Cyclic silicate compound used in battery electrolyte and preparation method thereof

A technology of electrolyte and silicate, which is applied in the fields of compounds of group 4/14 elements of the periodic table, chemical instruments and methods, and secondary batteries, etc. Long working hours and other problems, to achieve the effect of increasing reversible specific capacity, high purity and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

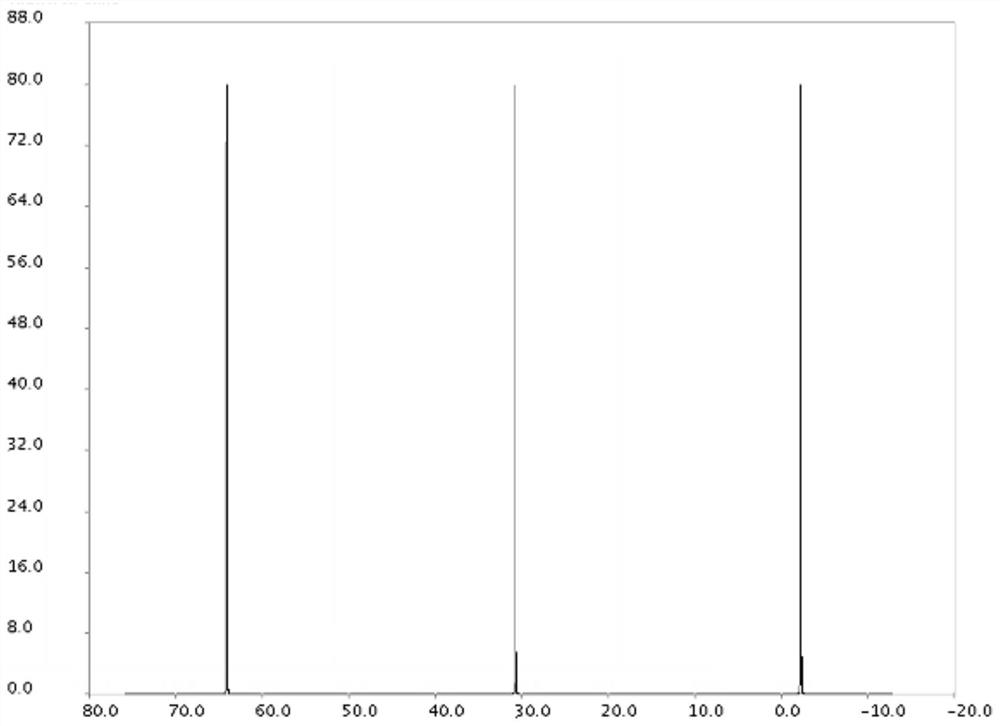

[0029] Dimethyl silicate-1,4-butanediol, the structural formula is as follows:

[0030]

[0031] The above-mentioned 1,4-butanediol dimethyl silicate is prepared from 1,4-butanediol and dimethyldichlorosilane as follows, including the following steps: adding 1.1 mol of 1,4- Dissolve butanediol in ethylene dichloride, then add 1mol dimethyldichlorosilane dropwise at 23°C, control the temperature during the dropwise addition to not exceed 35°C, and add dimethyldichlorosilane by volume The ratio 1:2:3 is divided into three parts, and then the three times of dripping time are controlled to be 8min, 10min, and 12min in sequence. After the dropping is completed (the detection temperature is 30°C), firstly, heat at a heating rate of 1°C / min for 10min. Then heat at a heating rate of 5°C / min for 19 minutes, then heat at a heating rate of 0.5°C / min for 10 minutes, and then heat up to 140°C, and then perform a heat preservation reaction (by timing, the heat preservation reaction only ...

