Preparation method and application of carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with heterojunction structure

A carbon nanofiber, tin disulfide technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as the shuttle effect of lithium polysulfide, and achieve clean and environmentally friendly production processes. Simple, transformative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: what this embodiment records is a kind of preparation method of carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with heterojunction structure, described method steps are as follows:

[0022] Step 1: Dissolve 16 mg of thioacetamide and 32-80 mg of tin tetrachloride in 10 mL of isopropanol, add carbon nanofibers with a diameter of 1 cm, react in hydrothermal reaction at 180 ° C for 24 hours, and cool naturally to room temperature. Dry overnight at a temperature of 70°C to obtain a carbon nanofiber, tin disulfide and tin dioxide composite material with a heterojunction structure;

[0023] Step 2: Dissolve 200-400 mg of sulfur powder in 5 mL of carbon disulfide to obtain a sulfur solution, and impregnate the carbon nanofibers, tin disulfide and tin dioxide composite materials with a heterojunction structure in step 1 into the sulfur solution to make the sulfur The loading capacity is 1.5-3.0mg cm -2 After 5 minutes, it wa...

specific Embodiment approach 2

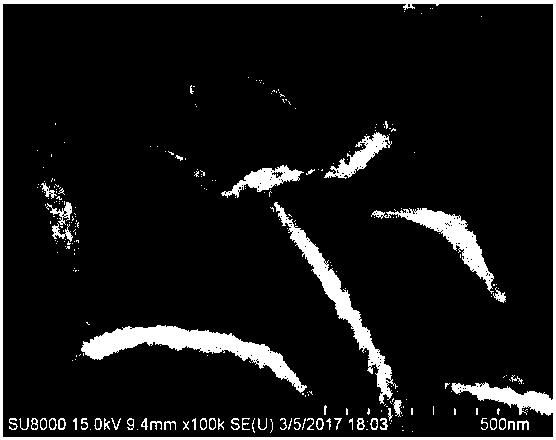

[0024] Specific embodiment two: a method for preparing a carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material with a heterojunction structure described in specific embodiment one, the carbon nanofiber, tin disulfide and disulfide The morphology of tin oxide is a nanosheet array structure with a rough surface.

specific Embodiment approach 3

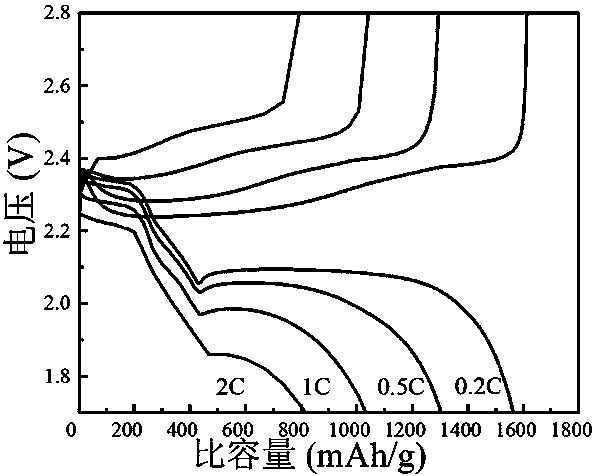

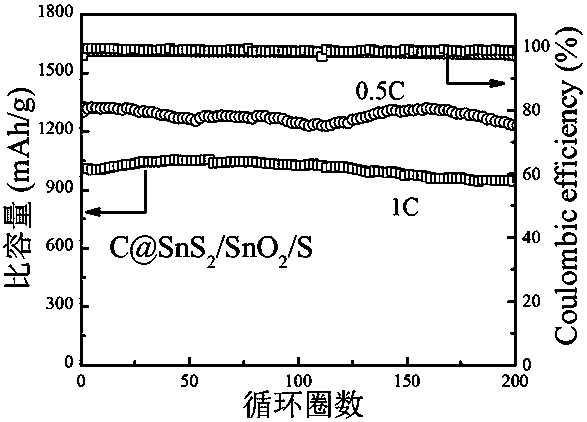

[0025] Embodiment 3: Application of the carbon nanofiber, tin disulfide, tin dioxide and sulfur composite material prepared by the method described in Embodiment 1 or 2 in the positive electrode of lithium-sulfur battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com