Monodisperse pure rutile type or rutile type and anatase type composite phase titanic oxide hollow sub-micron ball and preparation method

A titanium dioxide, anatase type technology, applied in the field of nanomaterials, can solve the problems of discoloration of organic dye molecules, poor stability of white pigments, high density of white pigments, etc., and achieves the effects of mild conditions, controllable product size, and easy synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1). Monodisperse PS / TiO was prepared by the method in the invention patent application number: 200610011885.0 2 Submicron spheres, approximately 350nm in size. PS spheres with cores of 240 nm, TiO2 composed of titania nanoparticles 2 The shell thickness is 55nm.

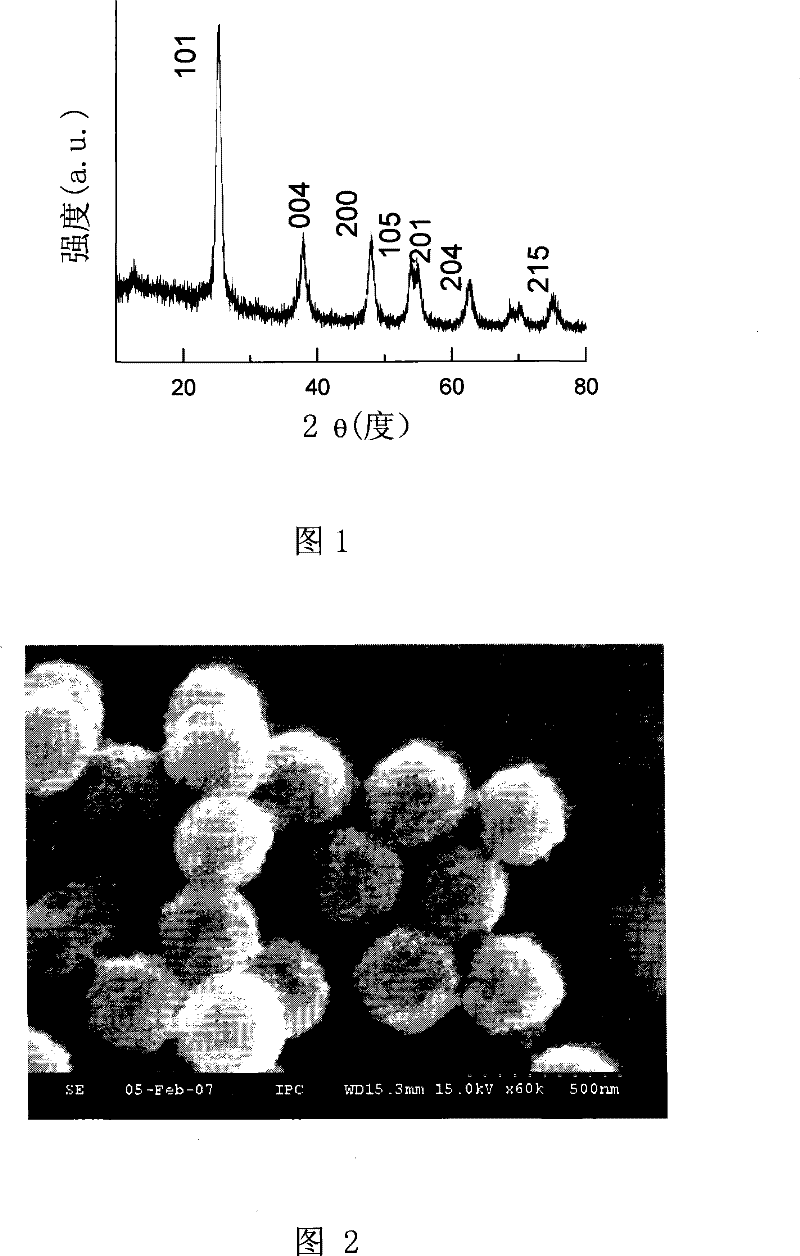

[0040] (2). Disperse the colloidal particles coated with titanium dioxide on the surface of polystyrene microspheres obtained in step (1) into deionized water, the concentration range can be 1-50g / L, and transfer it to the hydrothermal reaction kettle after magnetic stirring , reacted at 80 °C for 24 hours, and its shell was composed of anatase-structured TiO nanoparticles. The obtained samples were centrifuged, dried and stored for further operation. Its crystal structure and morphology are as figure 1 , as shown in 2, the outer shell is composed of anatase structure titanium dioxide nanoparticles with a size of 5-50 nm, and the inner core is PS spheres. Since the amorphous titanium dioxide becomes nano...

Embodiment 2

[0043] (1). Monodisperse PS / TiO was prepared by the method in the invention patent application number: 200610011885.0 2 submicron spheres.

