Preparation method of bacterial cellulose-based aqueous zinc ion battery diaphragm material

A bacterial cellulose and zinc-ion battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problem of damaging the low-cost advantages of zinc-ion batteries, not enough to maintain structural integrity, and easy to pierce the glass fiber diaphragm and other problems, to achieve excellent water holding capacity, cheap production raw materials, clean and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

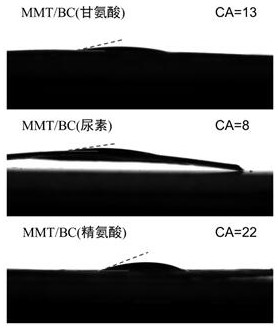

[0022] (1) Weigh 500 mg of montmorillonite and add it to 40 mL of deionized water, stir mechanically for 10 min to disperse the montmorillonite evenly; then add 300 mg of arginine to it, stir magnetically at room temperature for 7 days, and The soil is fully stripped to obtain a suspension containing sheet-layer montmorillonite;

[0023] (2) Centrifuge the mixed suspension containing lamella montmorillonite at 4000 rpm / min, wash and centrifuge with deionized water several times to obtain a solid precipitate of lamella montmorillonite;

[0024] (3) Freeze-drying the sheet-layer montmorillonite to obtain sheet-layer montmorillonite powder;

[0025] (4) Weigh 10 mg of lamella montmorillonite and 1.5 g of bacterial cellulose homogenate with a mass concentration of 2 wt%, and disperse them evenly in deionized water to obtain a homogeneous suspension of the two;

[0026] (5) The homogeneous suspension was vacuum filtered to obtain the MMT / BC wet film; the MMT / BC wet film was vacuum...

Embodiment 2

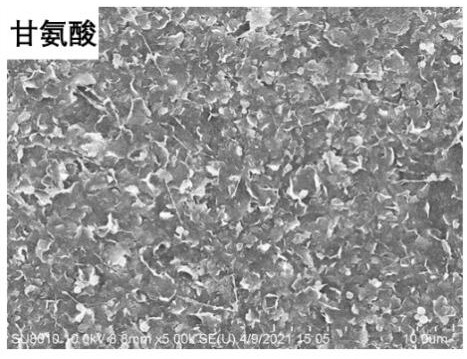

[0028] (1) Weigh 500 mg of montmorillonite and add it to 40 mL of deionized water, stir mechanically for 10 min to disperse the montmorillonite evenly; then add 300 mg of glycine to it, and stir magnetically at room temperature for 7 days to fully disperse the montmorillonite Peel off to obtain a suspension containing lamellar montmorillonite;

[0029] (2) Centrifuge the mixed suspension containing lamella montmorillonite at 4000 rpm / min, wash and centrifuge with deionized water several times to obtain a solid precipitate of lamella montmorillonite;

[0030] (3) Freeze-drying the sheet-layer montmorillonite to obtain sheet-layer montmorillonite powder;

[0031] (4) Weigh 20 mg of lamella montmorillonite and 1.5 g of bacterial cellulose homogenate with a mass concentration of 2 wt%, and disperse them evenly in deionized water to obtain a homogeneous suspension of the two;

[0032] (5) The homogeneous suspension was vacuum filtered to obtain the MMT / BC wet film; the MMT / BC wet ...

Embodiment 3

[0038] (1) Weigh 500 mg of montmorillonite and add it to 40 mL of deionized water, and stir mechanically for 10 min to disperse the montmorillonite evenly; then add 300 mg of urea to it, and stir magnetically at room temperature for 7 days to fully disperse the montmorillonite Peel off to obtain a suspension containing lamellar montmorillonite;

[0039] (2) Centrifuge the mixed suspension containing lamella montmorillonite at 4000 rpm / min, wash and centrifuge with deionized water several times to obtain a solid precipitate of lamella montmorillonite;

[0040] (3) Freeze-drying the sheet-layer montmorillonite to obtain sheet-layer montmorillonite powder;

[0041] (4) Weigh 50 mg of lamella montmorillonite and 1.5 g of bacterial cellulose homogenate with a mass concentration of 2 wt%, and disperse them evenly in deionized water to obtain a homogeneous suspension of the two;

[0042] (5) The homogeneous suspension was vacuum filtered to obtain the MMT / BC wet film; the MMT / BC wet f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com