Patents

Literature

34results about How to "Good proportion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

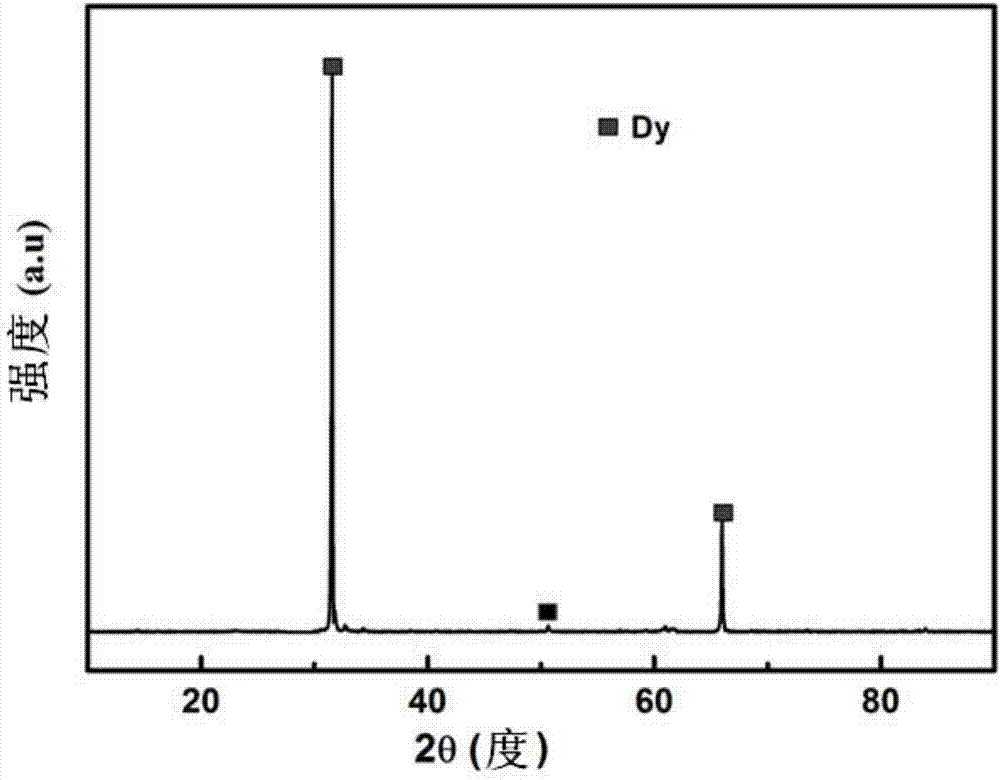

