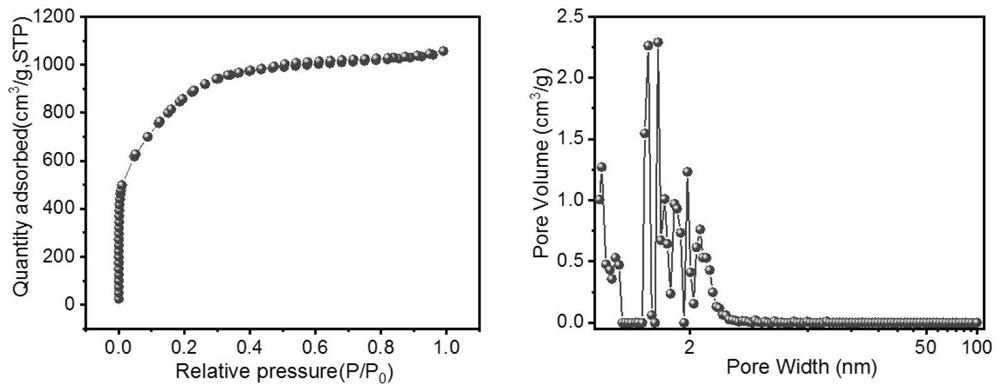

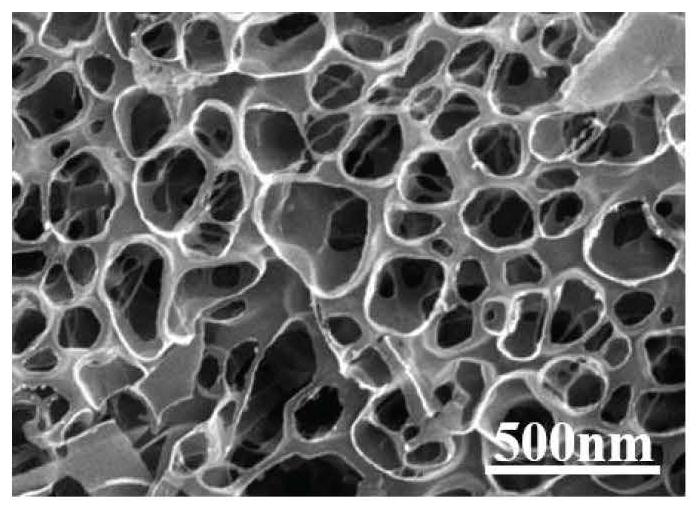

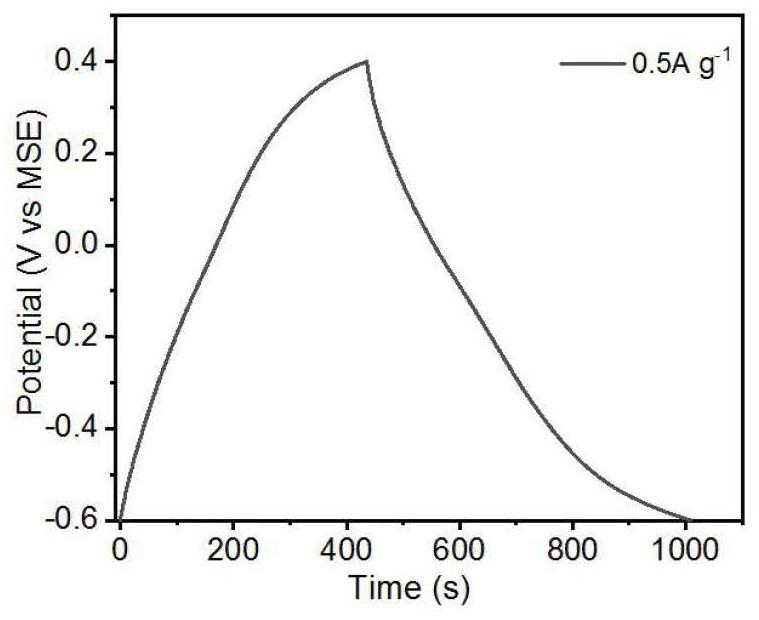

Preparation method and application of three-dimensional porous carbon material with high specific surface area and adjustable pore size distribution

A technology of three-dimensional porous and carbon materials, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of alleviating impact, improving mass transfer efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In a 100 mL beaker, 44 mL of deionized water was added, 16 g of sodium chloride was added to form a saturated solution, 4 g of sucrose, 4 g of dicyandiamide, and 4 g of 200nm calcium carbonate were added in sequence, magnetically stirred at room temperature for 4 hours, and ultrasonicated at 100 Hz for 1 hour.

[0058] After freezing the above mixed liquid with liquid nitrogen, it was quickly transferred to a freeze dryer for freeze drying and kept for 48 hours.

[0059] Weigh 4g of the freeze-dried sample and place it in a large porcelain boat, then sinter it in an argon atmosphere. The first stage calcination temperature is 550℃, the time is 1h, the heating rate is 5℃ / min, and the second stage calcination temperature is 900℃, time 2h, heating rate of 5℃ / min, to obtain three-dimensional porous carbon material.

[0060] Add 250mL of 10% dilute hydrochloric acid solution in a 500mL beaker, then add 4g of carbon material, ultrasonically disperse at room temperature for 1h, magne...

Embodiment 2

[0065] In a 100mL beaker, 44mL of deionized water was added, 16g of sodium chloride was added to form a saturated solution, 4g of sucrose, 4g of dicyandiamine, 4g of 500nm calcium carbonate were sequentially added, magnetically stirred at room temperature for 4h, and ultrasonic for 1h at 100Hz.

[0066] After freezing the above mixture with liquid nitrogen, it was quickly transferred to a freeze dryer for freeze drying and kept for 36 hours.

[0067] Weigh 4g of the freeze-dried sample, place it in a large porcelain boat, and calcine it in an argon atmosphere. The first stage calcination temperature is 550℃, the time is 1h, the heating rate is 5℃ / min, and the second stage calcination temperature is 800℃, time 2h, heating rate of 5℃ / min, to obtain three-dimensional porous carbon material.

[0068] Add 250mL of 10% dilute hydrochloric acid solution in a 500mL beaker, then add 4g of carbon material, ultrasonically disperse for 1h at room temperature, magnetically stir for 4h, then perfo...

Embodiment 3

[0072] Example 3: No NaCl added

[0073] In a 100 mL beaker, 44 mL of deionized water was added, 4 g of sucrose, 4 g of dicyandiamide, and 4 g of 200 nm calcium carbonate were added in sequence, magnetically stirred at room temperature for 4 hours, and ultrasonicated at 100 Hz for 1 hour.

[0074] After freezing the above mixed liquid with liquid nitrogen, it was quickly transferred to a freeze dryer for freeze drying and kept for 48 hours.

[0075] Weigh 4g of the freeze-dried sample and place it in a large porcelain boat, then sinter it in an argon atmosphere. The first stage calcination temperature is 550℃, the time is 1h, the heating rate is 5℃ / min, and the second stage calcination temperature is 900℃, time 2h, heating rate of 5℃ / min, to obtain three-dimensional porous carbon material.

[0076] Add 250mL of 10% dilute hydrochloric acid solution in a 500mL beaker, then add 4g of carbon material, ultrasonically disperse at room temperature for 1h, magnetically stir for 4h, then perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com