Double-sleeve extrusion die for extruding chalcogenide glass optical fiber preform rod and use method

An optical fiber preform and chalcogenide glass technology, which is applied in the field of extrusion molds, can solve the problems of difficult to prepare optical fiber preforms with complex structures, difficult to precisely control the uniformity of the core-to-package ratio, etc., and achieves easy uniformity and uniformity control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

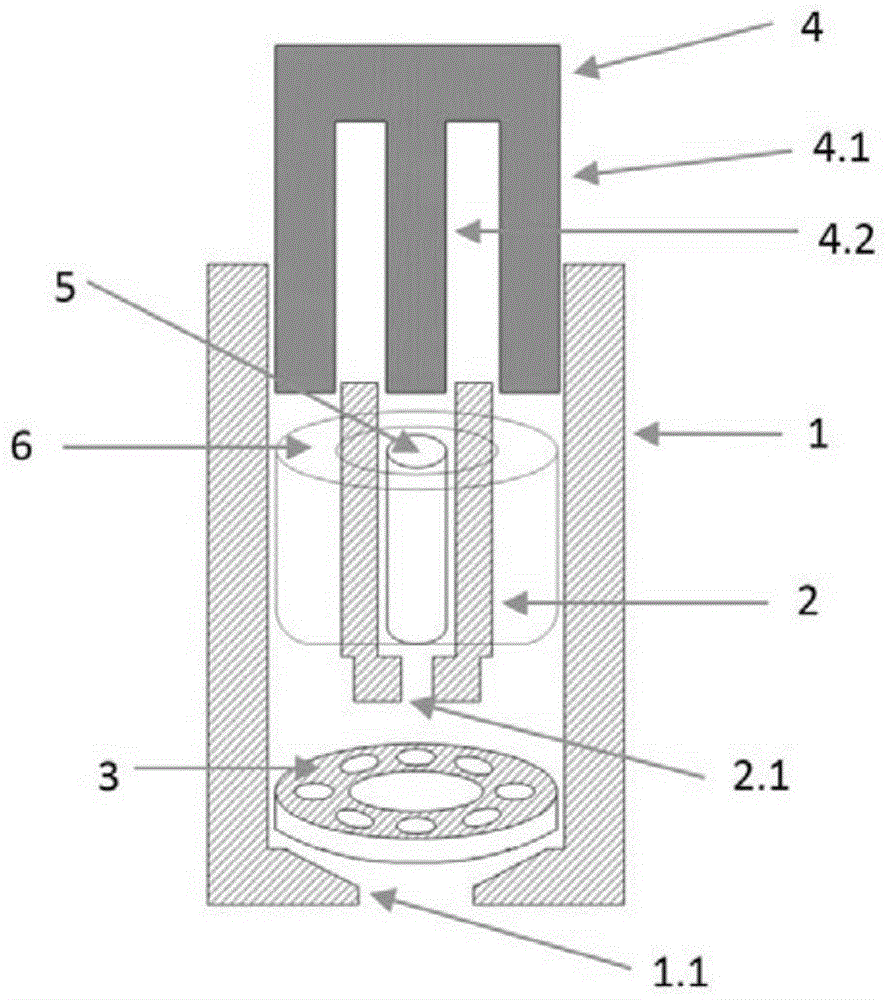

[0044] Example 1: Extrusion of a chalcogenide glass optical fiber preform with a core-to-clad ratio of 4:5.

[0045] In this embodiment, the outlet sections of the inner sleeve nozzle and the outer sleeve nozzle are circular, and the inner diameter ratio is 4:5.

[0046] The extrusion method includes the following steps:

[0047]1) Prepare a chalcogenide glass rod as the fiber core material. The diameter of the chalcogenide glass rod is equal to the inner diameter of the inner sleeve. Ensure that the glass rod is just placed in the inner sleeve. The length of the glass rod is less than the depth of the inner sleeve. 2) Prepare the chalcogenide glass casing as the cladding material. The chalcogenide glass casing is obtained by a common drilling method; the outer diameter of the obtained chalcogenide glass casing is equal to the inner diameter of the outer sleeve, ensuring that the chalcogenide glass casing is just placed In the outer sleeve, the inner diameter of the chalcogen...

Embodiment 2

[0048] Example 2: Extrusion of a chalcogenide glass optical fiber preform with a core-to-clad ratio of 1:15

[0049] In this embodiment, the outlet sections of the inner sleeve nozzle and the outer sleeve nozzle are circular, and the inner diameter ratio is 1:15.

[0050] The extrusion method includes the following steps:

[0051] 1) Prepare a chalcogenide glass rod as the fiber core material. The diameter of the chalcogenide glass rod is equal to the inner diameter of the inner sleeve. Ensure that the glass rod is just placed in the inner sleeve. The length of the glass rod is less than the depth of the inner sleeve. 2) Prepare the chalcogenide glass casing as the cladding material. The chalcogenide glass casing is obtained by a common drilling method; the outer diameter of the obtained chalcogenide glass casing is equal to the inner diameter of the outer sleeve, ensuring that the chalcogenide glass casing is just placed In the outer sleeve, the inner diameter of the chalcog...

Embodiment 3

[0052] Embodiment 3: Extrusion of chalcogenide glass optical fiber preforms whose core wrapping shapes are circular and regular hexagonal respectively.

[0053] In this embodiment, the outlet section of the inner sleeve nozzle is circular, and the outlet section of the outer sleeve nozzle is a regular hexagon.

[0054] The extrusion method includes the following steps:

[0055] 1) Prepare a chalcogenide glass rod as the fiber core material. The diameter of the chalcogenide glass rod is equal to the inner diameter of the inner sleeve. Ensure that the glass rod is just placed in the inner sleeve. The length of the glass rod is less than the depth of the inner sleeve. 2) Prepare the chalcogenide glass casing as the cladding material. The chalcogenide glass casing is obtained by a common drilling method; the outer diameter of the obtained chalcogenide glass casing is equal to the inner diameter of the outer sleeve, ensuring that the chalcogenide glass casing is just placed In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com