Nanometer microcrystalline cellulose reinforcing polylactic acid glycolic acid electrospun membrane, preparation method thereof and application

A polylactic acid glycolic acid electrospinning film, polylactic acid glycolic acid technology, applied in the field of biomedicine, can solve problems such as co-spun film without polylactic acid glycolic acid and cellulose, achieve clean and environmentally friendly preparation process, make up for limitations, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

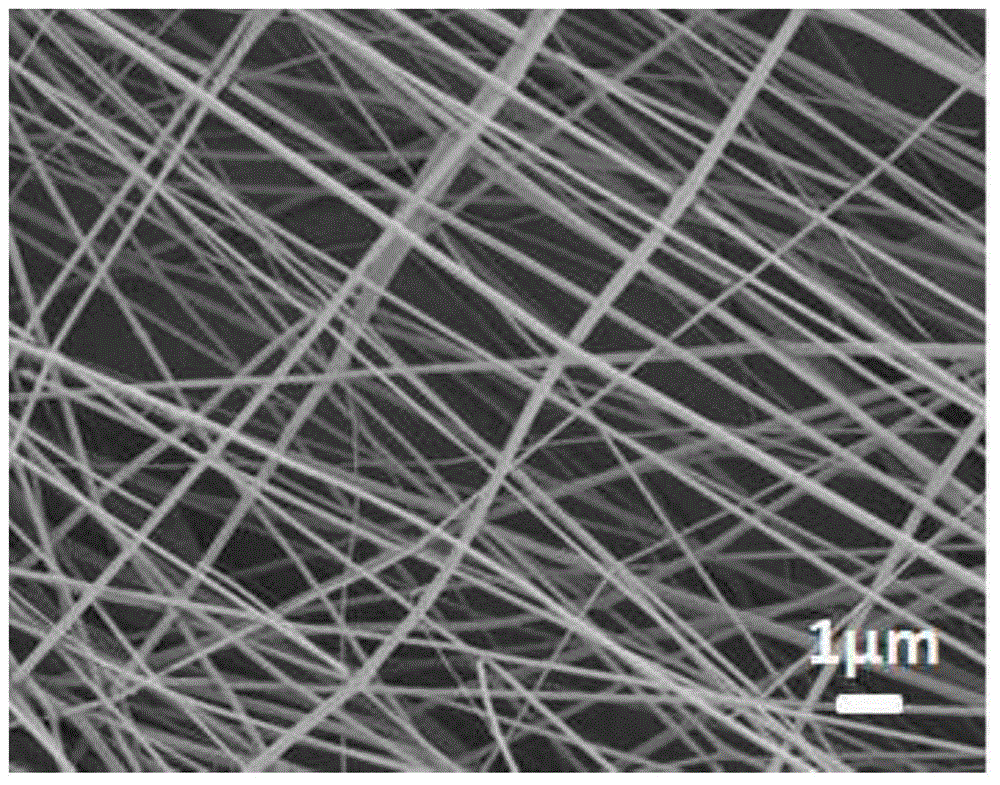

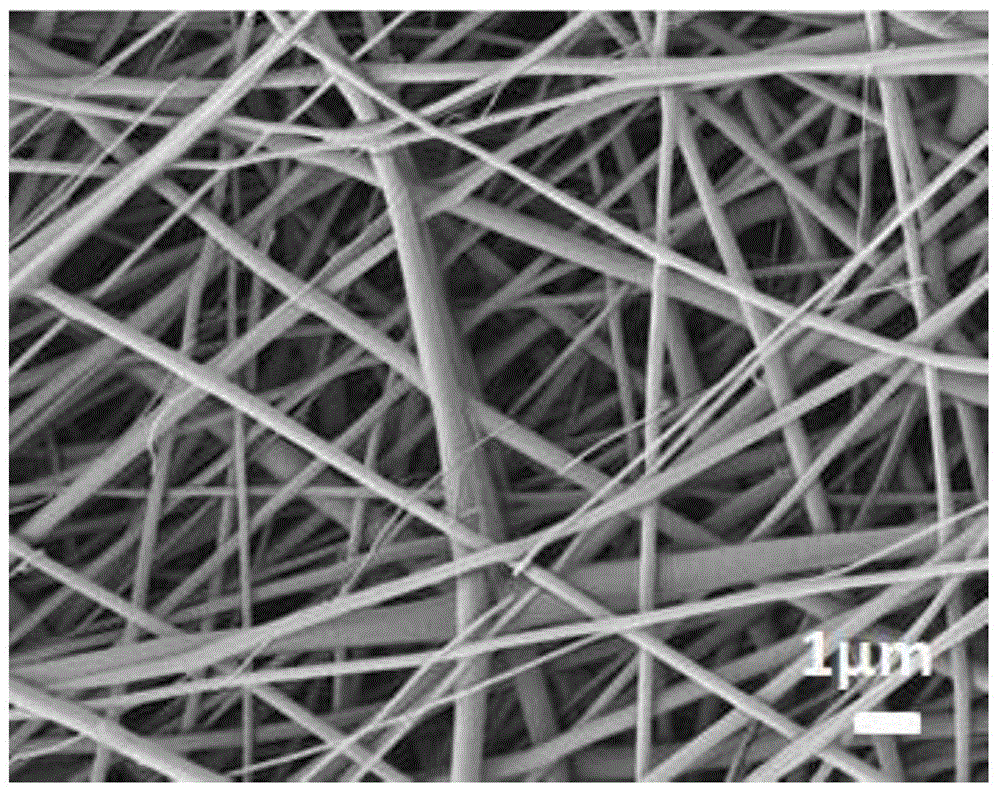

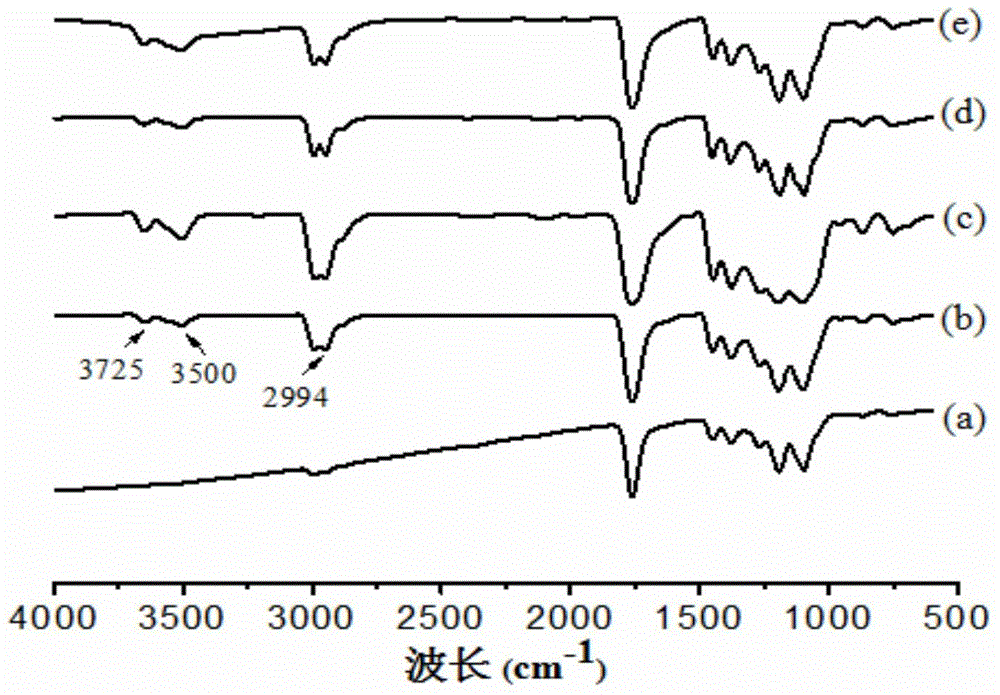

Image

Examples

Embodiment 2

[0043] (1) Preparation of nanocrystalline cellulose

[0044] Weigh 15g of microcrystalline cellulose powder, add it to 140mL of 65wt% concentrated sulfuric acid, and mechanically stir it in a water bath at 40°C for 6 hours. Ultrasonic dispersion, followed by repeated dialysis with water three times until the pH value is stable, the dialyzed sample was placed in a refrigerator at 4°C overnight, and then freeze-dried at -60°C to obtain white nanocrystalline cellulose.

[0045] (2) Preparation of polylactic-glycolic acid (PLGA) solution

[0046] Draw 5mL of hexafluoroisopropanol solution and pour it into a container containing 0.75g of polylactic-glycolic acid (PLGA, LA / GA=75 / 25, Mv=5000), quickly close the bottle cap, and place it on a magnetic stirrer Stir until the polylactic glycolic acid (PLGA) in the container is completely dissolved, and the solution is transparent and clear;

[0047] (3) Preparation of electrostatic spinning emulsion dispersion

[0048] Add 0.0225g nan...

Embodiment 3

[0052] (1) Preparation of nanocrystalline cellulose

