Nano ZnO/cellulose gel particles and preparation method thereof

A cellulose gel and cellulose fiber technology, applied in the field of nano-ZnO/cellulose gel particles and their preparation, can solve the problems of high temperature, environmental pollution, unfavorable spinning into fiber or film forming process, etc. Reduce, promote the generation, the effect of clean and environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

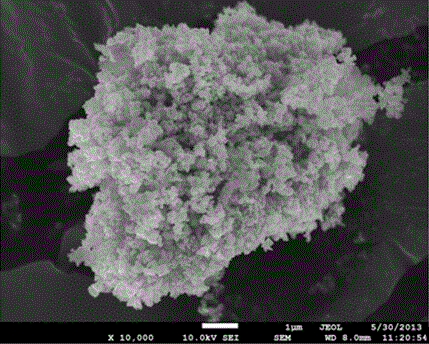

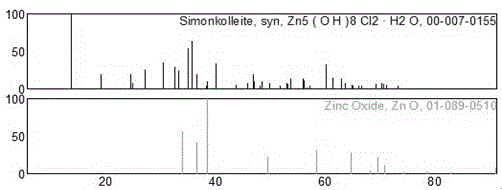

[0034] Add 1 g of wood pulp cellulose to 68% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at 10°C for 1 h. The above liquid-solid material was placed in a water bath at 70° C. and heated and stirred to obtain a transparent and uniform cellulose solution. ZnCl to dissolve cellulose 2 In the aqueous solution, slowly add 10% NaOH aqueous solution dropwise, when the pH value of the system is 9, stop the dropwise addition, and let it stand for 24 hours to obtain the ZnO precursor / cellulose gel. ) put the ZnO precursor / cellulose gel into the hydrothermal synthesis kettle, and carry out the hydrothermal reaction under the conditions of pH=9 and temperature of 120°C, and the reaction time is 6h. Wash the ZnO / cellulose gel to be free of Cl - Finally, put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new material of ZnO / cellulose gel particles is obtained.

[0035] At the same time, ZnO...

Embodiment 2

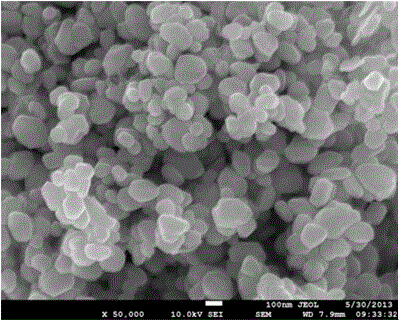

[0040] Add 1g of bamboo pulp cellulose to 65% (wt%) ZnCl 2 In the aqueous solution, pretreat for 3 hours in a low-temperature bath at -10°C. The above liquid-solid material was placed in a water bath at 60° C. and heated and stirred to obtain a transparent and uniform cellulose solution. ZnCl to dissolve cellulose 2 In the aqueous solution, slowly add 5% NaOH aqueous solution dropwise, when the pH value of the system is 7, stop the dropwise addition, and let it stand for 36 hours to obtain the ZnO precursor / cellulose gel. ) Put the ZnO precursor / cellulose gel into the hydrothermal synthesis kettle, and carry out the hydrothermal reaction under the conditions of pH=7 and temperature of 170°C, and the reaction time is 4h. Wash the ZnO / cellulose gel to be free of Cl - Finally, put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new material of ZnO / cellulose gel particles is obtained.

[0041] Depend on Figu...

Embodiment 3

[0043] Add 1 g of cotton pulp cellulose to 70% (wt%) ZnCl 2 In aqueous solution, pretreatment in a low-temperature bath at 30°C for 0.5h. The above liquid-solid material was placed in a water bath at 90° C. and heated and stirred to obtain a transparent and uniform cellulose solution. ZnCl to dissolve cellulose 2 In the aqueous solution, slowly add 20% NaOH aqueous solution dropwise, when the pH value of the system is 10, stop the dropwise addition, and let stand for 48 hours to obtain ZnO precursor / cellulose gel. ) put the ZnO precursor / cellulose gel into a hydrothermal synthesis kettle, and conduct a hydrothermal reaction under the conditions of pH=10 and temperature 100°C, and the reaction time is 10h. Wash the ZnO / cellulose gel to be free of Cl - Finally, put it in an ultra-low temperature refrigerator, and place the sample in a freeze dryer after freezing. After drying, a new material of ZnO / cellulose gel particles is obtained.

[0044] Depend on Figure 9 It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com