Sulfonated polyarylether compound and preparation method thereof, ion-selective composite porous membrane and preparation method and application thereof

A sulfonated polyarylene ether, ion selectivity technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of low ion flux and poor ion selectivity of composite membrane materials, and achieve low cost. , the effect of good flexibility and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention provides a preparation method for the sulfonated polyarylether compound described in the above technical scheme, comprising the following steps:

[0053] Mix the first monomer, the second monomer, the third monomer, an organic solvent, a catalyst, and a water-carrying agent, heat to the reflux temperature of the water-carrying agent for water removal treatment, and then raise the temperature for polycondensation reaction to obtain polyarylether compound;

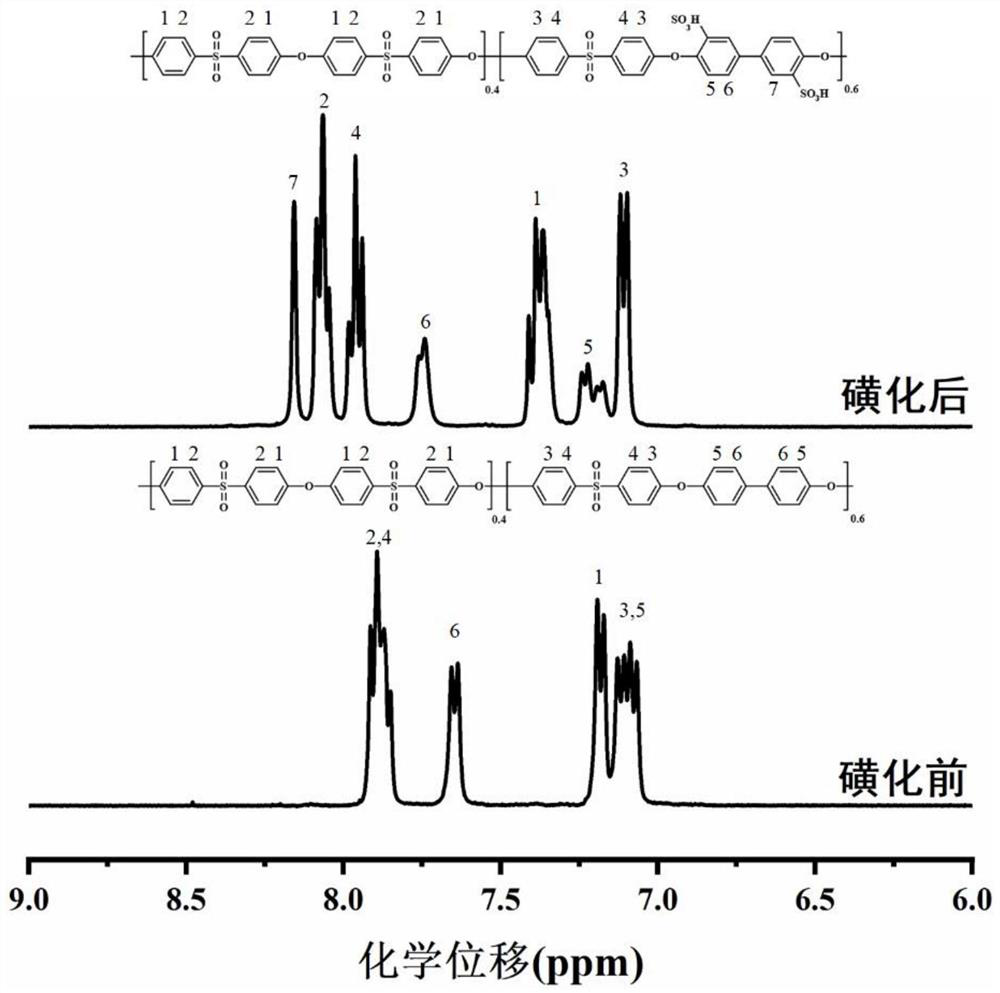

[0054] Sulfonating the polyarylether compound to obtain a sulfonated polyarylether compound having a structure shown in formula I or formula II;

[0055] The first monomer is

[0056] The second monomer is

[0057]

[0058]

[0059] The third monomer is The X is a halogen group.

[0060] In the present invention, the first monomer, the second monomer, the third monomer, the organic solvent, the catalyst and the water-carrying agent are mixed, heated to the reflux temperature of the w...