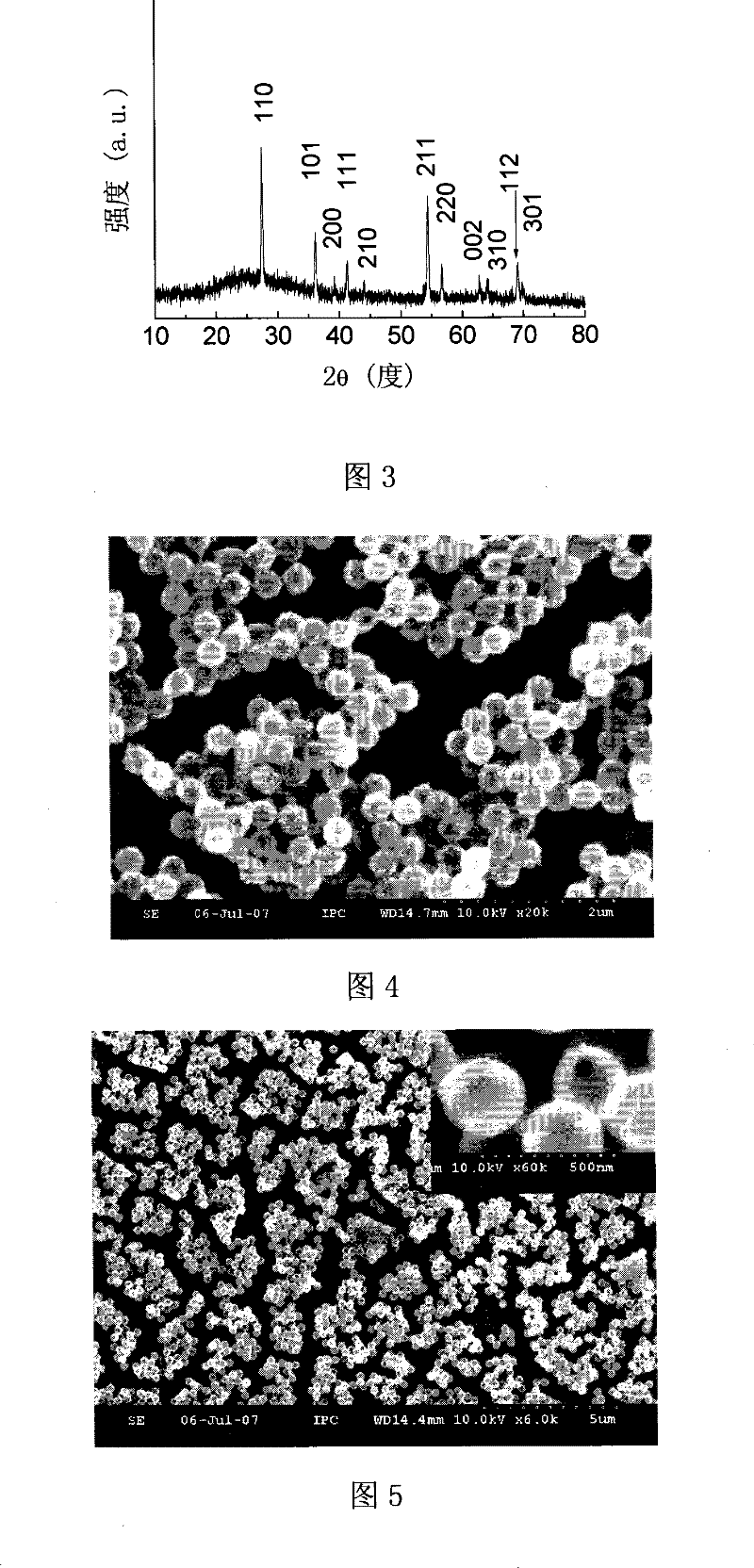

[0044] (2). The sample obtained in step (1) was sintered in a tube furnace at 900° C. for 2 hours, and then cooled to room temperature. The obtained sample is monodispersed, smooth and compact titanium dioxide hollow submicron spheres, and the mass content of rutile is 100%. It looks like Figure 5 Shown (the small figure is the local enlarged view of the obtained titanium dioxide hollow submicron sphere with smooth and compact surface). The size of the whole titanium dioxide hollow submicron sphere is about 315nm, and the inner cavity size is about 235nm. The density of titanium dioxide hollow submicron spheres is about 2.5g / cm 3 .

Embodiment 3

[0046] (1). Monodisperse PS / TiO was prepared by the method in the invention patent application number: 200610011885.0 2 submicron spheres.

[0047] (2). The sample obtained in step (1) was sintered in a tube furnace at 700° C. for 4 hours, and then cooled to room temperature. The obtained sample is monodisperse, smooth and dense titanium dioxide hollow submicron spheres, and the mass content of rutile is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com