isprepared with a method comprising steps as follows: dimethylolbutanoic acid, diols containing non-ionic hydrophilic groups in side chains and diols with molecular weight of 1000-2000 are subjected tomelt mixing, after vacuum dewatering is performed, diisocyanate is added, a mixture is subjected to a reaction at 80-100 DEG C, and a polyurethane prepolymer (a) is prepared; a light-cured end-cappingagent with residual NCO mole number of 40%-70% and containing active functional groups and carbon-carbon double bonds is added to the prepolymer (a), cooling is performed after the reaction, a salt-forming agent is added for a neutralization reaction, and a water-dispersible polyurethane acrylate prepolymer (b) is obtained; the prepolymer (b) is added to an insect-repellent plant extracting solution and mixed uniformly, then a mixed solution is dispersed in deionized water, a nano dispersion and a coupling agent are added for continuous stirring reaction, and therefore, the light-cured polyurethane acrylate emulsion containing the mosquito-repellent plant extract and applied to the spinning coating is obtained and has the characteristics of high solid content, short curing time, stable mosquito-repellent function, ultraviolet resistance and aging resistance.

Owner:四川省纤维检验局

A kind of preparation method and application of zinc ion battery metal zinc negative electrode dynamic interface coating

ActiveCN113540390BGrowth inhibitionImprove ionic conductivitySecondary cellsElectrode collector coatingElectrical batteryZinc ion

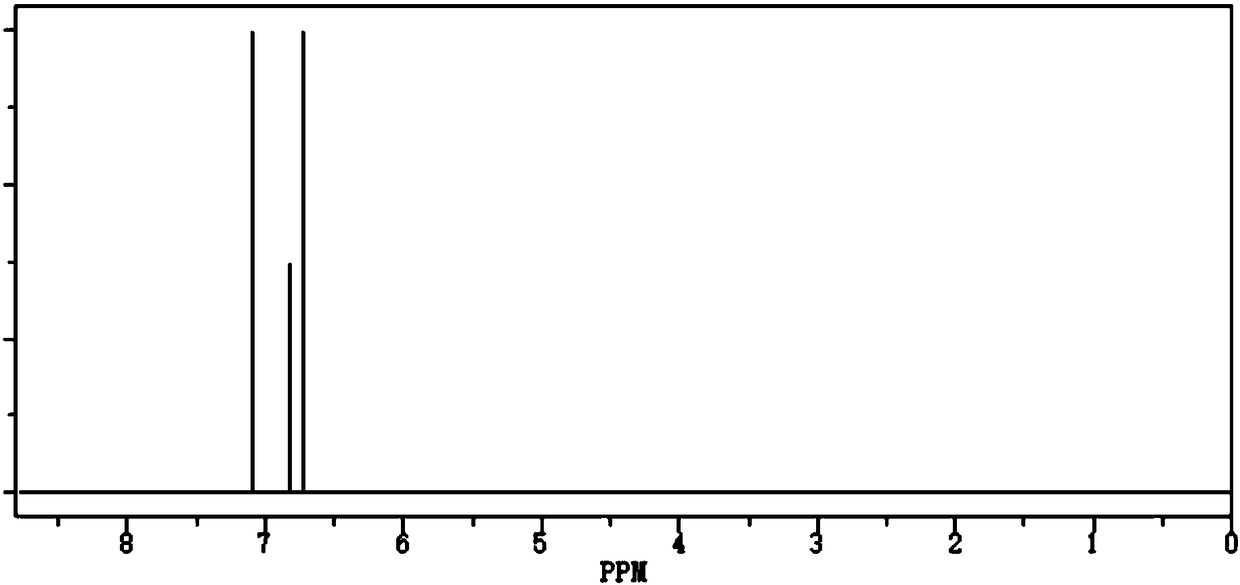

The invention discloses a preparation method and application of a dynamic interface coating for a metal zinc negative electrode of a zinc ion battery, belonging to the technical field of energy materials. In the present invention, an interface layer that dynamically adapts to interfacial volume changes is modified on the surface of the metal zinc negative electrode of the zinc ion battery by a spin coating method, and the synthesized polymer PDMS has extremely high viscoelastic properties and exhibits high dynamic adaptability. Prepared TiO 2‑x Contains abundant oxygen vacancies. The dynamic interface coating prepared above can be applied in aqueous zinc-ion batteries. The present invention prepares PDMS / TiO with dynamic self-adaptive volume change 2‑x Interfacial coating, dynamic buffer volume changes suppress dendrite growth while inducing Zn via abundant oxygen vacancies 2+ The rapid and uniform transfer further improves the ionic conductivity of the interfacial layer to stabilize the Zn metal surface, thereby enhancing the utilization and cycle life of the battery.

