Light-cured polyurethane acrylate emulsion containing mosquito-repellent plant extract and applied to spinning coating

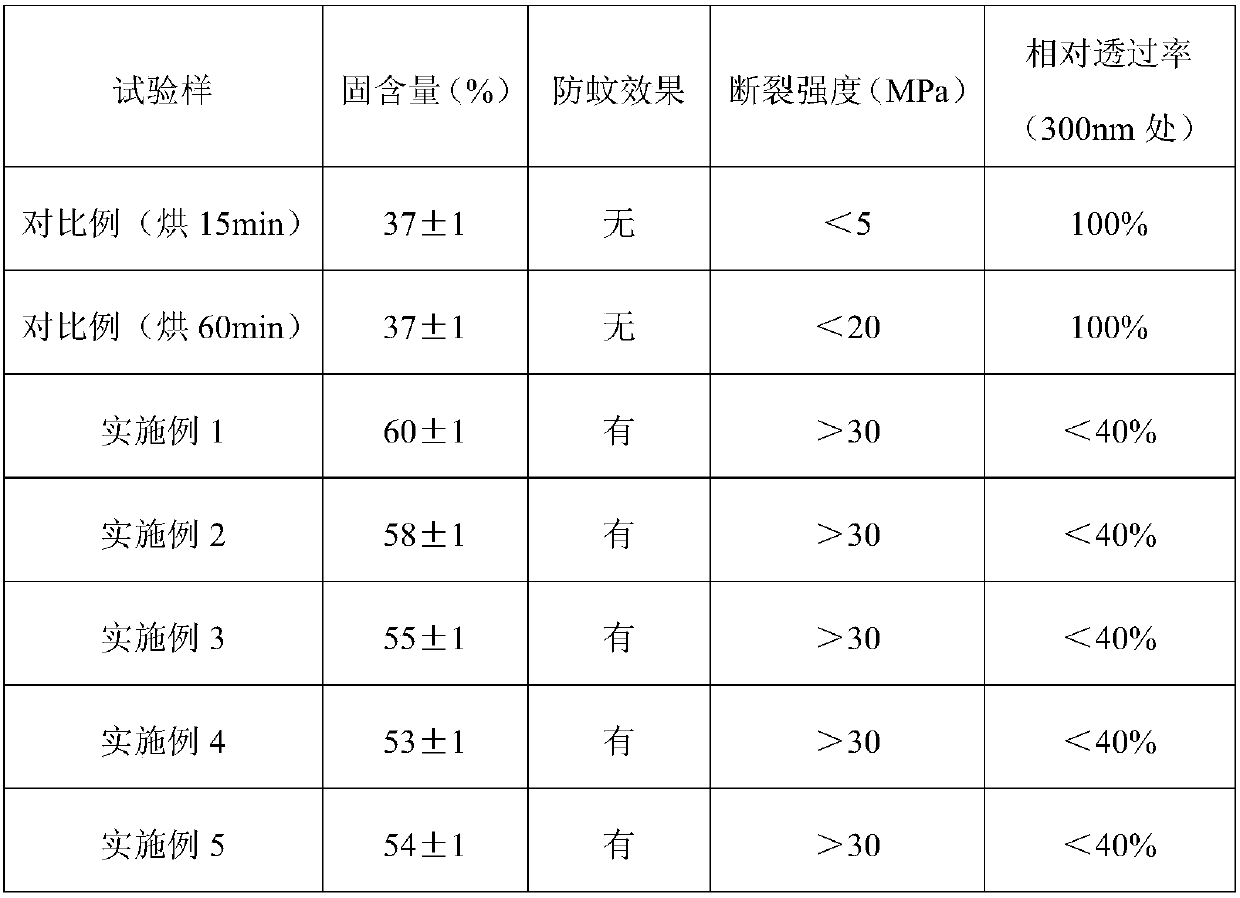

A technology of polyurethane acrylate and mosquito repellent plants, which is applied in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc. It can solve the problem of no polymer emulsion and achieve excellent film-forming properties , clean preparation process and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of insect repellent plant extract:

[0027] Add 20g of pyrethrum powder with a moisture content of no more than 2% to 220g of absolute ethanol, reflux extraction for 5 times, the extraction temperature is 75°C, about 48min each time, filter the extract, and combine the filtered extract, after decolorization treatment Concentrate to an extract solution with a mass concentration of about 48%.

[0028] Preparation of emulsion:

[0029] (1) 5.92g dimethylolbutyric acid and 18g side chain containing non-ionic hydrophilic group dibasic alcohol (YMERN-120, Perstorp company), 120g polycaprolactone diol with molecular weight 1000 is heated to 112 ℃ Melt and mix, dehydrate at a vacuum degree of 0.09MPa, add 56.2g of hexamethylene diisocyanate (HDI), and react at a temperature of 98°C for 92min to obtain a polyurethane prepolymer (a);

[0030] (2) Add 26.5g of hydroxypropyl acrylate to the prepolymer (a), control the temperature at 93°C and continue the reaction for ...

Embodiment 2

[0033] Preparation of insect repellent plant extract:

[0034] Add 20g of pyrethrum powder with a water content not exceeding 2% to 260g of absolute ethanol, reflux extraction 6 times, the extraction temperature is 75°C, and each time is about 43min, filter the extract, and combine the filtered extract, after decolorization treatment Concentrate into an extract with a mass concentration of about 42%.

[0035] The preparation of emulsion of the present invention:

[0036] (1) 5.92g dimethylolbutyric acid and 22g side chain containing non-ionic hydrophilic group dibasic alcohol (YMER N-120, Perstorp company), 140g polycaprolactone diol of molecular weight 1000 is warmed up to 117 Melt and mix at ℃, dehydrate at a vacuum degree of 0.08MPa, add 61.1g of hexamethylene diisocyanate (HDI), and react at a temperature of 93℃ for 100min to obtain a polyurethane prepolymer (a);

[0037] (2) Add 23.1g of hydroxypropyl acrylate to the prepolymer (a), control the temperature at 88°C and c...

Embodiment 3

[0040] Preparation of insect repellent plant extract:

[0041] Add 20g of lavender powder with a moisture content of no more than 2% to 260g of absolute ethanol, reflux extraction for 7 times, the extraction temperature is 75°C, about 38min each time, filter the extract, and combine the filtered extract, after decolorization Concentrate into an extract solution with a mass concentration of about 36%.

[0042] The preparation of emulsion of the present invention:

[0043] (1) 5.92g dimethylol butyric acid and 24g side chain containing non-ionic hydrophilic group glycol (YMER N-120, Perstorp company), 160g polytetrahydrofuran diol with a molecular weight of 2000 is heated to 123 ℃ for melting Mix, dehydrate at a vacuum degree of 0.07MPa, add 54.4g of isophorone diisocyanate (IPDI), and react at a temperature of 93°C for 100min to obtain a polyurethane prepolymer (a);

[0044] (2) Add 11.7g of hydroxyethyl acrylate to the prepolymer (a), control the temperature at 80°C and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com