Regenerated cellulose microsphere containing flower-like nanometer ZnO and preparation method thereof

A technology for regenerating cellulose and cellulose, applied in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc. The preparation process is clean and environmentally friendly, improving high-value utilization, and improving the effect of difficult recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

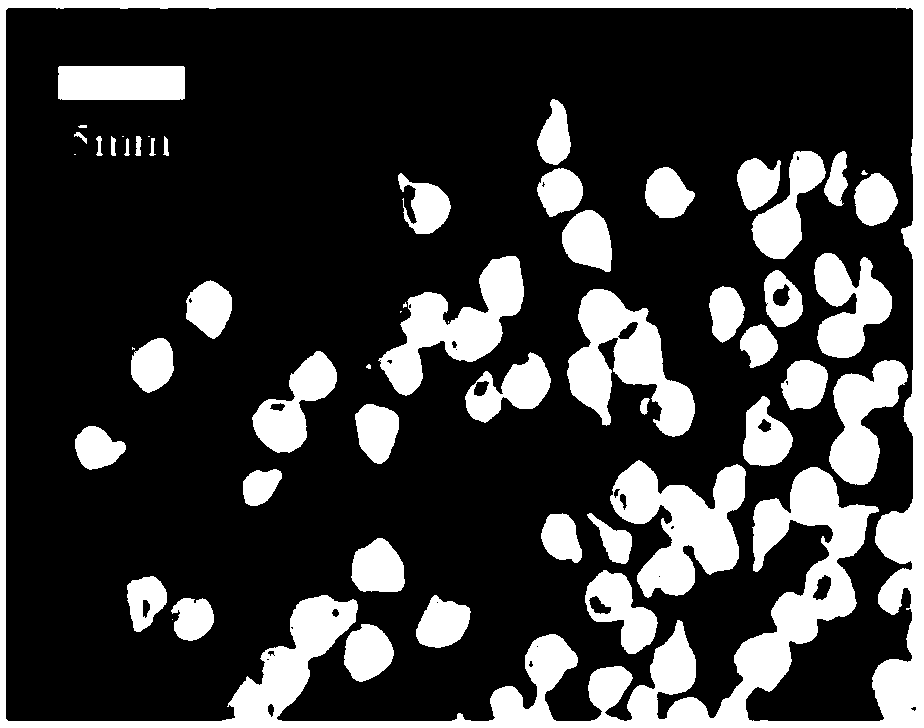

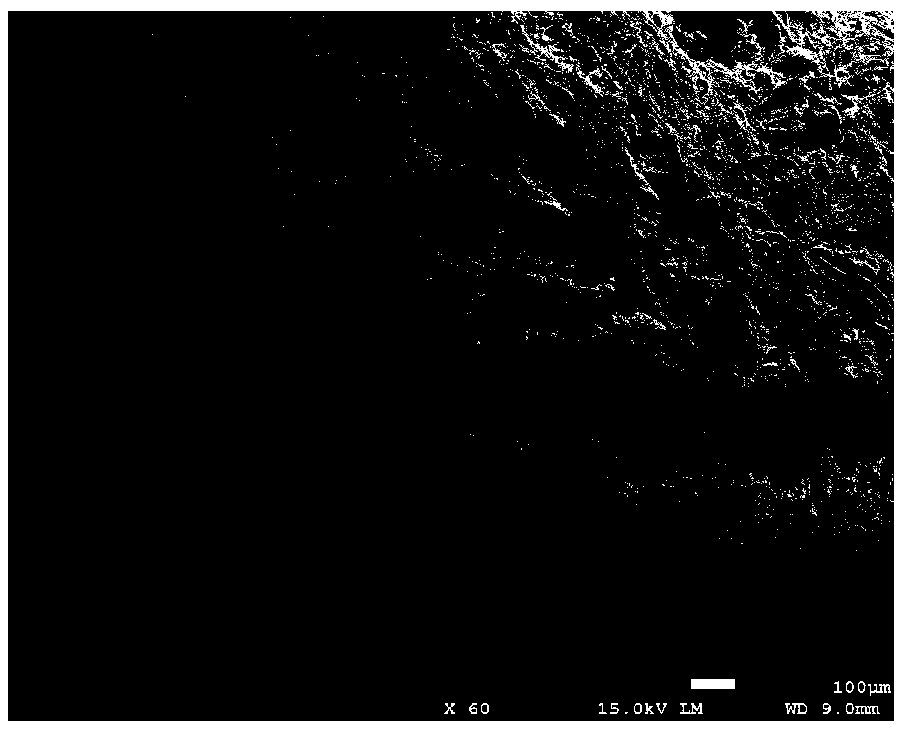

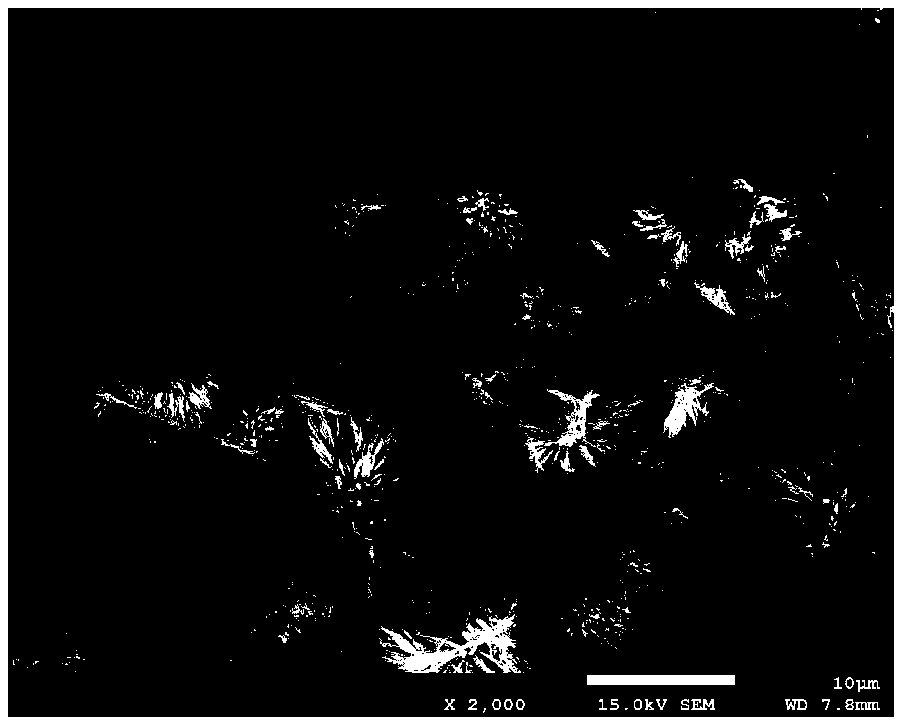

[0027] 2g of wood pulp cellulose fibers were added to 100g of 70% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at 0°C for 3 hours. The above liquid-solid material was placed in a water bath at 70° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 The aqueous solution was injected into a 50% NaOH aqueous solution in the form of pellets, and allowed to stand for 12 hours. Filter the pellet and wash the pellet with distilled water until Cl-free - , put it into an ultra-low temperature refrigerator, and put the sample in a freeze dryer after freezing. After drying, a new material of regenerated cellulose pellets containing flower-like nano-ZnO was obtained. The characterization results are as follows Figure 1~6 shown. Depend on figure 1 It can be seen that the diameter of the pellets is 2-4 mm. Depend on figure 2 It can be seen that the surface of the pellet is ne...

Embodiment 2

[0029] 2g of wood pulp cellulose fibers were added to 60g of 65% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at -10°C for 4 hours. The above liquid-solid material was placed in a water bath at 70° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 The aqueous solution was injected into a 50% NaOH aqueous solution in the form of pellets, and allowed to stand for 14 hours. Filter the pellet and wash the pellet with distilled water until Cl-free - , put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new material of regenerated cellulose pellets containing flower-shaped nano ZnO is obtained. The diameter of the ball is 2-4mm, and the thickness of the petal is about 100-200nm.

Embodiment 3

[0031] 2g of cotton pulp cellulose fibers were added to 120g of 65% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at -10°C for 4 hours. The above liquid-solid material was placed in a water bath at 80° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 The aqueous solution was injected into a 50% NaOH aqueous solution in the form of pellets and allowed to stand for 16 hours. Filter the pellet and wash the pellet with distilled water until Cl-free - , put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new material of regenerated cellulose pellets containing flower-shaped nano ZnO is obtained. The diameter of the ball is 2-4mm, and the thickness of the petal is about 100-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com