Owner:HARBIN INST OF TECH

Synthetic method of triphenoxyboroxine

InactiveCN108586510AHigh yieldHigh puritySecondary cellsGroup 3/13 element organic compoundsBorane dimethylsulfideAcid value

A synthetic method of triphenoxyboroxine belongs to the technical field of battery electrolyte and includes: subjecting borane-dimethylsulfide complex as a raw material to reaction with phenol to obtain triphenoxyboroxine, adding borane-dimethylsulfide complex into a Schlenk reaction flask, adding THF (tetrahydrofuran), mixing, adding phenol and water into the mixture, heating to allow reacting under 70-80 DEG C and 1-5 atm for 1-1.5 h, allowing reacting under 70-80 DEG C and 8-120 Pa for 30-40 min, allowing reacting under 3-5 Pa and 80-100 DEG C for 20-30 min, concentrating and drying, and cooling to room temperature to obtain triphenoxyboroxine. The synthetic method has the advantages that preparation is simple, a preparation technique is good in cleanliness and environmental friendliness, the preparation process is mild and stable, and prepared triphenoxyboroxine has high yield, high purity, low water content and low acid value.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

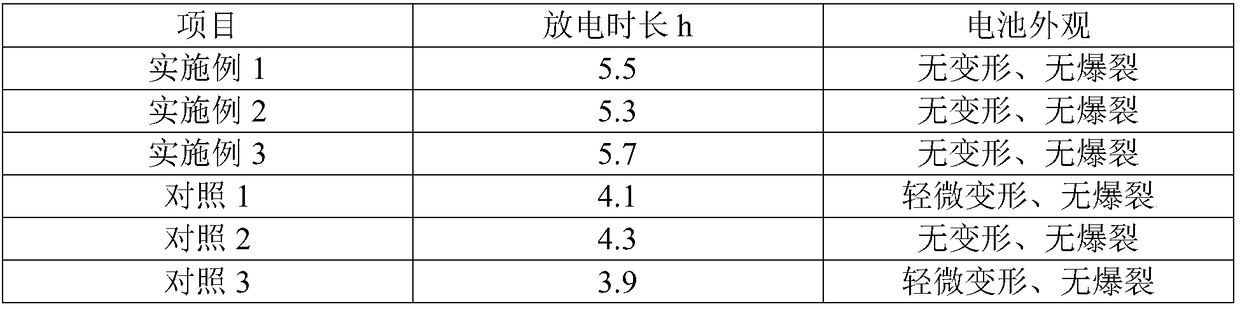

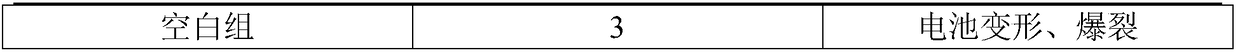

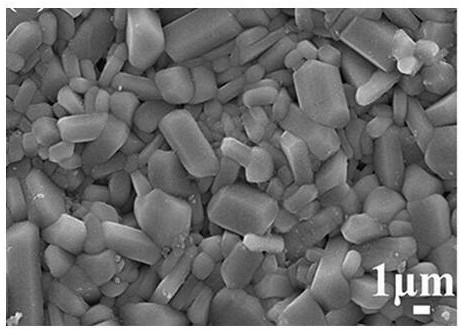

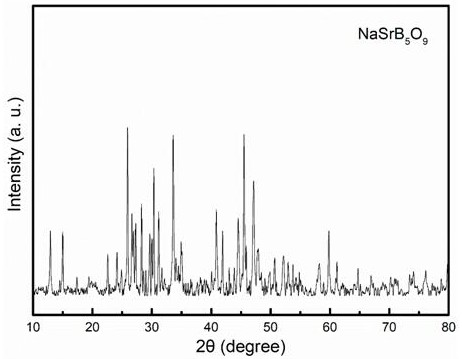

Low dielectric and low loss boride LTCC material and preparation method thereof

ActiveCN114180939AThe preparation process is clean and environmentally friendlyPreparation method is stableLow-k dielectricMicrowave signals

The invention discloses a low dielectric and low loss boride LTCC material and a preparation method thereof, the chemical expression of the boride LTCC material is ABB5O9, in the formula, A is Li or Na; b is Sr, Ba or Ca. The preparation process of the boride LTCC material sequentially comprises the following steps: preparing ABB5O9 powder by a hydrothermal method, carrying out ball milling, carrying out compression molding, and sintering to form ceramic. The main crystal phase of the prepared ABB5O9-based LTCC material is ABB5O9 (A = Li and Na, and B = Sr, Ba and Ca) single phase, and the ABB5O9-based LTCC material has the advantages of low raw material cost, low sintering temperature (700-825 DEG C), low dielectric constant (4.3-8.5), high Qf value (10500-58850 GHz), simple preparation process, good reproducibility and the like, can solve the time delay problem of microwave signals in high-frequency communication, improves the stability of microwave signal transmission, and is very suitable for being used as an LTCC microwave substrate.

