Preparation method and application of protective layer used for metal lithium anode

A metal lithium and protective layer technology, applied in battery electrodes, electrode carriers/current collectors, electrical components, etc., can solve the problems of metal lithium dendrites, etc., to improve electrical conductivity, reduce surface current density, and improve chemical stability. and the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 0.066g potassium ferricyanide and 0.9g PVP, add 50mL deionized water, add 0.1mL hydrochloric acid dropwise to the above solution, and stir at room temperature until completely dissolved;

[0030] (2) Wipe the exposed copper foil with alcohol cotton and then immerse it in the solution of step (1);

[0031] (3) placing the solution in step (2) in a 50°C oven for 60 minutes to obtain a copper foil current collector with a Prussian blue film on the surface;

[0032] (4) drop an aqueous solution containing graphene oxide onto the cleaned surface of the copper foil current collector in step (3), and dry at room temperature to obtain a graphene oxide / Prussian blue modified copper foil.

Embodiment 2

[0034] (1) Take 0.132g potassium ferricyanide and 0.9g PVP, add 50mL deionized water, add 0.1mL hydrochloric acid dropwise to the above solution, and stir at room temperature until completely dissolved;

[0035] (2) Wipe the exposed copper foil with alcohol cotton and then immerse it in the solution of step (1);

[0036] (3) placing the solution in step (2) in a 50°C oven for 60 minutes to obtain a copper foil current collector with a Prussian blue film on the surface;

[0037] (4) drop an aqueous solution containing graphene oxide onto the cleaned surface of the copper foil current collector in step (3), and dry at room temperature to obtain a graphene oxide / Prussian blue modified copper foil.

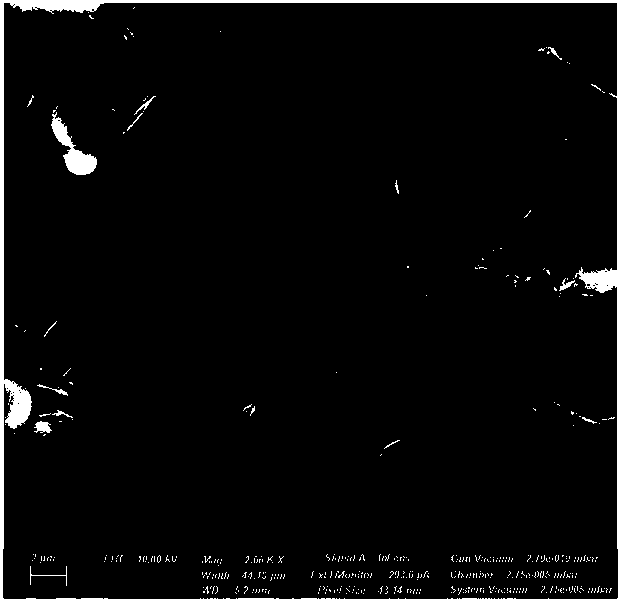

[0038] figure 1 is the SEM picture of the modified current collector prepared in this example, in figure 2 It can be seen that Prussian blue grows uniformly on the surface of the copper foil.

[0039] figure 2 SEM image of the graphene oxide / Prussian blue film prepared in this e...

Embodiment 3

[0042] (1) Take 0.660g potassium ferricyanide and 0.9g PVP, add 50mL deionized water, add 0.1mL hydrochloric acid dropwise to the above solution, and stir at room temperature until completely dissolved;

[0043] (2) Wipe the exposed copper foil with alcohol cotton and then immerse it in the solution of step (1).

[0044] (3) The solution of step (2) was placed in a 50° C. oven for 60 min to react to obtain a copper foil current collector with a Prussian blue film on the surface.

[0045] (4) drop an aqueous solution containing graphene oxide onto the cleaned surface of the copper foil current collector in step (3), and dry at room temperature to obtain a graphene oxide / Prussian blue modified copper foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com