Embodiment 1

[0086] Under the condition of anhydrous and argon protection, 20.0mmol (5.09g) of 4,4'-difluorodiphenylsulfone, 12.0mmol (2.23g) of 4,4'-dihydroxybiphenyl, 8.0mmol (2.00g) of 4,4'-dihydroxydiphenylsulfone, 4.0g of potassium carbonate, 14mL of toluene and 30mL of sulfolane, and the resulting mixed system was heated to reflux (145°C) under stirring conditions for 4h, so that the toluene was fully Remove the water generated in the system; then heat the obtained system to 180°C for 9 hours, and the viscosity of the system will not change; pour the obtained product system into deionized water to precipitate solid materials, filter, grind the obtained solid materials and wash them with boiling water Washed 3 times, then washed 3 times with ethanol, and dried in vacuum at 80°C to constant weight to obtain a white solid, which is a polyarylether compound. The inherent viscosity of the polyarylether compound is 0.99, and the number average The molecular weight is 119.8kDa, and the disp...

Embodiment 2

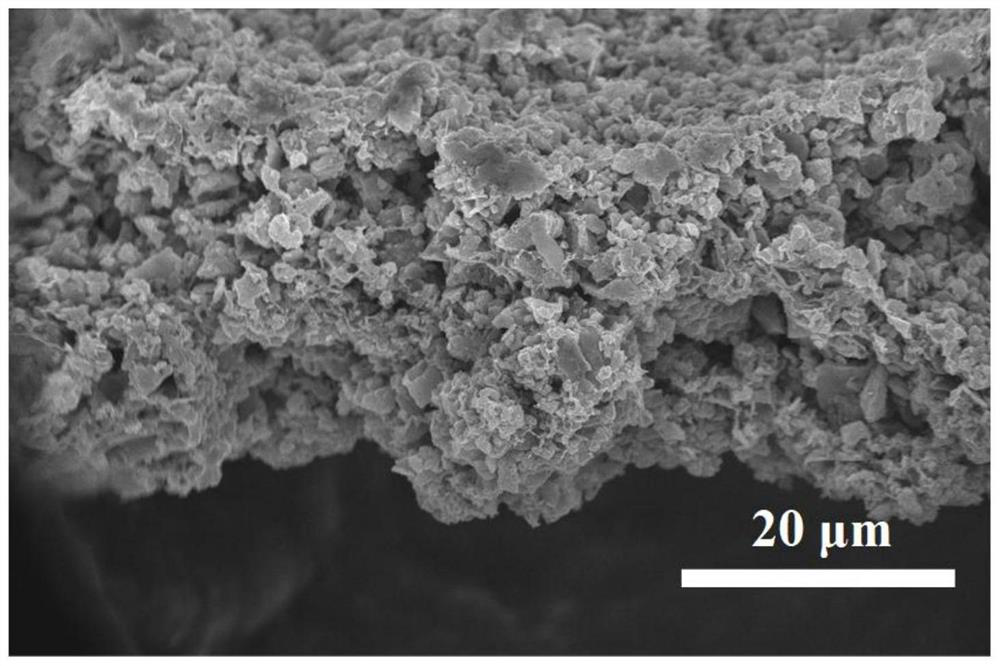

[0090] Mix 3.125 mg of sulfonated polyarylether compound prepared in Example 1, 12.5 mg of manganese dioxide two-dimensional material (thickness 1-5 nm) and 10 mL of N,N-dimethylformamide, and ultrasonically disperse at room temperature for 30 min. Let the obtained system stand still for 30 minutes, take the supernatant and pour it into a suction filter bottle, use nylon 66 organic 0.45 μm filter membrane for vacuum suction filtration, and then vacuum-dry the filter membrane containing the filter cake at 50°C for 24 hours , forming a sulfonated polyarylether-manganese dioxide porous membrane on the upper surface of the filter membrane, the sulfonated polyarylether-manganese dioxide porous membrane can be peeled off from the filter membrane, and the sulfonated polyarylether-manganese dioxide porous membrane can be removed from the filter membrane, and the sulfonated polyarylether- The manganese dioxide porous membrane has a thickness of 22 μm, a pore diameter of 1.23 nm, and a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com