[0053] Weigh 15g of microcrystalline cellulose powder, add it to 140mL of 65wt% concentrated sulfuric acid, and mechanically stir it in a water bath at 40°C for 6 hours. Ultrasonic dispersion, followed by repeated dialysis with water three times until the pH value is stable, the dialyzed sample was placed in a refrigerator at 4°C overnight, and then freeze-dried at -60°C to obtain white nanocrystalline cellulose.

[0054] (2) Preparation of polylactic-glycolic acid (PLGA) solution

[0055] Draw 5mL of hexafluoroisopropanol solution and pour it into a container containing 1.0g of polylactic-glycolic acid (PLGA, LA / GA=75 / 25, Mv=5000), quickly close the bottle cap, and place it on a magnetic stirrer Stir until the polylactic glycolic acid (PLGA) in the container is completely dissolved, and the solution is transparent and clear;

[0056] (3) Preparation of electrostatic spinning emulsion dispersion

[0057] Add 0.05g of nan...

Embodiment 4

[0061] (1) Preparation of nanocrystalline cellulose

[0062] Weigh 15g of microcrystalline cellulose powder, add it to 140mL of 65wt% concentrated sulfuric acid, and mechanically stir it in a water bath at 40°C for 6 hours. Ultrasonic dispersion, followed by repeated dialysis with water three times until the pH value is stable, the dialyzed sample was placed in a refrigerator at 4°C overnight, and then freeze-dried at -60°C to obtain white nanocrystalline cellulose.

[0063] (2) Preparation of polylactic-glycolic acid (PLGA) solution

[0064] Draw 5 mL of hexafluoroisopropanol solution and pour it into a container containing 1.25 g of polylactic-glycolic acid (PLGA, LA / GA=75 / 25, Mv=5000), quickly close the bottle cap, and place it on a magnetic stirrer Stir until the polylactic glycolic acid (PLGA) in the container is completely dissolved, and the solution is transparent and clear;

[0065] (3) Preparation of electrostatic spinning emulsion dispersion

[0066] Add 0.0875g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com