A kind of polyethylene glycol/cellulose triacetate phase change microcapsule and preparation method thereof

A technology of cellulose triacetate and phase-change microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., and can solve problems such as environmental pollution, difficulty in degradation, and inability to meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add cellulose triacetate and polyethylene glycol (molecular weight: 8000) with a mass ratio (mass ratio of cellulose triacetate to polyethylene glycol, the same below) of 1:3 into dichloromethane, and stir at room temperature After 3h, a transparent and homogeneous solution was obtained. Set the inlet temperature of the spray drying device to 100°C, the compressed air pressure to 0.18MPa, and the air velocity to 30m 3 / h, with the speed of 1.4mL / min, the solution is transported into the spray drying device by the peristaltic pump, and the polyethylene glycol / cellulose triacetate phase change microcapsules are obtained by spray drying.

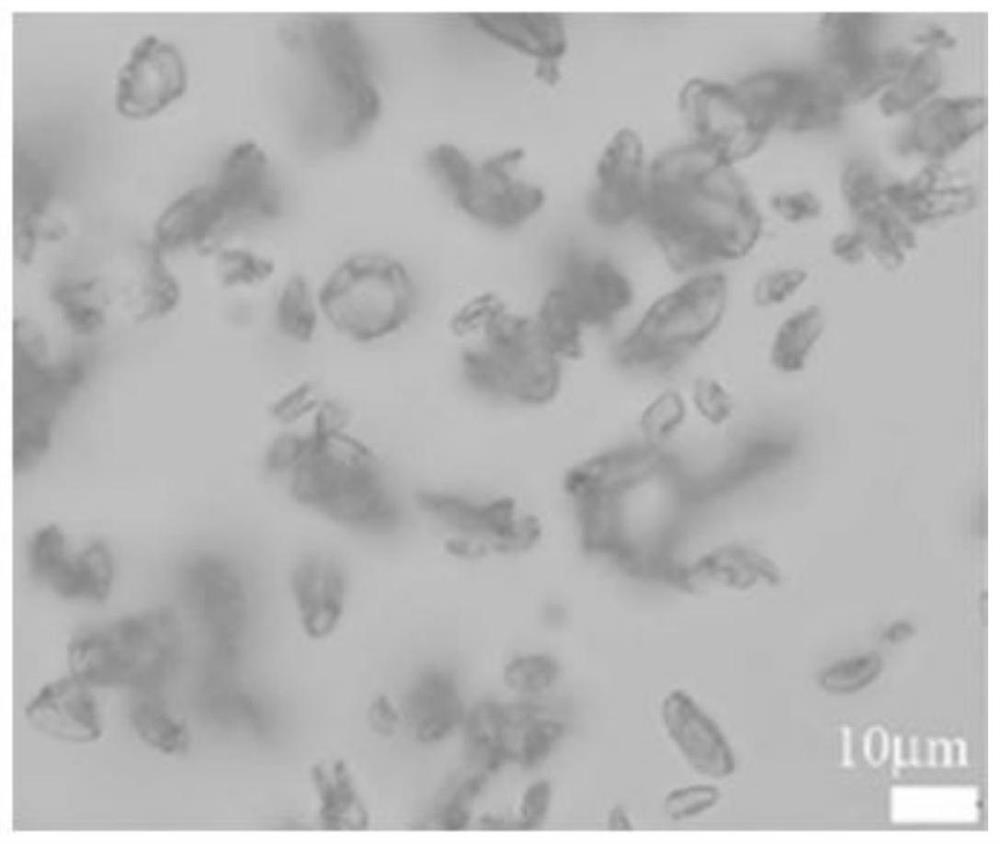

[0028] The optical microscope image of the prepared polyethylene glycol / cellulose triacetate phase-change microcapsules is as follows figure 1 As shown, in the polyethylene glycol / cellulose triacetate phase-change microcapsules, cellulose triacetate is on the outside, polyethylene glycol is on the inside, and the particles are spherical...

Embodiment 2

[0030] Add cellulose triacetate and polyethylene glycol (molecular weight: 800) with a mass ratio of 1:5 into dichloromethane, and stir at room temperature for 3 hours to obtain a transparent and uniform solution. Set the inlet temperature of the spray drying device to 60°C, the compressed air pressure to 0.14MPa, and the air velocity to 40m 3 / h, with the speed of 4.2mL / min, the solution is transported into the spray drying device by the peristaltic pump, and the polyethylene glycol / cellulose triacetate phase change microcapsules are obtained by spray drying.

