A kind of preparation method and application of metal boride and sulfur composite nanomaterial

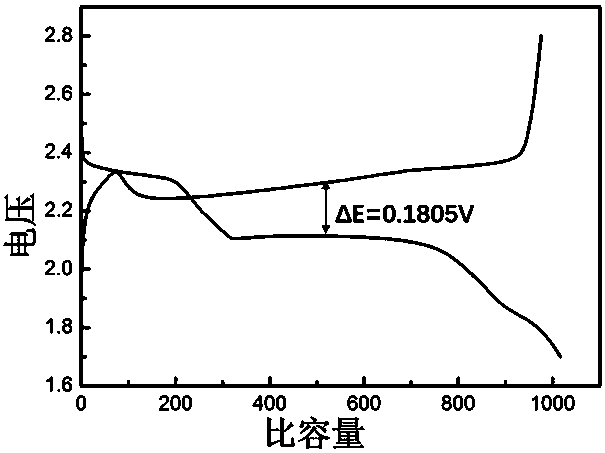

A technology of composite nanomaterials and metal borides, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as lithium polysulfide shuttle effect, and achieve a clean and environmentally friendly preparation process. The effect of simplicity and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: what this embodiment records is a kind of preparation method of metal boride and sulfur composite nanomaterial, described method step is as follows:

[0023] Step 1: dissolving sodium borohydride and NaOH in deionized water under inert gas protection conditions to obtain a reducing agent solution, wherein the concentrations of sodium borohydride and NaOH are both 0.5-3 M; dissolving the metal salt in deionized water, To obtain a metal salt solution with a concentration of 0.5-2M, separate the obtained reducing agent solution and metal salt solution into an ice-water bath for 15 minutes;

[0024] Step 2: Under the protection of an inert gas, slowly add the metal salt solution after the ice-water bath to an equal volume of reducing agent solution at a rate of one drop per second, and stir for 30 minutes to obtain a dry product, and then place the dry product at 350- High-temperature calcination at 500°C for 2-10 hours to obtain metal borides;

[...

specific Embodiment approach 2

[0026] Specific embodiment two: the preparation method of a metal boride and sulfur composite nanomaterial described in specific embodiment one, in step one, the metal salt is a kind of in iron salt, cobalt salt, nickel salt, molybdenum salt .

specific Embodiment approach 3

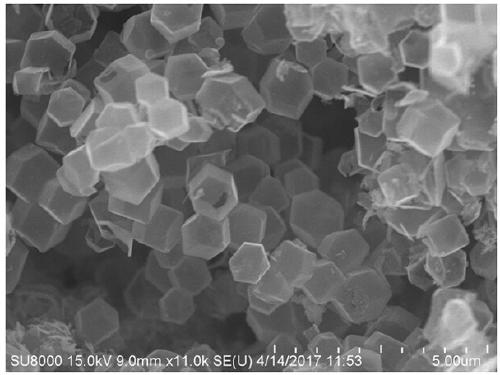

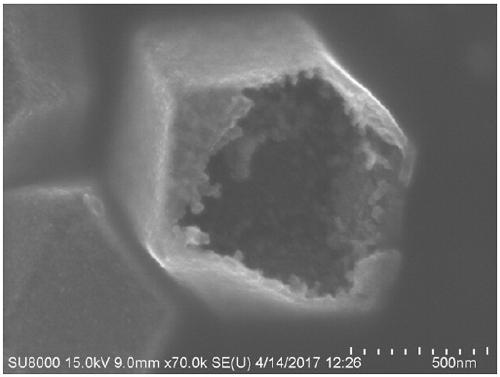

[0027] Specific embodiment three: the preparation method of a metal boride and sulfur composite nanomaterial described in specific embodiment one, in step two, the morphology of the metal boride is nanowire, nanorod, nanosphere, nanosheet , nanoparticle, nanoarray, nanoflower, nanocube, determined by its experimental temperature, adding speed and concentration; material surface defects can be regulated by calcination temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com