Low dielectric and low loss boride LTCC material and preparation method thereof

A boride, low-loss technology, applied in the field of microwave dielectric ceramics, can solve the problems of harmful environment, high cost, electrode reaction, etc., and achieve the effects of improving stability, stable preparation method, and high commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

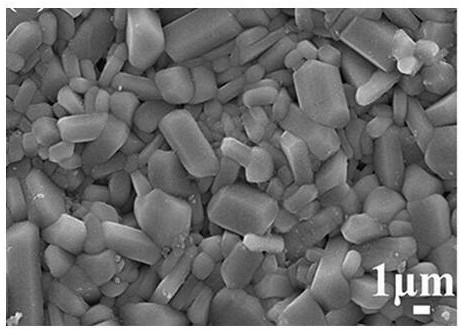

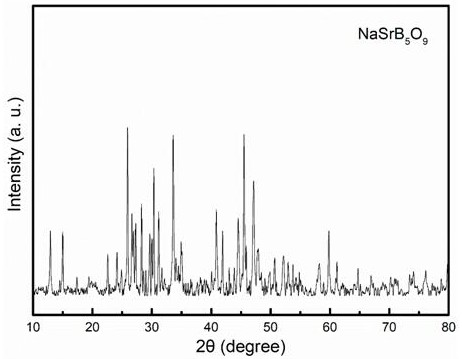

Image

Examples

Embodiment 1

[0023] Step 1, preparation by hydrothermal method AB B 5 o 9 Powder: as SrCO 3 、BaCO 3 ,, CaCO 3 、NaNO 3 、LiNO 3 , and H 3 BO 3 High-purity powder is used as raw material, according to the chemical expression AB B 5 o 9 Carry out weighing batching to form mixed powder, mixed powder is dissolved in deionized water, prepares to obtain the mixed solution that mass concentration is 10%; Then add dehydrated alcohol and silane coupling agent in mixed solution, wherein dehydrated alcohol accounts for total mixed solution The volume of the solution is 30%, and the silane coupling agent accounts for 10% of the total volume of the mixed solution; the mixed solution is transferred to a high-pressure reactor, and the temperature is gradually raised to 120°C for 24 hours, cooled to room temperature, and circulated with deionized water and absolute ethanol Wash by centrifugation for three times, and dry at 90°C for 4 hours to obtain AB B 5 o 9 powder.

[0024] Step 2, ball...

Embodiment 2

[0031] Step 1, preparation by hydrothermal method AB B 5 o 9 Powder: as SrCO 3 、BaCO 3 ,, CaCO 3 、NaNO 3 、LiNO 3 , and H 3 BO 3 High-purity powder is used as raw material, according to the chemical expression AB B 5 o 9Carry out weighing batching to form mixed powder, mixed powder is dissolved in deionized water, prepares to obtain the mixed solution that mass concentration is 10%; Then add dehydrated alcohol and silane coupling agent in mixed solution, wherein dehydrated alcohol accounts for total mixed solution The volume of the solution is 30%, and the silane coupling agent accounts for 10% of the total volume of the mixed solution; the mixed solution is transferred to a high-pressure reactor, and the temperature is gradually raised to 150 ° C for 12 hours, cooled to room temperature, and circulated with deionized water and absolute ethanol Wash by centrifugation for three times, and dry at 90°C for 4 hours to obtain AB B 5 o 9 powder.

[0032] Step 2, bal...

Embodiment 3

[0039] Step 1, preparation by hydrothermal method AB B 5 o 9 Powder: as SrCO 3 、BaCO 3 ,, CaCO 3 、NaNO 3 、LiNO 3 , and H 3 BO 3 High-purity powder is used as raw material, according to the chemical expression AB B 5 o 9 Carry out weighing batching to form mixed powder, mixed powder is dissolved in deionized water, prepares to obtain the mixed solution that mass concentration is 10%; Then add dehydrated alcohol and silane coupling agent in mixed solution, wherein dehydrated alcohol accounts for total mixed solution The volume of the solution is 30%, and the silane coupling agent accounts for 10% of the total volume of the mixed solution; the mixed solution is transferred to a high-pressure reactor, and the temperature is gradually raised to 130°C for 18 hours, cooled to room temperature, and circulated with deionized water and absolute ethanol Wash by centrifugation for three times, and dry at 90°C for 4 hours to obtain AB B 5 o 9 powder.

[0040] Step 2, ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com