High-selectivity self-microporous polyamide nanofiltration composite membrane and preparation method thereof

A high-selectivity, polyamide nanotechnology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor pollution resistance, insufficient selectivity, and large membrane surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

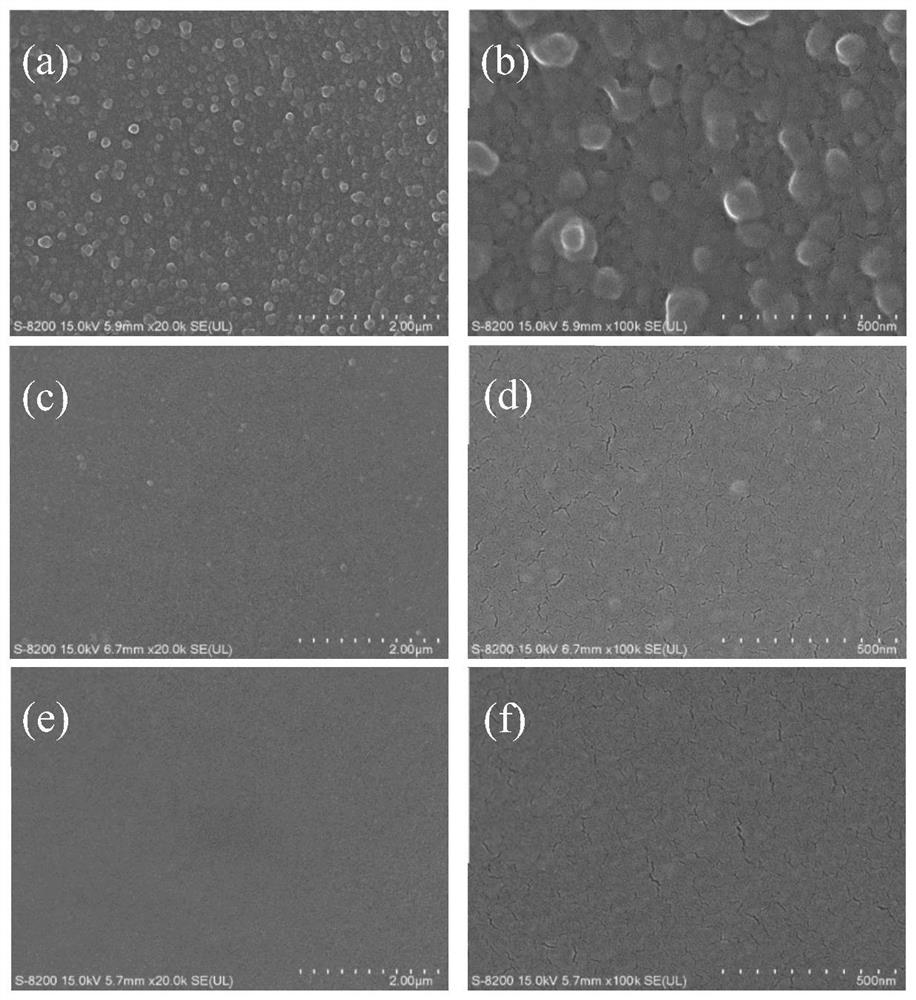

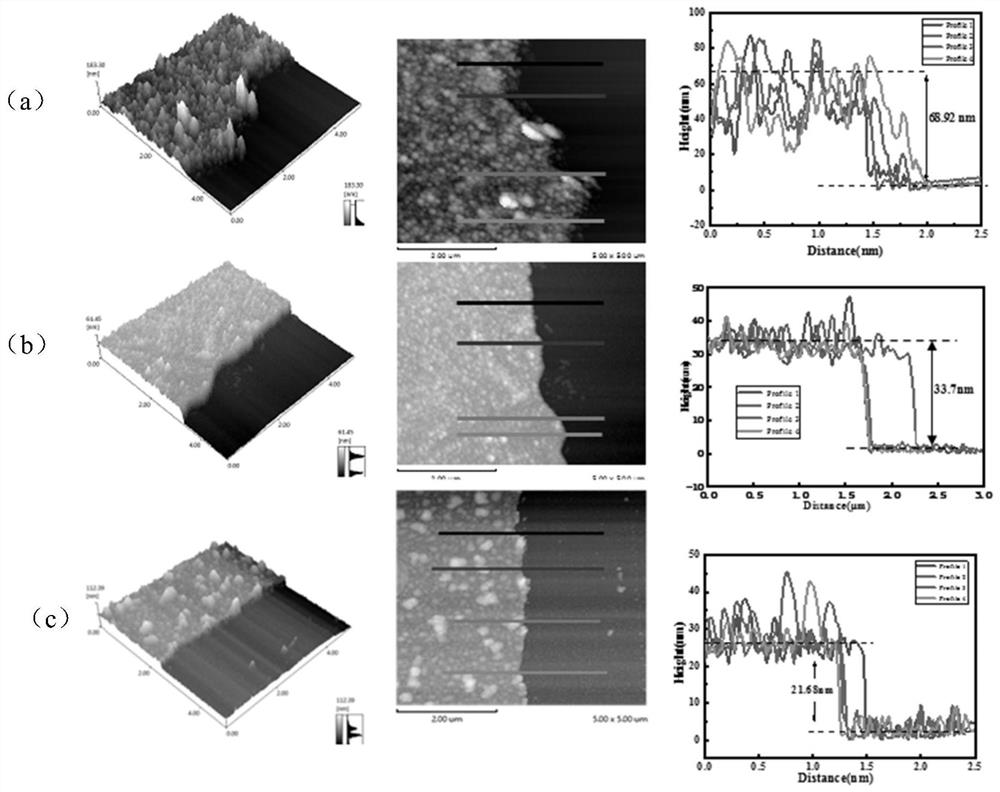

[0043] This embodiment 1 provides a kind of preparation method of highly selective self-microporous polyamide nanofiltration composite membrane, comprising the following steps:

