Piston rod partial chrome plating device

A piston rod and partial technology, which is applied in the field of partial chrome plating of piston rod parts, can solve the problems of difficult processing, small tolerance range, and difficulty in obtaining uniform coating, and achieve the effects of improving production efficiency and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

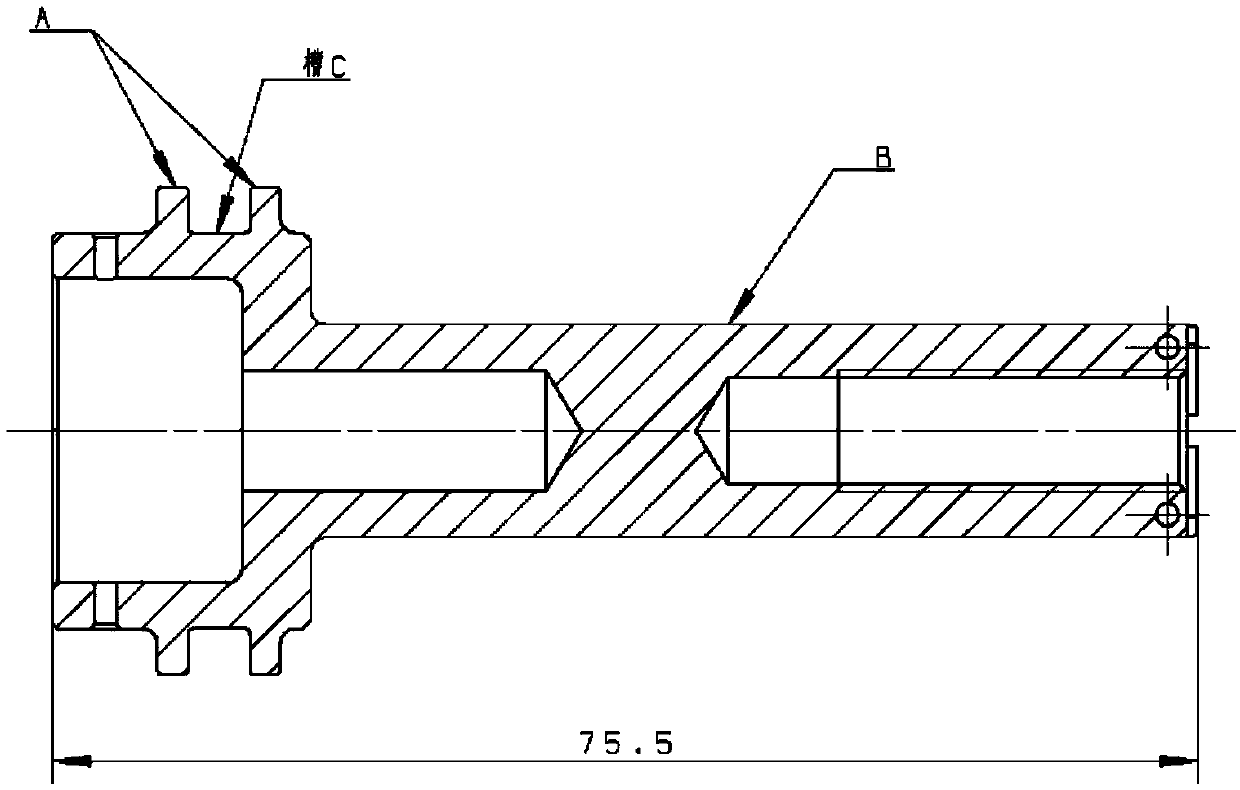

[0031] In the present invention, if figure 1 As shown, the surface A of the large end and the surface B of the rod are required to be chrome-plated, and chrome is allowed to transition 1mm from the chrome-plated to the non-chrome-plated surface. Because the diameters of the piston rod and the big end are different, the deposition rate of the chromium layer at the big end is higher than that of the rod. In order to ensure that the uniformity of the chromium layer meets the requirements, the rod and the big end of the piston rod should be chrome-plated separately. Therefore, it is necessary to design Manufacture the chrome-plated components of the piston rod and the chrome-plated components of the large end of the piston rod.