Embodiment 2

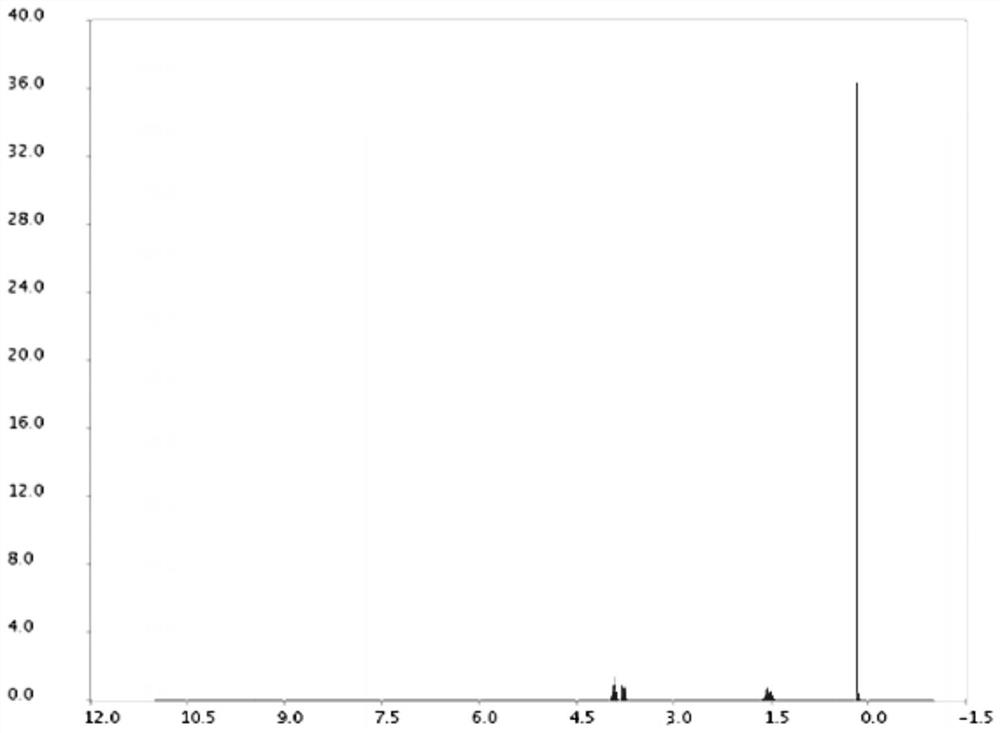

[0034] 1,5-pentanediol dimethyl silicate, the structural formula is as follows:

[0035]

[0036] The above-mentioned 1,5-pentanediol dimethyl silicate is prepared from 1,5-pentanediol and dimethyldichlorosilane as follows, including the following steps: adding 1.3 mol of 1,5- Pentylene glycol was dissolved in ethylene glycol dimethyl ether, and then 1mol dimethyldichlorosilane was added dropwise at 27°C. During the dropping process, the temperature was controlled not to exceed 35°C. According to the volume ratio of 1:2:3, it is divided into three parts, and then the three times of dropping time are controlled to be 8min, 10min, and 12min. 15min, then heated at a heating rate of 5°C / min for 18.4min, then heated at a heating rate of 1°C / min for 10min, raised to 150°C, and then carried out a heat preservation reaction (by timing, the heat preservation reaction only needs 1.5h). Then add N,N-dimethylaniline, adjust the pH value to 6, stir for 25 minutes, suction filter while ...

Embodiment 3

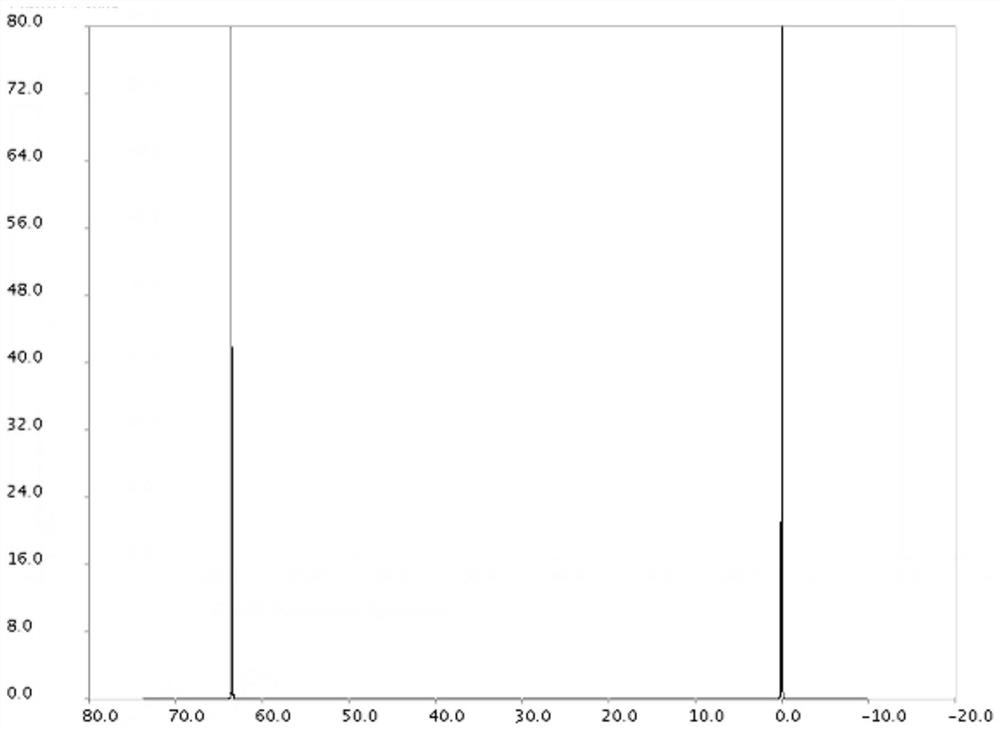

[0039] Ethylene glycol diethyl silicate, the structural formula is as follows:

[0040]

[0041] The above-mentioned ethylene glycol diethyl silicate is prepared from ethylene glycol and diethyldichlorosilane as follows, including the following steps: dissolving 1.2 mol of ethylene glycol in toluene, and then at 25°C Add 1 mol of diethyldichlorosilane dropwise, and control the temperature during the dropping process to not exceed 35°C. During the dropwise addition, divide diethyldichlorosilane into three parts according to the volume ratio of 1:2:3, and then control the three times of dropping Adding time is 8min, 10min, 12min in turn. After the dropwise addition is completed (detection temperature is 32°C), first heat at a heating rate of 0.5°C / min for 10min, then heat at a heating rate of 3°C / min for 15min, and then heat at a heating rate of 0.5°C Heating at a heating rate of 1 / min for 5 minutes, raising the temperature to 84.5°C, and then performing a heat preservation r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com