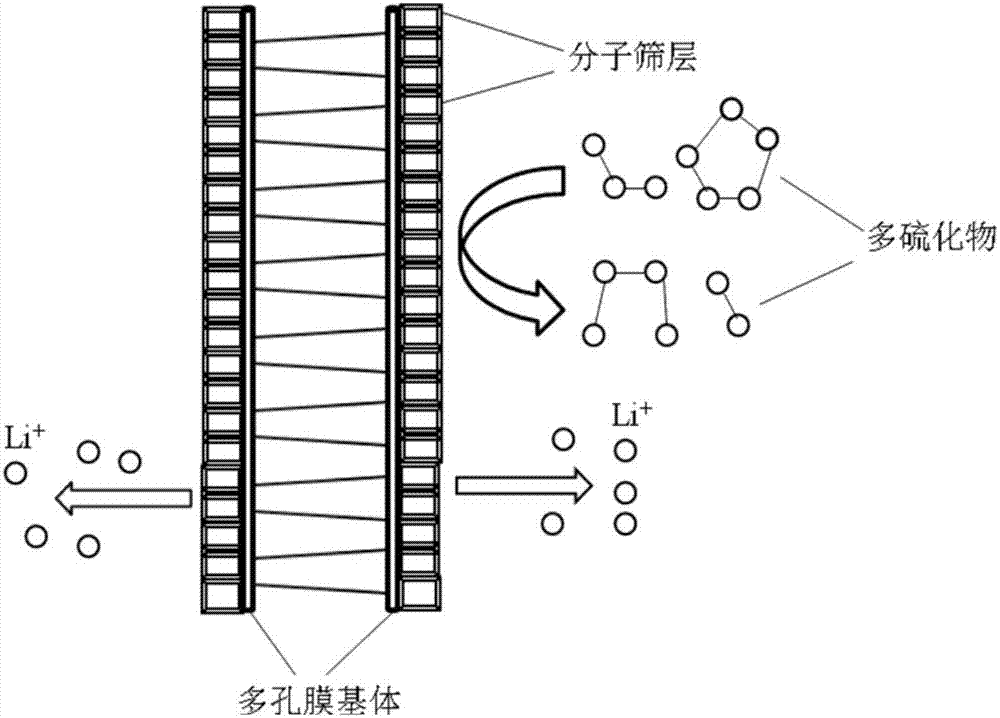

An application of a molecular sieve composite porous membrane in a lithium-sulfur battery

A technology of lithium-sulfur batteries and porous membranes, applied in the field of composite membranes for lithium-sulfur batteries, to achieve good thermal conductivity, inhibit the formation of dendrites, and reduce the effects of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