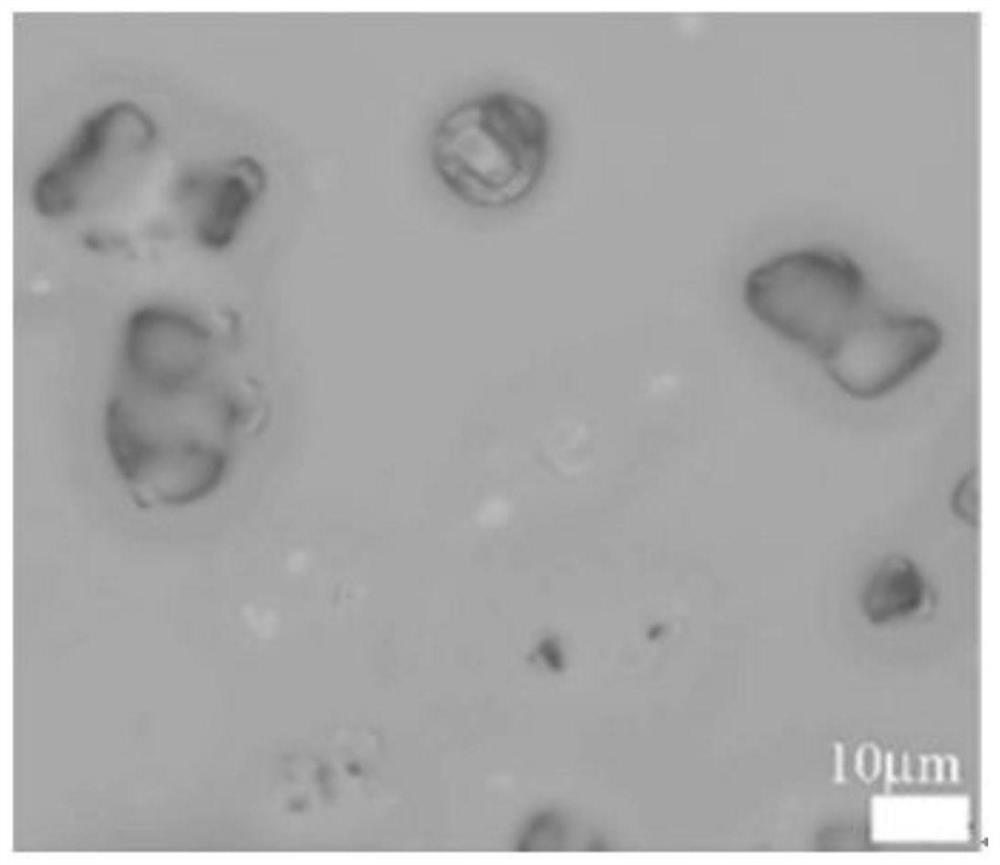

[0031] The optical microscope image of the prepared polyethylene glycol / cellulose triacetate phase-change microcapsules is as follows figure 2 As shown, in the polyethylene glycol / cellulose triacetate phase-change microcapsules, cellulose triacetate is on the outside, polyethylene glycol is on the inside, and the particles are spherical and uniform in size, with a particle size ranging from 5 to 10 μm. The heat of ph...

Embodiment 3

[0033] Add cellulose triacetate and polyethylene glycol (molecular weight: 1000) at a mass ratio of 1:4 into dichloromethane, and stir at room temperature for 3 hours to obtain a transparent and uniform solution. Set the inlet temperature of the spray drying device to 80°C, the compressed air pressure to 0.16MPa, and the air velocity to 20m 3 / h, with the speed of 2.8mL / min, the solution is transported into the spray drying device by the peristaltic pump, and the polyethylene glycol / cellulose triacetate phase change microcapsules are obtained by spray drying.

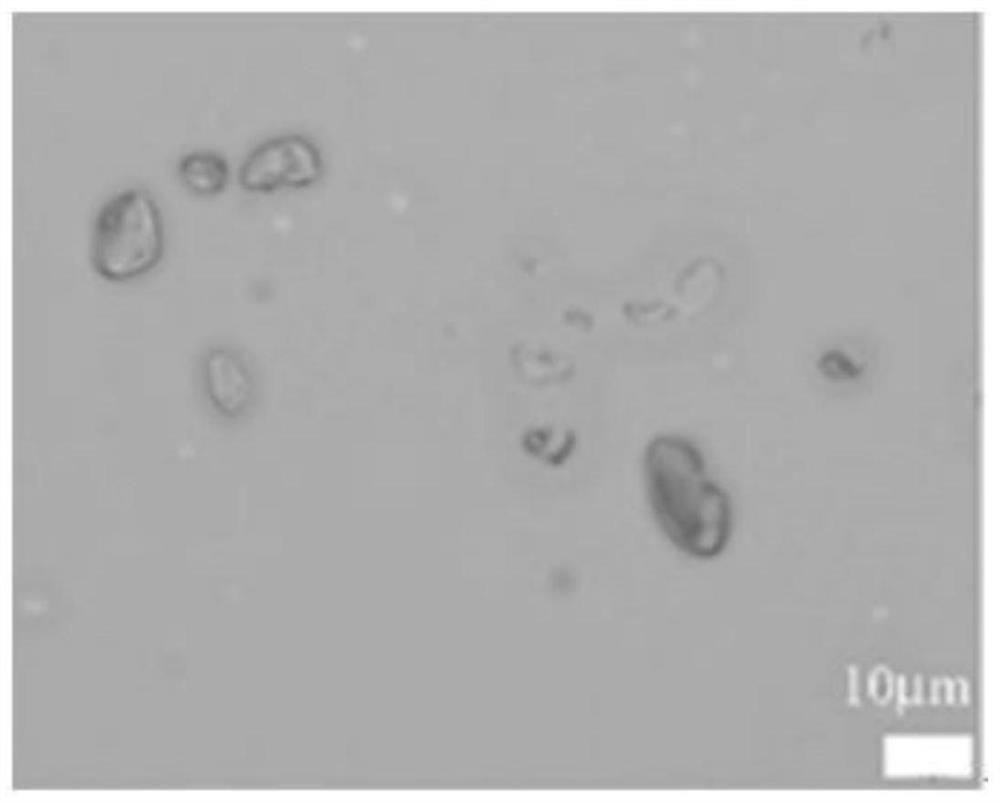

[0034] The optical microscope image of the prepared polyethylene glycol / cellulose triacetate phase-change microcapsules is as follows image 3 As shown, in the polyethylene glycol / cellulose triacetate phase-change microcapsules, cellulose triacetate is on the outside, polyethylene glycol is on the inside, and the particles are spherical and relatively uniform in size, with a particle size ranging from 2 to 15 μm. The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com