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

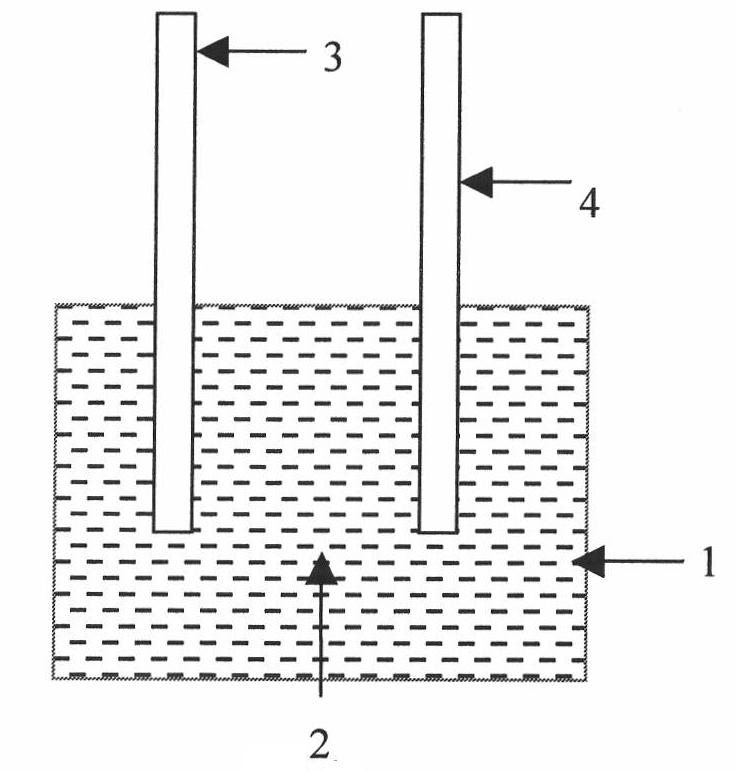

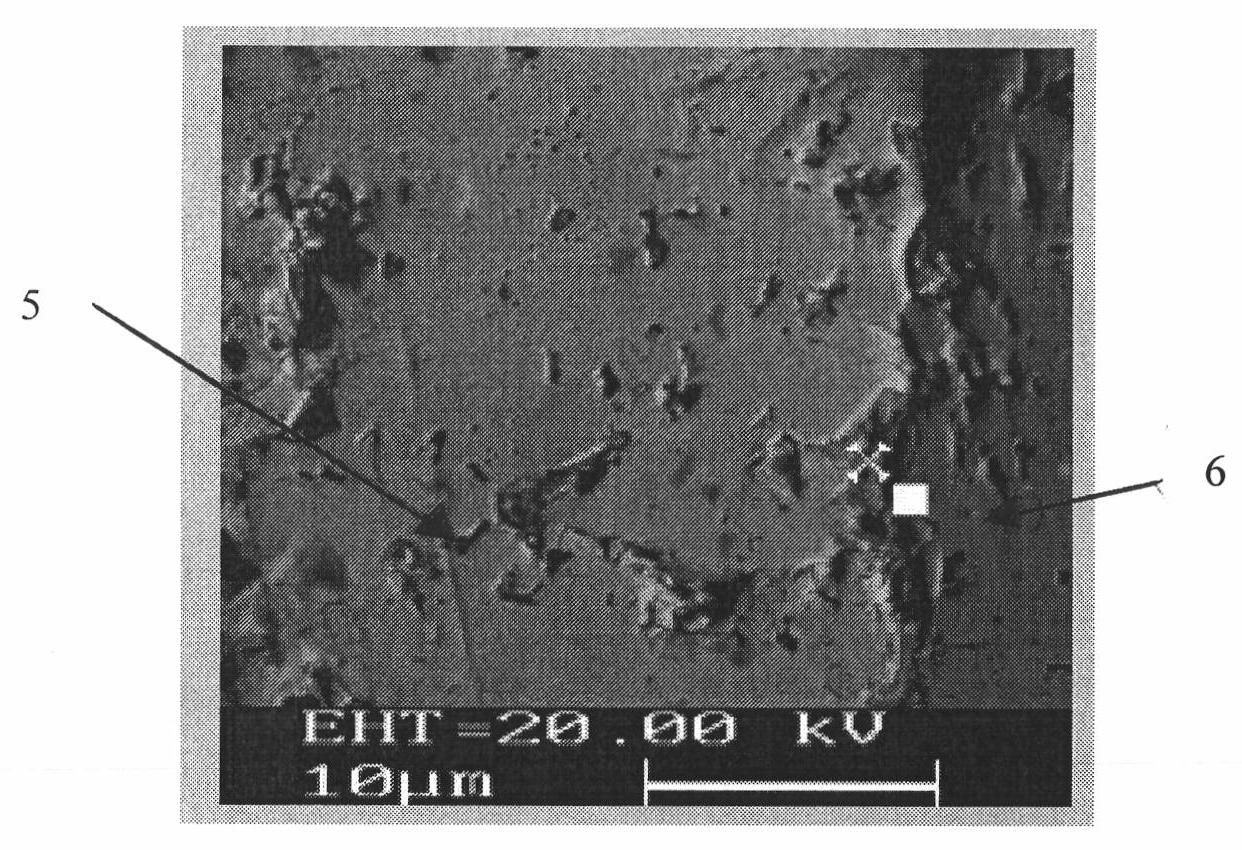

