Preparation method and application of in-situ rapid growth multifunctional zinc negative electrode protective layer

A zinc negative electrode and multifunctional technology, which is applied in the field of preparation of multifunctional zinc negative electrode protective layer, can solve the problems of dendrite growth, hydrogen evolution problem, poor negative electrode stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

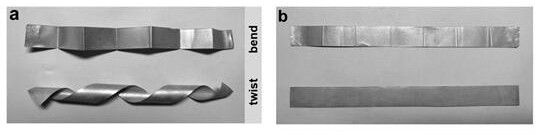

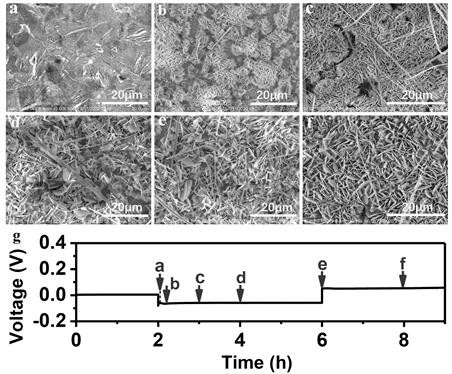

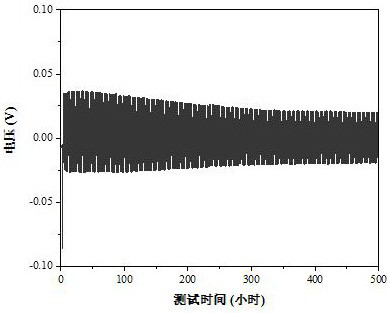

Embodiment 1

[0028] Dissolve 0.4g of sodium molybdate into 40mL of deionized water, and at the same time dissolve 0.2g (65wt%) of nitric acid and 0.1g of sodium dodecylbenzenesulfonate into 15mL of deionized water under stirring conditions. Slowly pour the sodium molybdate solution into the above acidic solution, add sodium bicarbonate to adjust the pH to 2, and heat to 40°C in a water bath with stirring. In addition, a 20wt% aqueous solution of sulfuric acid was prepared and the zinc pole piece was immersed in it for acid treatment for 10 seconds, and then it was taken out and cleaned. Cut a suitable size of scotch tape and seal one side of the pole piece. After making the above preparations, put the pole piece into the zinc molybdate treatment solution for 20 seconds, then take it out quickly, clean it with deionized water, and place it in a ventilated environment to dry naturally. After cutting the above-mentioned modified zinc pole piece to a suitable size, a symmetrical battery is as...

Embodiment 2

[0032] Dissolve 0.6g of sodium titanate in 40mL of ethanol, and dissolve 0.2g (≥85wt%) of phosphoric acid and 0.1g of lauric acid in 20mL of ethanol while stirring. Slowly pour the sodium titanate solution into the above acidic solution, add potassium hydrogen phthalate to adjust the pH value to 4, and heat to 30° C. in a water bath while stirring. In addition, a 15wt% dilute hydrochloric acid aqueous solution was prepared, and the zinc pole piece was immersed in it for acid treatment for 20 seconds, and then it was taken out and cleaned. Cut a suitable size of scotch tape and seal one side of the pole piece. After making the above preparations, put the pole piece into the zinc molybdate treatment solution for 40 seconds, then take it out quickly, clean it with deionized water, and place it in a ventilated environment to dry naturally. After cutting the above-mentioned modified zinc pole piece to a suitable size, a symmetrical battery is assembled. The electrolyte is 3M ZnSO...

Embodiment 3

[0035] Dissolve 0.4g of sodium silicate into 30mL of deionized water, and at the same time dissolve 2g (30wt%) of hydrogen peroxide and 0.1g of sodium cetyl sulfate into 10mL of deionized water under stirring conditions. Slowly pour the sodium silicate solution into the above acidic solution, add potassium dihydrogen phosphate to adjust the pH to 3 and heat to 50°C in a water bath with stirring. In addition, prepare 10wt% dilute nitric acid aqueous solution and immerse the zinc pole piece in it for acid treatment for 15s, then take it out and clean it. Cut a suitable size of scotch tape and seal one side of the pole piece. After making the above preparations, put the pole piece into the zinc molybdate treatment solution for 2 minutes, then take it out quickly, clean it with deionized water, and place it in a ventilated environment to dry naturally. After cutting the above-mentioned modified zinc pole piece to a suitable size, a symmetrical battery is assembled. The electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com