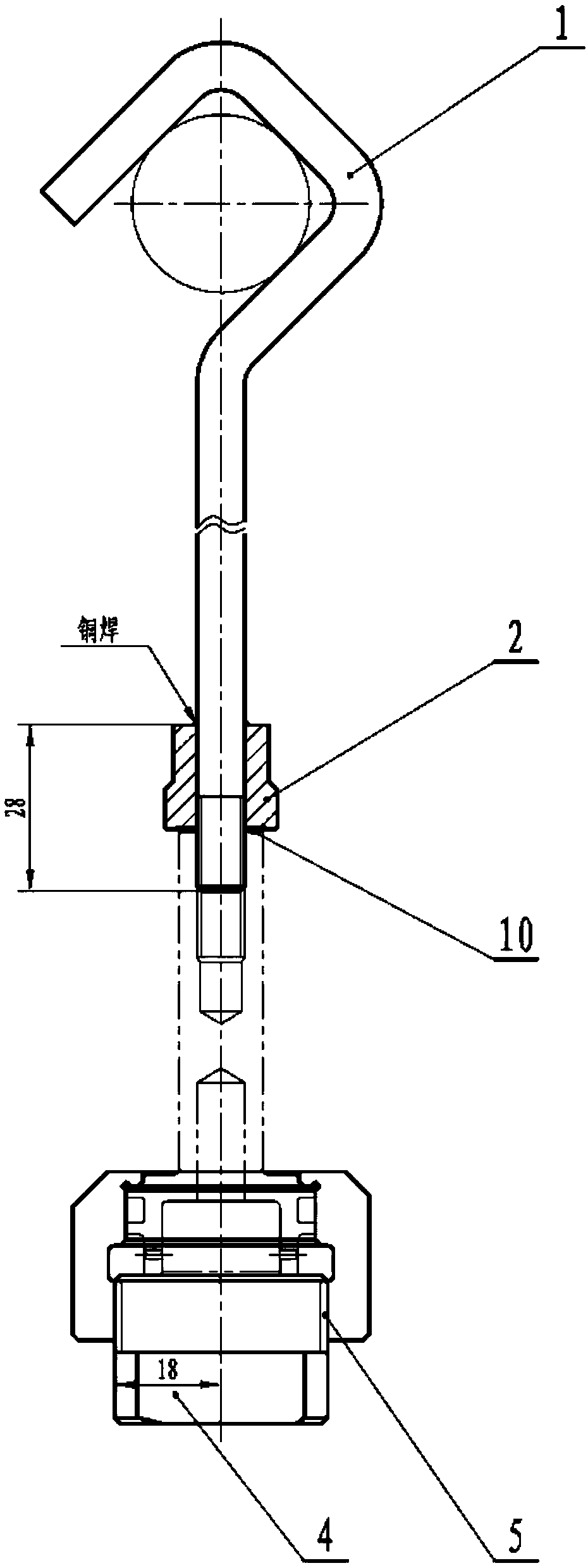

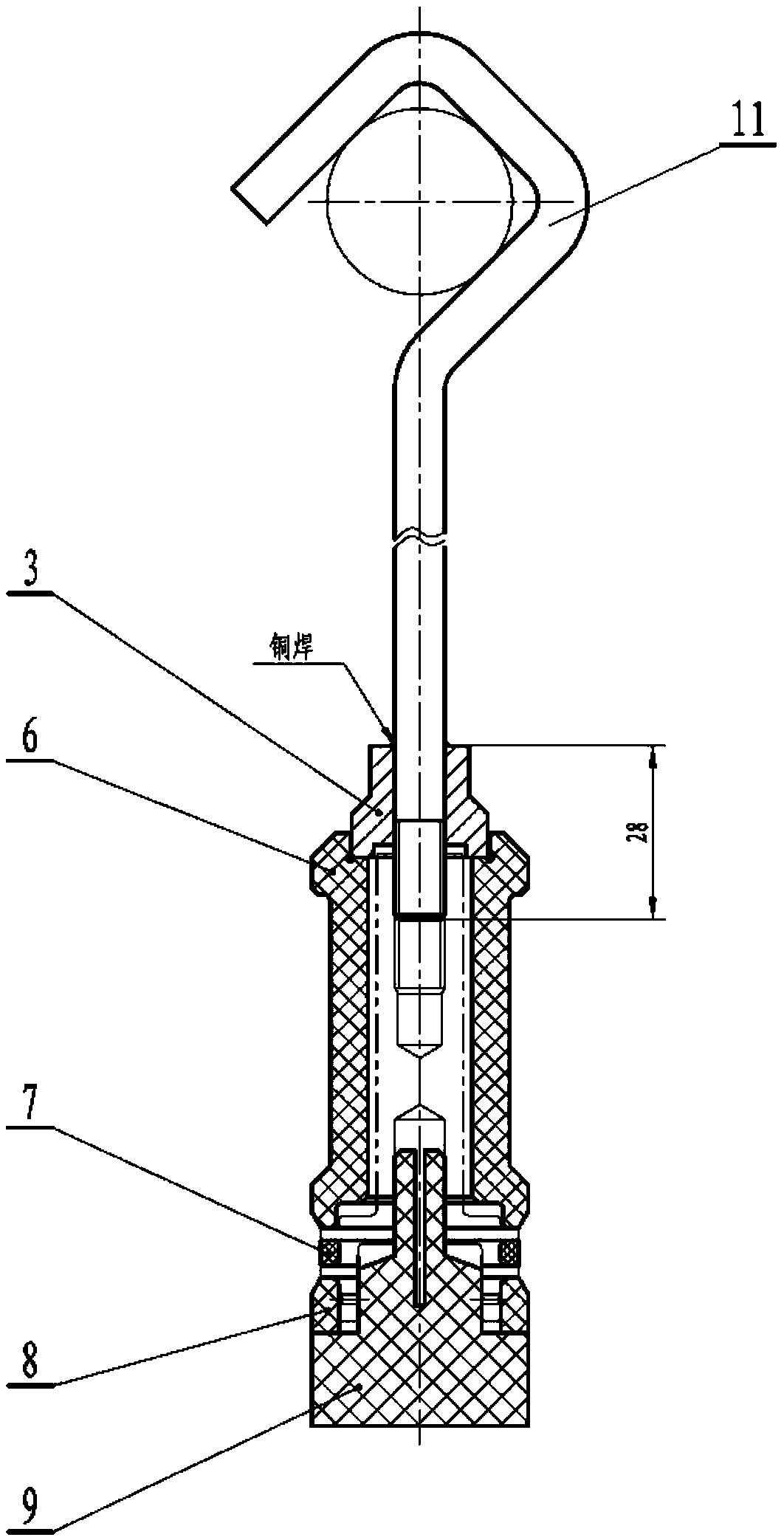

[0032] The chrome-plated assembly of the piston ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com