The synthetic method of trimethoxyboroxane

A technology of trimethoxyboron, synthesis method, applied in chemical instruments and methods, compounds containing periodic table Group 3/13 elements, organic chemistry, etc. , three wastes and other problems, to achieve the effect of improving reversible specific capacity, high purity, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

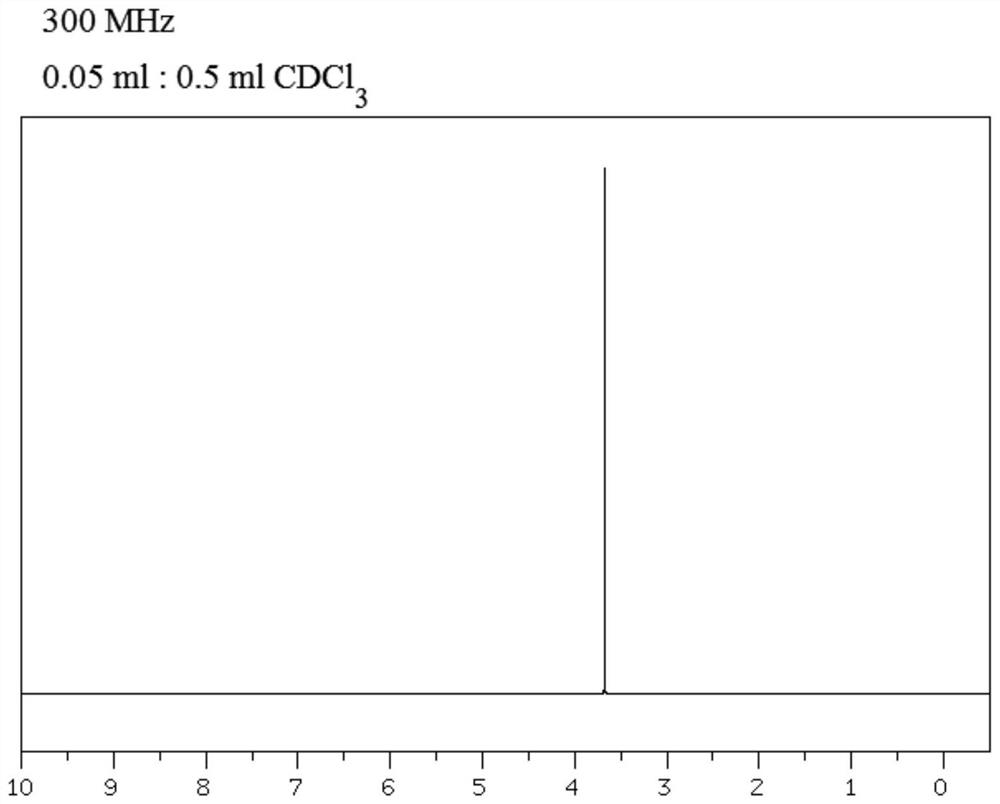

[0017] At -80°C, add 1 mol of borane methyl sulfide into the Schlenk reaction flask, add 6 mol of THF to it, then mix for 20 seconds under a vacuum of 0.7 Pa, then pass carbon dioxide into it, control the pressure at 100 kPa, first in The temperature was raised to 20°C within 15min, then heated at a heating rate of 3°C / min for 10min, then heated at a heating rate of 3°C / min for 10min, and then heated to 80°C, no borane methyl sulfide was detected, and the reaction ended ( After heating up to 80°C, the timed reaction only takes 30 minutes) to obtain trimethoxyboroxane.

[0018] The obtained trimethoxyboroxane density is 1.1g / cm 3 , boiling point 130°C 760mmHg, purity 99.56%, acid value 34ppm, water content 28ppm, yield 95.3%.

Embodiment 2

[0020] At -70°C, add 1 mol of borane methyl sulfide into the Schlenk reaction flask, add 8 mol of THF to it, then mix for 30 seconds under a vacuum of 0.5 Pa, then pass carbon dioxide into it, control the pressure at 90 kPa, first in Heat up to 30°C within 15min, then heat at a heating rate of 1.5°C / min for 15min, then heat at a heating rate of 2°C / min for 10min, heat up to 72.5°C, detect no borane methyl sulfide, and the reaction ends ( After heating up to 72.5°C, the timed reaction only takes 40 minutes) to obtain trimethoxyboroxane.

[0021] The obtained trimethoxyboroxane density is 1.15g / cm 3 , boiling point 131°C 760mmHg, purity 99.68%, acid value 32ppm, water content 25ppm, yield 95.8%.

Embodiment 3

[0023] At -60°C, add 1 mol of borane methyl sulfide into the Schlenk reaction flask, add 7 mol of THF to it, then mix for 25 seconds under a vacuum of 0.6 Pa, then pass carbon dioxide into it, control the pressure at 95 kPa, first in Heat up to 25°C within 15min, then heat at a heating rate of 2°C / min for 10min, then heat at a heating rate of 2°C / min for 15min, then heat up to 75°C, detect no borane methyl sulfide, and the reaction ends ( After heating up to 75°C, the timed reaction only takes 35 minutes) to obtain trimethoxyboroxane.

[0024] The obtained trimethoxyboroxane density is 1.15g / cm 3 , boiling point 129°C 760mmHg, purity 99.62%, acid value 35ppm, water content 30ppm, yield 96.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com