Heat-conducting electromagnetic-shielding high-strength PEEK composite material and preparation method thereof

A technology of electromagnetic shielding and composite materials, applied in the field of thermal conductivity, high-strength PEEK composite materials and their preparation, and electromagnetic shielding, which can solve the problems of poor electromagnetic shielding and poor thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

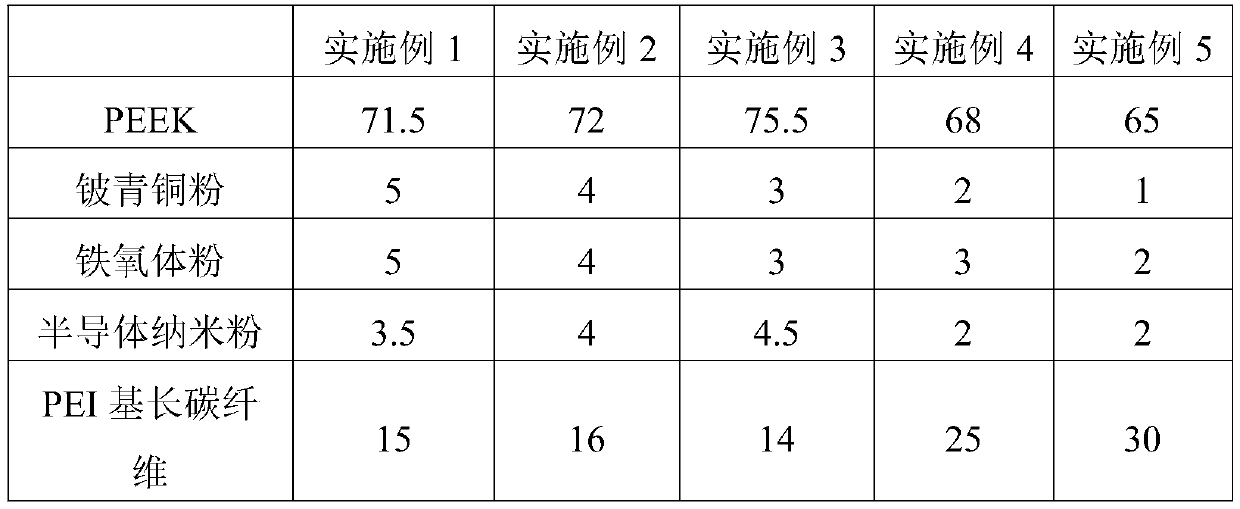

Embodiment 1

[0021] A thermally conductive, electromagnetic shielding, high-strength PEEK composite material, comprising the following components in parts by weight: 75.5 parts of PEEK, 3 parts of beryllium bronze powder, 3 parts of ferrite powder, 3.5 parts of semiconductor nano powder, and 15 parts of PEI-based long carbon fiber;

[0022] Wherein, the beryllium bronze powder contains 2wt% beryllium, 0.3wt% nickel, 0.3wt% cobalt, and the rest is bronze; the average particle size of the semiconductor nanopowder is 200-300nm, and the semiconductor nanopowder is tin antimony oxide ; The PEI-based long carbon fiber is a carbon fiber filament with 1wt% PEI as an adhesive.

[0023] The preparation method of above-mentioned a kind of heat conduction, electromagnetic shielding, high-strength PEEK composite material, comprises the steps:

[0024] (1) beryllium bronze powder, ferrite powder, semiconductor nano-powder are mixed into mixed powder according to the above ratio, coupling agent is added ...

Embodiment 2

[0028] The preparation method of this example is the same as that of Example 1, except that the components by weight are 72 parts of PEEK, 4 parts of beryllium bronze powder, 4 parts of ferrite powder, 4 parts of semiconductor nano powder, and 16 parts of PEI-based long carbon fiber.

Embodiment 3

[0030] The preparation method of this example is the same as that of Example 1, except that the components by weight are 75 parts of PEEK, 4 parts of beryllium bronze powder, 4 parts of ferrite powder, 2 parts of semiconductor nano powder, and 14 parts of PEI-based long carbon fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com