Preparation method and application of nanometer LiF/Fe/graphite positive electrode lithium supplementing slurry

A cathode and graphite technology, applied in the field of energy materials, can solve problems such as low coulomb efficiency for the first time, and achieve the effects of simple production process, low cost, and clean and environmentally friendly preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Mix 7 g LiF, 5 g Fe powder, and 1 g graphite evenly;

[0023] (2) Add 20 ml of absolute ethanol to the evenly mixed powder, stir evenly and transfer the slurry to a high-energy ball mill tank for high-energy ball milling for 2 h;

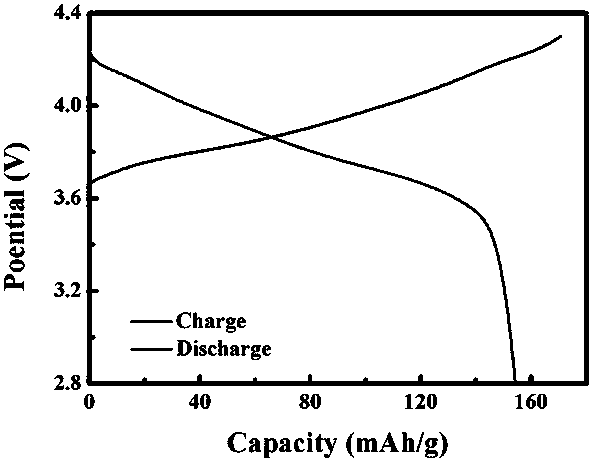

[0024] (3) Add LiFPO dropwise to the nano-LiF / Fe / graphite positive electrode lithium supplement slurry obtained after ball milling 4 The surface of the positive electrode sheet (mass fraction is about 5%) is coated with a coater with a thickness of 5 µm, and can be used as a lithium-ion battery positive electrode after drying at 100 °C.

Embodiment 2

[0026] (1) Mix 7 g LiF, 5 g Fe powder, and 1 g graphite evenly;

[0027] (2) Add 20 ml of absolute ethanol to the evenly mixed powder, stir evenly and transfer the slurry to a high-energy ball mill tank for high-energy ball milling for 4 h;

[0028] (3) Add LiFPO dropwise to the nano-LiF / Fe / graphite positive electrode lithium supplement slurry obtained after ball milling 4 The surface of the positive electrode sheet (mass fraction is about 5%) is coated with a coater with a thickness of 5 µm, and can be used as a lithium-ion battery positive electrode after drying at 100 °C.

Embodiment 3

[0030] (1) Mix 7 g LiF, 5 g Fe powder, and 1 g graphite evenly;

[0031] (2) Add 20 ml of absolute ethanol to the evenly mixed powder, stir evenly and transfer the slurry to a high-energy ball mill tank for high-energy ball milling for 8 h;

[0032] (3) Add LiFPO dropwise to the nano-LiF / Fe / graphite positive electrode lithium supplement slurry obtained after ball milling 4 The surface of the positive electrode sheet (mass fraction is about 5%) is coated with a coater with a thickness of 5 µm, and can be used as a lithium-ion battery positive electrode after drying at 100 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com