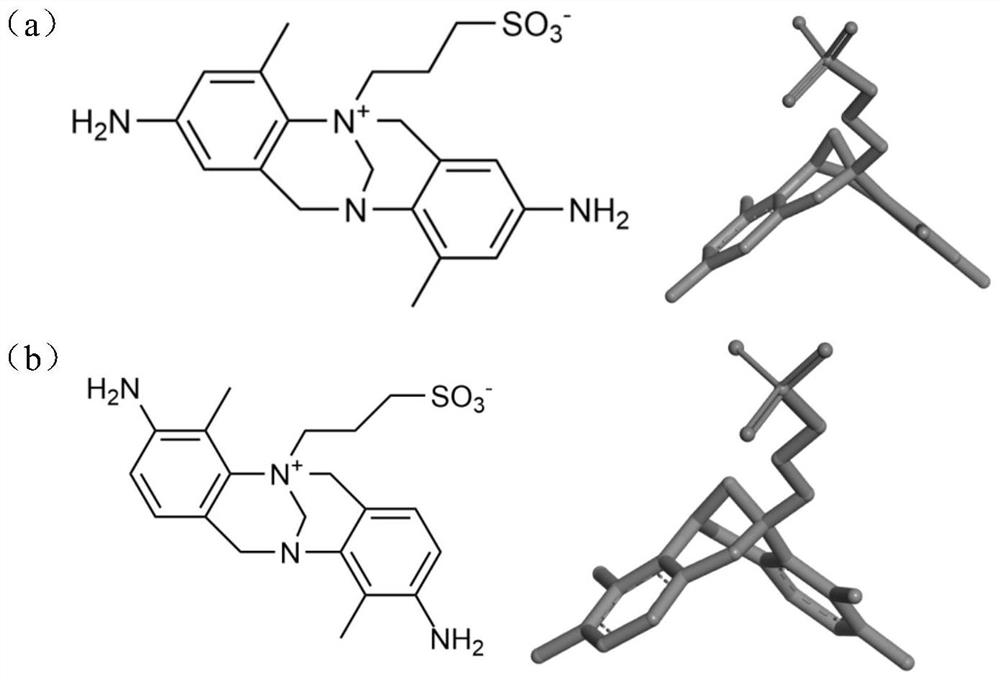

[0044] (1) Dissolve PIP (piperazine) in water to obtain a 1% PIP solution with a mass concentration of 2,8-diamino-4,10-dimethyl-6H,12H-5,11-methylenediphenyl And [1,5]-diaziridine sulfonate was added to the PIP solution at a mass concentration of 1%, and stirred to fully dissolve it to obtain an aqueous phase mixed amine solution;

[0045] (2) Immerse the polysulfone-based membrane in the aqueous mixed amine solution, take it out after soaking for 3 minutes, and dry the residual aqueous-phase mixed amine solution on the surface of the polysulfone-based membrane with an air knife;

[0046] (3) Adopting trimesoyl chloride and organic solvent n-hexane to prepare an organic phase trimesoyl chloride solution with a mass concentration of 0.1%, immersing the upper surface of the film obtained in step (2) in...

Embodiment 2

[0053] This embodiment 2 provides a kind of preparation method of highly selective self-microporous polyamide nanofiltration composite membrane, comprising the following steps:

[0054] (1) Dissolve ethylenediamine in water to obtain an ethylenediamine solution with a mass concentration of 2%, and 3,9-diamino-4,10-dimethyl-6H,12H-5,11-methylenediamine Benzo[1,5]-diazepine propane sulfonate is added to the ethylenediamine solution at a mass concentration of 2%, and stirred to fully dissolve it to obtain an aqueous mixed amine solution;

[0055] (2) Immerse the polysulfone base membrane in the mixed amine solution of the water phase, take it out after soaking for 2 minutes, and dry the residual water phase solution on the surface of the polysulfone base membrane with a rubber roller;

[0056] (3) Adopting pyromellitic acid chloride and organic solvent n-heptane to prepare an organic phase pyromellitic chloride solution with a mass concentration of 0.2%, immersing the upper surfa...

Embodiment 3

[0060] This embodiment 3 provides a kind of preparation method of highly selective self-microporous polyamide nanofiltration composite membrane, comprising the following steps:

[0061] (1) Dissolving piperazine in water to obtain a piperazine solution with a mass concentration of 1%, 3,9-diamino-4,10-dimethyl-6H,12H-5,11-methylenedibenzo[ 1,5]-diazacycline sulfonate was added to the PIP solution at a mass concentration of 1%, and stirred to fully dissolve it to obtain an aqueous phase mixed amine solution;

[0062] (2) Immerse the polysulfone base membrane in the mixed amine solution of the water phase, take it out after soaking for 2 minutes, and dry the residual water phase solution on the surface of the polysulfone base membrane with an air knife;

[0063] (3) Adopting trimesoyl chloride and organic solvent n-hexane to prepare an organic phase trimesoyl chloride solution with a mass concentration of 0.1%, immersing the upper surface of the film obtained in step (2) in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeate flux | aaaaa | aaaaa |

| Permeate flux | aaaaa | aaaaa |

| Permeate flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com