Multilayer membrane electrode and preparation method and application thereof

A multi-layer film and electrode technology, applied in the direction of electrode manufacturing, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems of weakened conductivity of electrode materials, low energy density of batteries, and reduced energy density of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of multilayer film electrode

[0036] The multilayer film electrodes are fabricated in MPECVD at one time. Experiment using CH 4 、SH 4 and H 2 as a gas source. A 25 μm thick copper foil was used as the substrate. First, cut the copper foil into discs with a diameter of 7mm according to the size of the electrode pole pieces, and put them on the sample holder of the reaction furnace cavity. Then pre-evacuate the furnace body to 5×10 -2 torr. The carbon layer in the sample is the plasma decomposition and precipitation of CH 4 and H 2 Made, SiO 2 It is the plasma decomposition and precipitation of SiH 4 and H 2 Produced, oxygen comes from residual oxygen in the gas. There is no additional heating source other than the plasma. Decompose CH in the test 4 and SiH 4The instrument power is 600W. The carbon layer is synthesized at a pressure of 3torr, and the mixed gas contains H 2 and CH 4 The ratio is 2:1. The synthetic gas pressure of t...

Embodiment 2

[0037] Example 2 Structural characterization of the multilayer film electrode obtained in Example 1

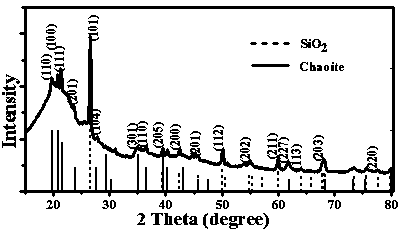

[0038] The structure and morphology of the multilayer film electrodes were analyzed by scanning electron microscope (SEM), Raman test, transmission electron microscope (TEM) and selected electron diffraction (SAED). The chemical composition and crystal structure of the material were analyzed by XPS and XRD.

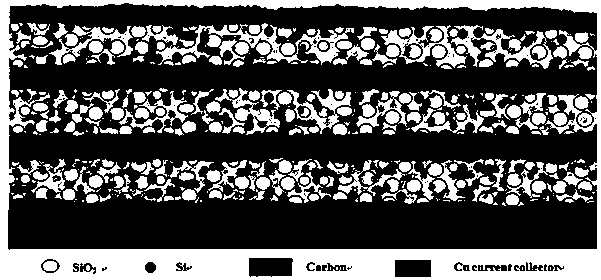

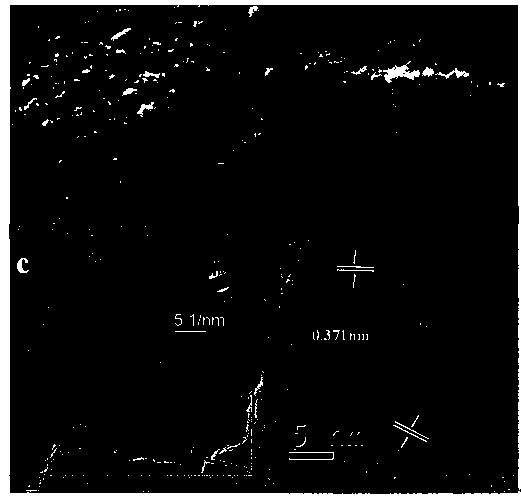

[0039] figure 2 For the SEM and TEM characterization data of the prepared multilayer film electrodes, the structure and microscopic morphology of the electrode materials are shown. figure 2 a is the top view of the upper surface of the multilayer film electrode. It can be seen from the figure that the surface of the membrane is covered by a uniform carbon layer. SiO under the carbon layer can be resolved 2 It is distributed in an island shape, and there are certain gaps between the islands. figure 2 b is the cross-sectional picture of the multilayer film electrode...

Embodiment 3

[0043] Embodiment 3 The electrochemical performance characterization of the multilayer film electrode obtained in embodiment 1

[0044] We tested the electrochemical performance of the multilayer film electrode, which was assembled into a double-electrode button cell with metal lithium sheet as the counter electrode. Cell assembly was performed in a glove box filled with an argon atmosphere. As a comparative experiment, we also assembled pure SiO 2 &Si membrane electrode battery. The electrodes do not use any binder and conductive agent. We first conducted a cyclic voltammetry test on the multilayer film electrode, and the voltage window of the test was between 0-3.0V, such as Image 6 shown. In the first cycle, an obvious reduction peak appeared at the position of 0.6V, which corresponds to the decomposition of the electrolyte and the formation of the SEI film. This peak disappeared in the next cycle, indicating that the electrode material has formed a stable SEI fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com