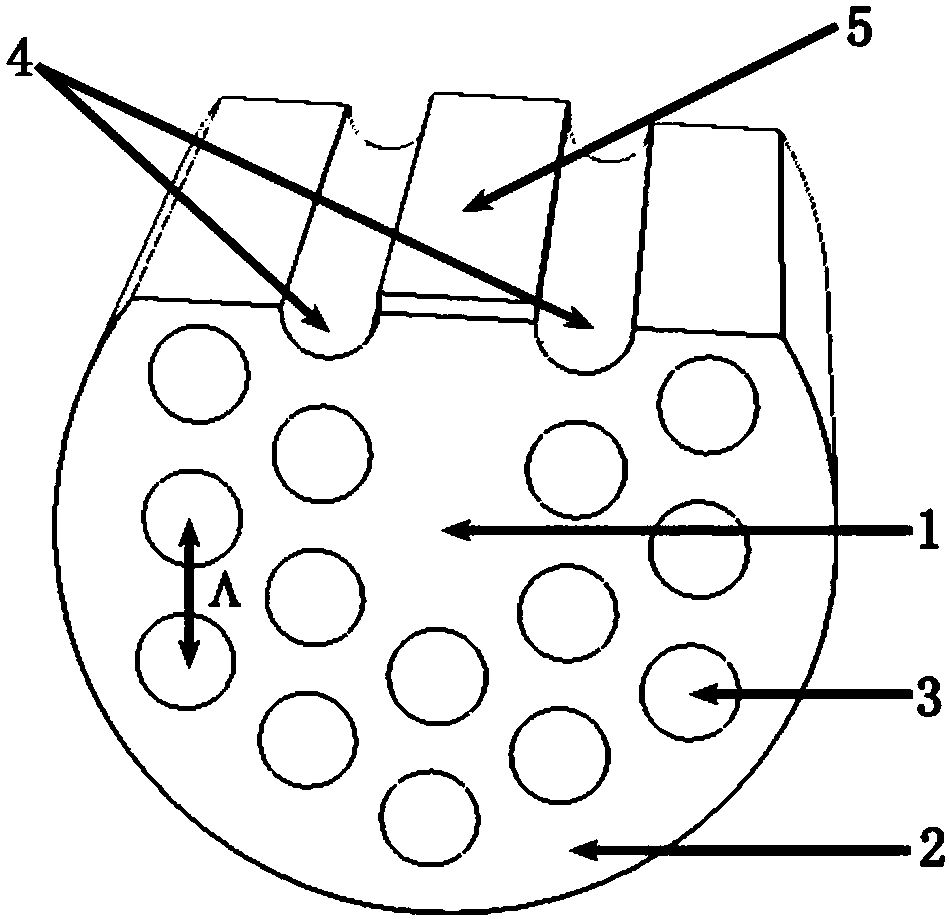

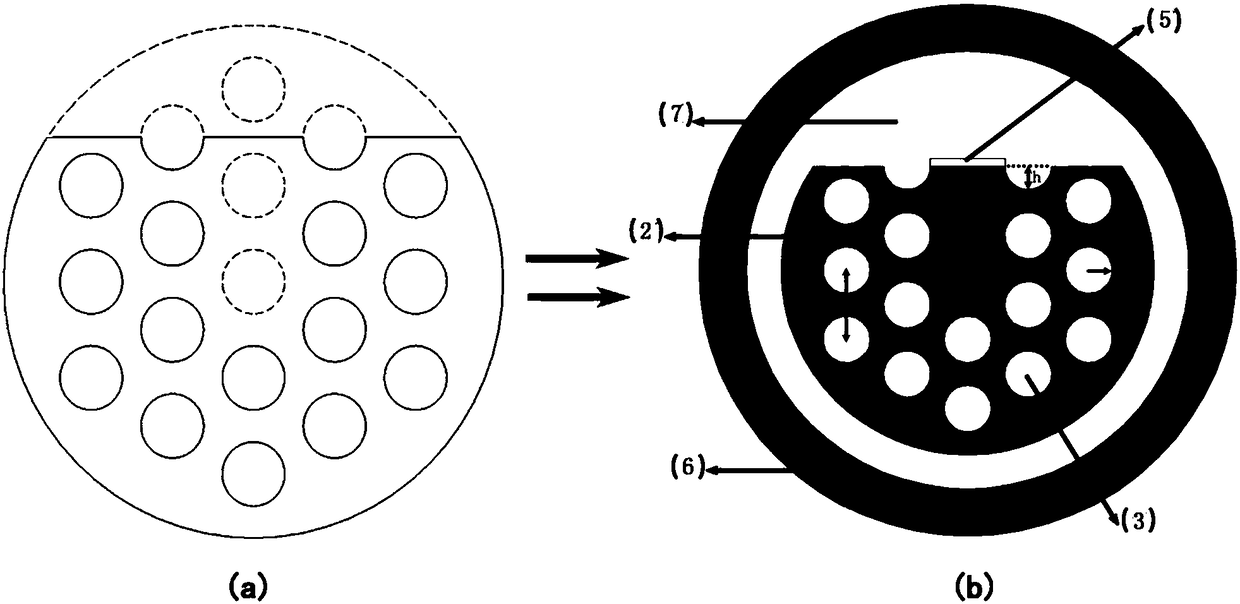

Microstructure optical fiber

A technology of micro-structured optical fiber and optical fiber, which is applied in the direction of material analysis, measuring devices, and instruments through optical means, which can solve the problems of low sensitivity of optical fiber sensor, many air holes in optical fiber, and difficulty in realization, etc. It is easy to achieve drawing parameters Simple control and crafting, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

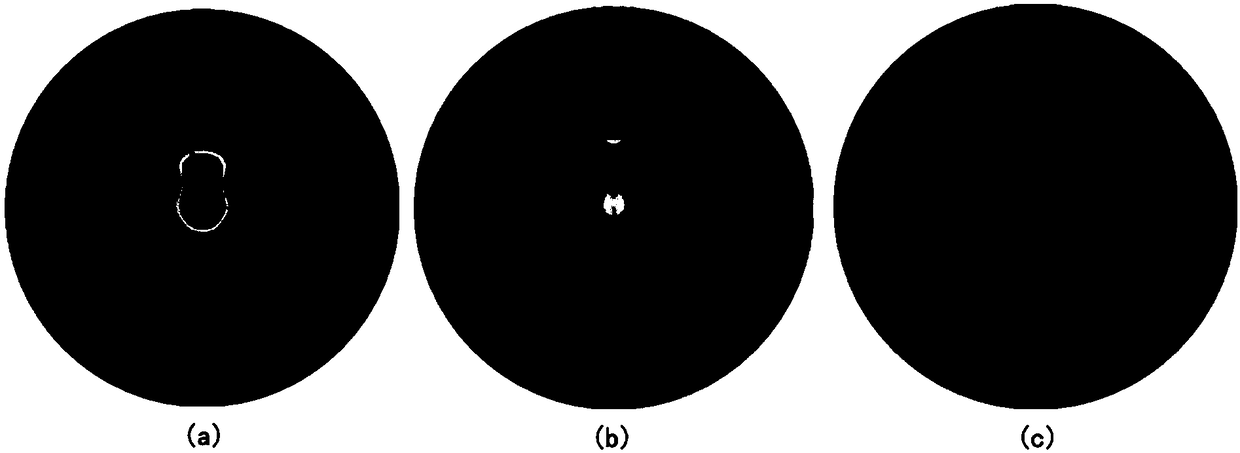

[0035] Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is that when the thickness of the gold film coated on the polished surface of the microstructured optical fiber is 30nm, the limiting loss of the microstructured optical fiber varies with the wavelength as follows: Figure 6 As shown, the refractive index range of different analytes to be measured here is 1.32-1.36. With the gradual increase of the refractive index of the analyte to be measured, the resonance peak in the y-polarized core conduction mode gradually red-shifted and the loss peak intensity gradually decreased, indicating that the surface plasmon resonance intensity gradually weakened. The range of resonance wavelength is 1660-1930nm (near infrared band). allowable Figure 6 It is obtained that when the refractive index changes from 1.35 to 1.36, the maximum resonance peak shift is 90nm, and the corresponding sensitivity is as high as 9000nm / RIU.

[0036] exist Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com