Regenerated cellulose pellet containing sheet nanometer ZnO inside and preparing method thereof

A technology of regenerated cellulose and cellulose, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve the problems of limited application, high density of inorganic carriers, poor environmental friendliness, etc., and achieve The preparation process is clean and environmentally friendly, improving high-value utilization and improving the effect of difficult recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

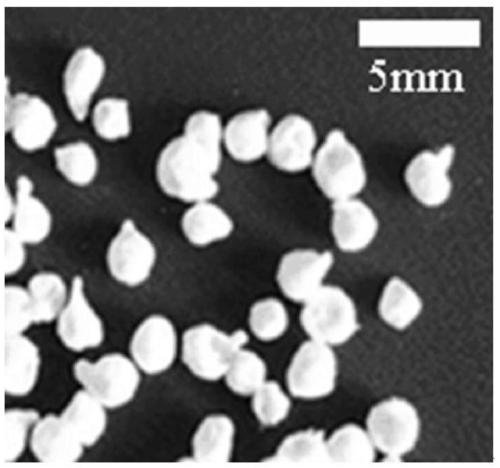

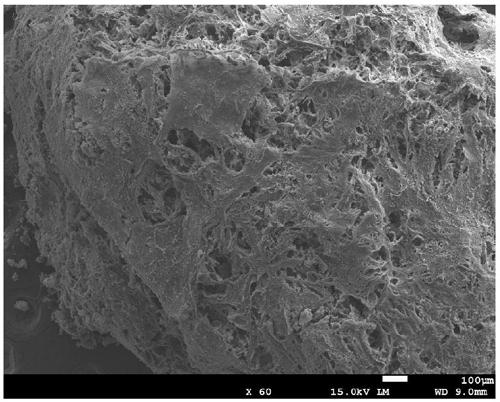

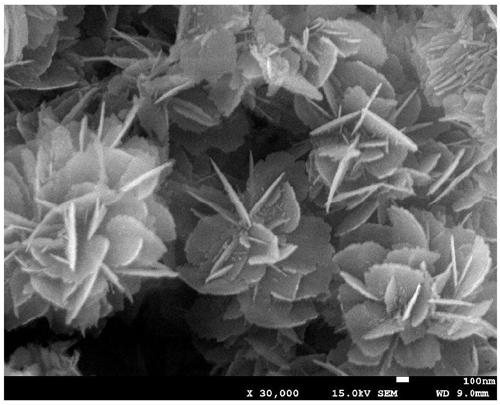

[0027] 2g of wood pulp cellulose fibers were added to 100g of 65% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at 0°C for 3 hours. The above liquid-solid material was placed in a water bath at 60° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 The aqueous solution was injected into a 50% NaOH aqueous solution in the form of pellets, and left to stand for 24 hours. Filter the pellet and wash the pellet with distilled water to be free of C1 - , put it in an ultra-low temperature refrigerator, and put the sample in a freeze dryer after freezing. After drying, a new material of regenerated cellulose pellets containing flaky nano-ZnO was obtained. The characterization results are as follows Figure 1-5 shown. Depend on figure 1 It can be seen that the diameter of the pellets is 2-4 mm. Depend on figure 2 It can be seen that the surface of the pellet is network-li...

Embodiment 2

[0029] 2g of wood pulp cellulose fibers were added to 80g of 65% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at -10°C for 4 hours. The above liquid-solid material was placed in a water bath at 70° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 The aqueous solution was injected into a 50% NaOH aqueous solution in the form of pellets, and left to stand for 26 hours. Filter the pellet and wash the pellet with distilled water until Cl-free - , put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new material of regenerated cellulose pellets containing flaky nano ZnO is obtained. The diameter of the small ball is 2-4mm, and the thickness of the ZnO nanosheet is about 20-50nm.

Embodiment 3

[0031] 2g bamboo pulp cellulose fiber is added to the ZnCl of 60g 70% (wt%) 2 In aqueous solution, pretreatment in a low-temperature bath at 20°C for 4 hours. The above liquid-solid material was placed in a water bath at 60° C. and heated and stirred to obtain a transparent and uniform cellulose solution. Use a syringe to dissolve the ZnCl of cellulose 2 The aqueous solution was injected into a 50% NaOH aqueous solution in the form of pellets, and allowed to stand for 18 hours. Filter the pellet and wash the pellet with distilled water until Cl-free - , put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new material of regenerated cellulose pellets containing flaky nano ZnO is obtained. The diameter of the small ball is 2-4mm, and the thickness of the ZnO nanosheet is about 20-50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com