Owner:NANJING INST OF TECH

The synthetic method of trimethoxyboroxane

ActiveCN109053789BHigh yieldHigh purityGroup 3/13 element organic compoundsSecondary cells servicing/maintenanceMethyl sulfideMethyl palmoxirate

The invention provides a synthesis method of trimethoxyboroxine. Borane methyl sulfide serves as a raw material to react with carbon dioxide, trimethoxyboroxine is obtained, borane methyl sulfide is added into a Schlenk reaction bottle at the temperature of -60 - -80 DEG C, THF (tetrahydrofuran) is added into the Schlenk reaction bottle to be mixed for 15-20 seconds under the pressure of 0.5-0.7Pa, carbon dioxide is guided into the reaction bottle, the pressure is controlled to be 90-100kPa, then heating is conducted till the temperature reaches 70-80 DEG C, it is detected that no borane methyl sulfide exists, the reaction is ended, and trimethoxyboroxine is obtained. The preparation method is simple, the preparation technology is clean and environmentally friendly, the preparation processis moderate and stable, the yield of the prepared trimethoxyboroxine is high, the purity is high, the water content is low, and the acid value is low.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Porous ion conduction membrane with gradient distribution of pore diameters, and preparation method and application thereof

ActiveCN112652797AHigh selectivityImprove ionic conductivityRegenerative fuel cellsOrganic polymerMaterials science

The invention discloses an application of a porous ion conduction membrane with gradient distribution of pore diameters in an alkaline zinc-iron flow battery. The membrane is prepared by blending organic polymer resin and inorganic particles capable of reacting with acid to generate gas and then carrying out phase inversion in an acid solution. In the membrane forming process, a membrane casting solution solvent exchanges with a non-solvent to form a pore structure, and meanwhile, protonic acid in the non-solvent reacts with inorganic particles in the membrane casting solution to generate gas after entering the membrane casting solution, so that a porous ion conduction membrane with pore diameters in gradient distribution is generated in the membrane forming process. The porous ion conduction membrane with gradient distribution of pore diameters is simple in process, environment-friendly in process and controllable in pore diameter and porosity, and batch production is easy to realize. Compared with an original porous membrane, the porous ion conduction membrane with gradient distribution of pore diameters can control the pore structure by controlling the content of inorganic particles and the concentration of acid in a non-solvent, so that the flow battery assembled by the porous ion conduction membrane has good battery performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A porous ion-conducting membrane with gradient distribution of pore size and its preparation and application

ActiveCN112652797BHigh selectivityImprove ionic conductivityRegenerative fuel cellsNon solventInorganic particle

The invention discloses the application of a porous ion-conducting membrane with a gradient distribution of pore diameters in an alkaline zinc-iron liquid flow battery. This type of film is prepared by blending organic polymer resin and inorganic particles that can react with acid to generate gas, and then undergo phase inversion in acid solution. During the film forming process, the solvent of the casting solution is exchanged with the non-solvent to form a pore structure. At the same time, after the protonic acid in the non-solvent enters the casting solution, it reacts with the inorganic particles in the casting solution to generate gas, so that the The process produces a porous ion-conducting membrane with a gradient distribution of pore sizes. This kind of porous ion-conducting membrane with gradient distribution of pore diameter has a simple process, environmentally friendly process, controllable pore diameter and porosity, and is easy to realize mass production. Compared with the original porous membrane, this kind of porous ion-conducting membrane with gradient distribution of pore size can control the pore structure by controlling the content of inorganic particles and the concentration of acid in the non-solvent, and the assembled flow battery has good battery performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method and application of carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with heterojunction structure

ActiveCN107768620BGood adsorption capacity of lithium polysulfideImprove stabilityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesHeterojunctionTin dioxide

The invention relates to a preparation method and application of a carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with a heterojunction structure, and belongs to the technical field of an energy material. The method comprises the following steps: 1, dissolving tin tetrachloride, thioacetamide and carbon nanofiber into polypropyl alcohol and performing hydrothermal reaction to obtain a carbon nanofiber, tin disulfide and tin dioxide composite material with the heterojunction structure; 2, dipping the composite material obtained in the step 1 into a sulfur solution, taking out after 5 minutes, vacuum-drying and calcining at high temperature to obtain the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure. The preparation method and the application of the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with the heterojunction structure have the following advantages: the composite material has special interface effect, can effectively increase electrode surface electron and ion transmission speed and is favorable for realize efficient utilization of the sulfur and obtainingthe cyclic stable lithium sulfur battery. The composite material can be prepared by directly utilizing a one-step hydrothermal method, the preparation method is simple and practical, and the components are controllable.

