Preparation method for strip-type nano ZnO/cellulose gel material

A cellulose gel, cellulose technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high temperature of nano-ZnO, environmental pollution, unfavorable spinning into fiber or film forming process, etc. To achieve the effect of reducing the temperature of hydrothermal synthesis, cleaning and environmental protection of the preparation process, and promoting the formation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

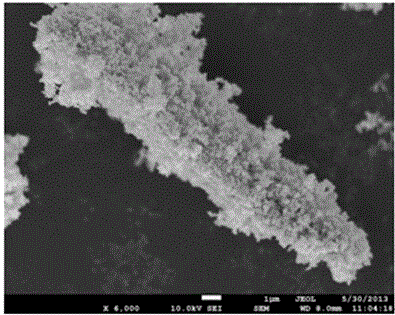

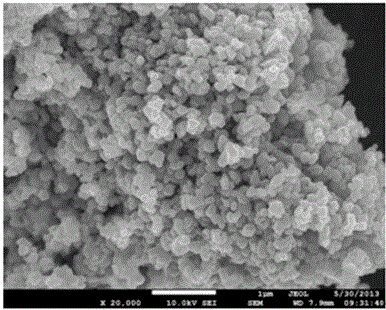

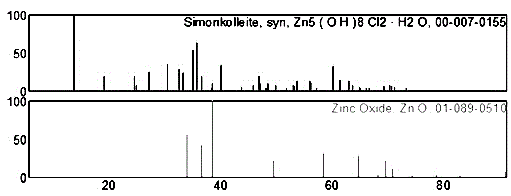

Embodiment 1

[0028] Add 1 g of wood pulp cellulose fibers to 65% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at 10°C for 1 h. The above liquid-solid material was placed in a water bath at 70° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 Slowly inject 20% NaOH aqueous solution into the aqueous solution, adjust the pH value of the system to 9, and let it stand for 24 hours to obtain a strip-shaped ZnO precursor / cellulose gel. The strip ZnO precursor / cellulose gel was put into a hydrothermal synthesis kettle, and the hydrothermal reaction was carried out under the conditions of pH = 9 and temperature 120 ° C, and the reaction time was 6 h. Wash strips of ZnO / cellulose gel to be free of Cl - Finally, put it in an ultra-low temperature refrigerator. After freezing, place the sample in a freeze dryer. After drying, a new strip-shaped nano-ZnO / cellulose gel material is obtained. ...

Embodiment 2

[0034] Add 1 g of bamboo pulp cellulose fibers to 68% (wt%) ZnCl 2 In the aqueous solution, pretreat for 3 hours in a low-temperature bath at -10°C. The above liquid-solid material was placed in a water bath at 60° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 The aqueous solution was slowly injected into a 15% NaOH aqueous solution, and when the pH value of the system was adjusted to 7, it was left to stand for 48 hours to obtain a strip-shaped ZnO precursor / cellulose gel. The strip-shaped ZnO precursor / cellulose gel was put into a hydrothermal synthesis kettle, and the hydrothermal reaction was carried out under the conditions of pH=7 and temperature of 170°C, and the reaction time was 4h. Wash strips of ZnO / cellulose gel to be free of Cl - Finally, put it in an ultra-low temperature refrigerator. After freezing, place the sample in a freeze dryer. After drying, a new strip-shaped nano-Z...

Embodiment 3

[0037] Add 1 g of cotton pulp cellulose fibers to 70% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at 30°C for 0.5h. The above liquid-solid material was placed in a water bath at 90° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2The aqueous solution was slowly injected into a 30% NaOH aqueous solution, and when the pH value of the system was adjusted to 10, it was left to stand for 36 hours to obtain a strip-shaped ZnO precursor / cellulose gel. The strip-shaped ZnO precursor / cellulose gel was put into a hydrothermal synthesis kettle, and the hydrothermal reaction was carried out under the conditions of pH=10 and temperature 100 °C, and the reaction time was 10 h. Wash strips of ZnO / cellulose gel to be free of Cl - Finally, put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new strip-shaped nano-Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com