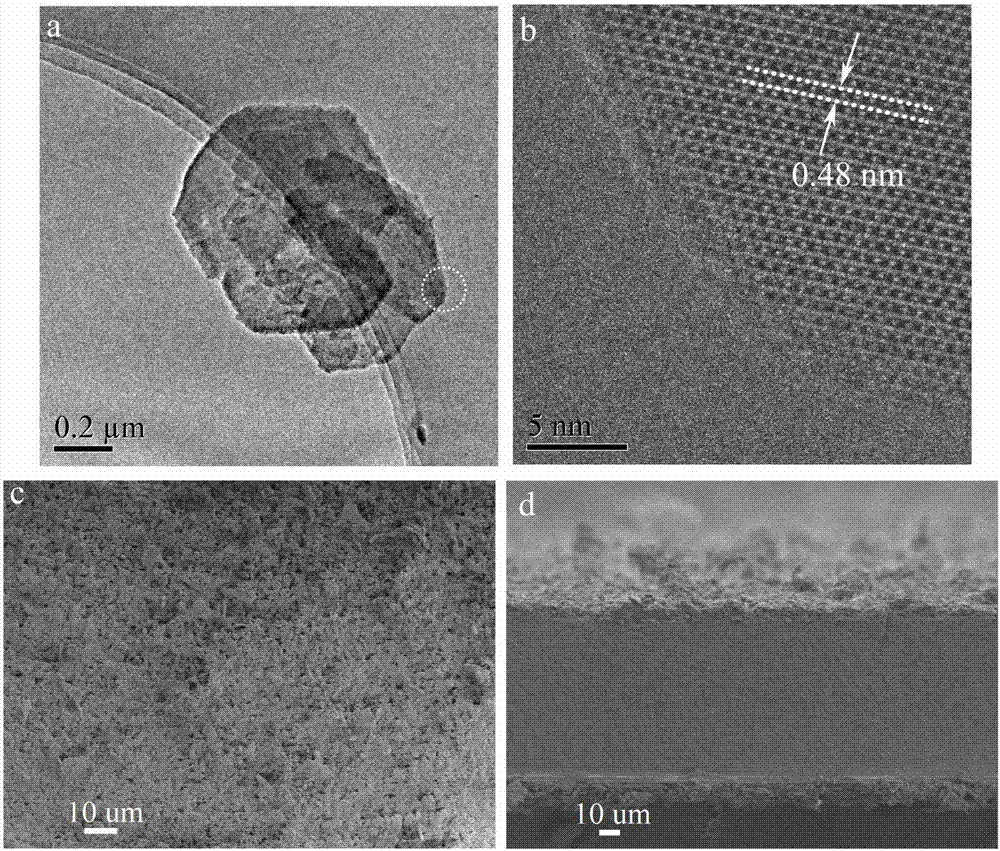

[0038] 7.5 grams of polyetherimide was dissolved in 30 mL of NMP and 10 mL of THF, stirred for 48 hours, and the resulting polymer solution was spread on a glass plate with a thickness of 100 μm, and then quickly immersed in 5 L of water to solidify to form a porous diaphragm.

[0039] Soak the prepared porous membrane in isopropanol for 2 hours to replace the water therein.

[0040]An isopropanol solution of ZSM-35 molecular sieve with a concentration of 80wt.% was prepared, and 20wt.% of Nafion resin was added therein, and sprayed on the surface of the porous membrane. A composite porous membrane (A) was obtained.

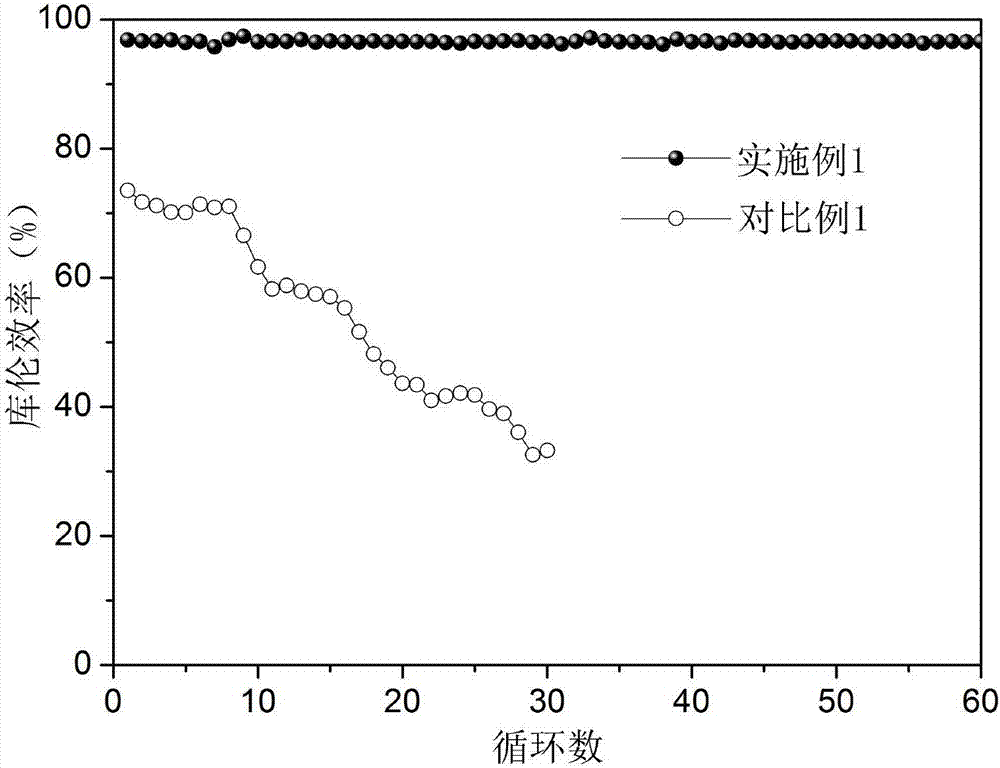

[0041] The prepared composite film was used to assemble a lithium-sulfur battery for testing. The negative electrode of the lithium-sulfur battery is a lithium foil with a thickness of 20 μm, and the positive electrode is prepared by the following method: 25wt.% Super P carbon, 65wt.% elemental sulfur, 10wt.% polyvinylidene fluoride blended in N-methylpyrrolidon...

Embodiment 2

[0047] Same as Example 1, the organic polymer resin is replaced by polysulfone, and other conditions remain unchanged.

Embodiment 3

[0049] Same as Example 1, the organic polymer resin is replaced by polybenzimidazole, the solvent is replaced by NMP, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com