Owner:HARBIN INST OF TECH

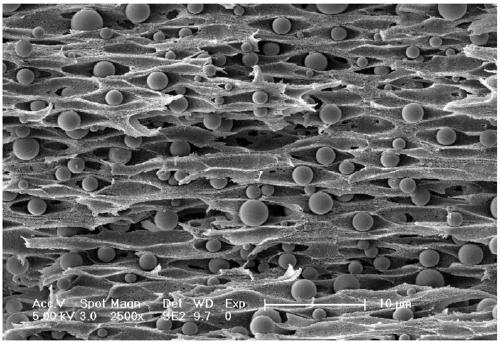

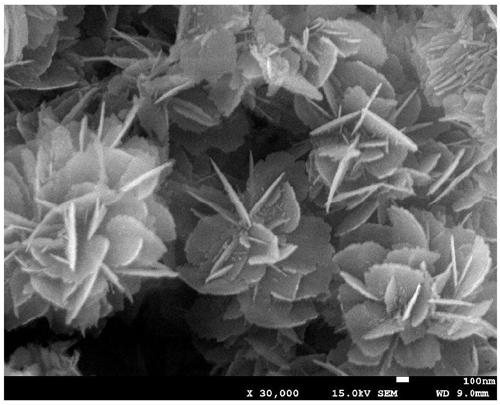

Regenerated cellulose microsphere containing flower-like nanometer ZnO and preparation method thereof

ActiveCN108889339AImprove the shortcomings of difficult recyclingPromote high-value utilizationWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionMicrosphere

The invention discloses a regenerated cellulose microsphere containing flower-like nanometer ZnO and a preparation method thereof. According to the novel regenerated cellulose microsphere, the thickness of petaline nanometer ZnO is 100-200 nm, and the diameter of the regenerated cellulose microsphere is 2-4 mm. According to the preparation method, a ZnCl2 water solution is adopted as a solvent forcellulose and a zinc source of nanometer ZnO, and dissolving pulp cellulose fibers are adopted as the raw materials of cellulose and subjected to low-temperature pretreatment, dissolution, injectioninto a ball shape, in-situ synthesis and freeze drying to prepare the regenerated cellulose microsphere containing flower-like nanometer ZnO. A preparation process is clean, environmentally friendly and capable of saving energy; through in-situ synthesis, the regenerated cellulose microsphere containing flower-like nanometer ZnO is prepared without a hydrothermal reaction or heating, flower-like nanometer ZnO is mainly distributed in the regenerated cellulose microsphere and cannot shed, and the regenerated cellulose microsphere has wide application in light-catalyzed reactions.

Owner:NANJING FORESTRY UNIV

Cyclic silicate compound used in battery electrolyte and preparation method thereof

ActiveCN109053792BImprove performanceHigh reversible specific capacityGroup 4/14 element organic compoundsSecondary cellsElectrolytic agentPhysical chemistry

The cyclic silicate compound used in the battery electrolyte and its preparation method belong to the technical field of the battery electrolyte, and the structure of the compound is shown in the following formula: wherein n≥2, R 1 , R 2 Selected from C1-C8 straight chain alkyl or branched chain alkyl, when n=2 or 3, R 1 , R 2 Not simultaneously methyl. The present invention also provides a cyclic silicate compound used in the battery electrolyte and a preparation method thereof. Adding the cyclic silicate compound prepared in the present invention to the battery electrolyte can significantly improve the performance of the battery. The present invention The preparation method is simple in operation, the preparation process is mild and stable, and the synthesis time for preparing the cyclic silicate compound is greatly shortened through the process control of the invention.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

A kind of preparation method and application of graphene composite metal boride and sulfur composite nanomaterial

ActiveCN107742706BGood adsorption capacity of lithium polysulfideImprove stabilityCell electrodesLithium sulfurMaterials science

The invention relates to a preparation method and application of a graphene composite metal boride and sulfur composite nano material and belongs to the technical field of energy materials. The preparation method comprises the following steps: dissolving a reducing agent and NaOH in deionized water under inert gas protection conditions, dissolving metal salt in deionized water and separately placing obtained two solutions in ice-water baths; slowly adding a metal salt aqueous solution into a reducing agent solution under inert gas protection conditions, stirring for 30 minutes and calcining for 2-10 hours at a high temperature to obtain metal boride; then performing a hydrothermal reaction on grapheme and the metal boride to obtain graphene compound metal boride; and mixing the graphene compound metal boride with elemental sulfur, and heating and calcining for 12-24 hours at a temperature of 150-180 DEG C to obtain the graphene composite metal boride and sulfur composite nano material.The preparation method and the application of the graphene composite metal boride and sulfur composite nano material, provided by the invention, have the advantages that the graphene compound metal boride has very high lithium polysulfide adsorption capacity, and the stability of a lithium-sulfur battery can be improved; and the cost of preparation raw materials is low, the preparation process issimple, and the preparation process is clean and environmentally-friendly.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com