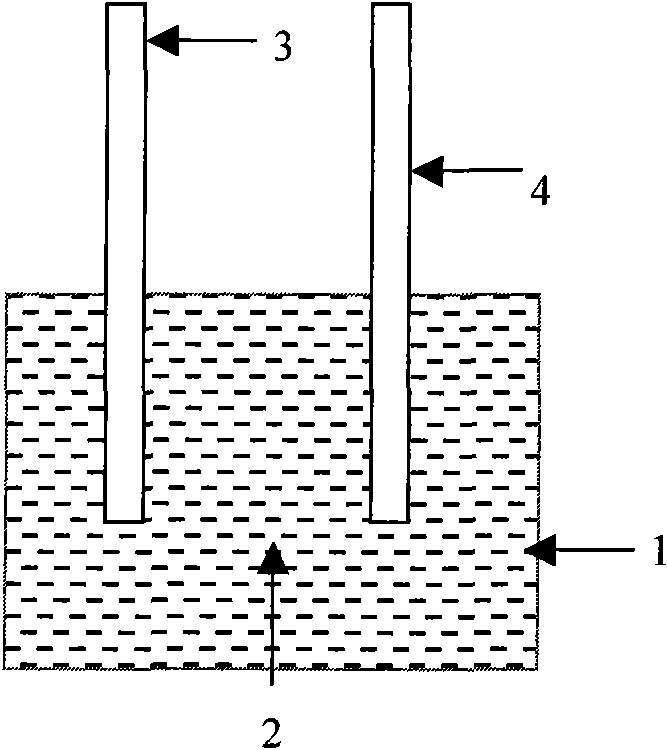

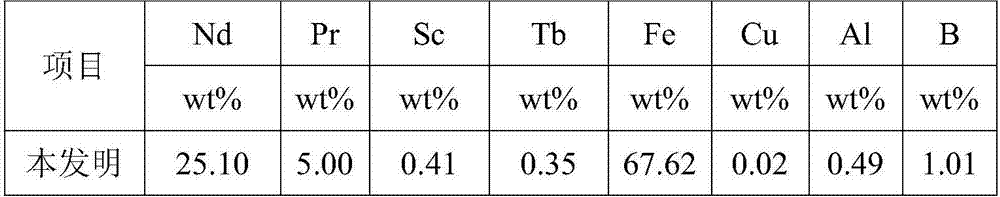

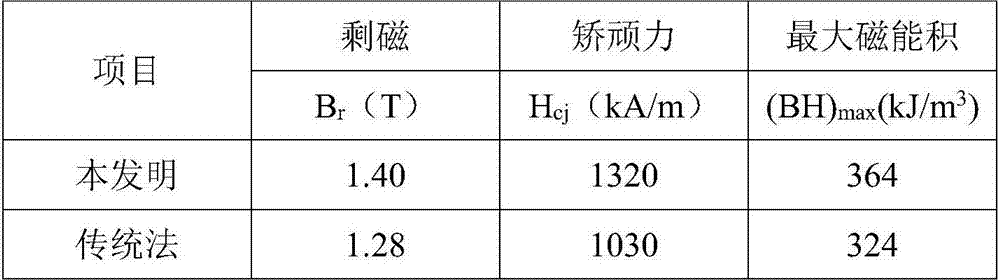

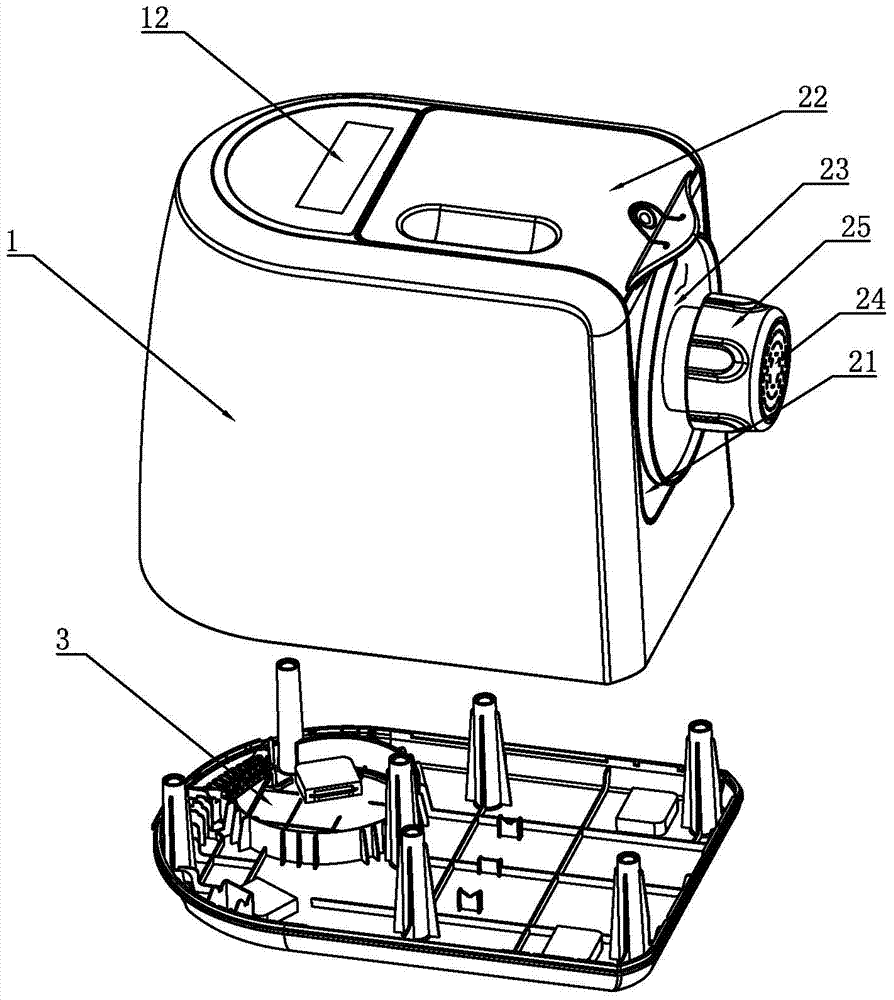

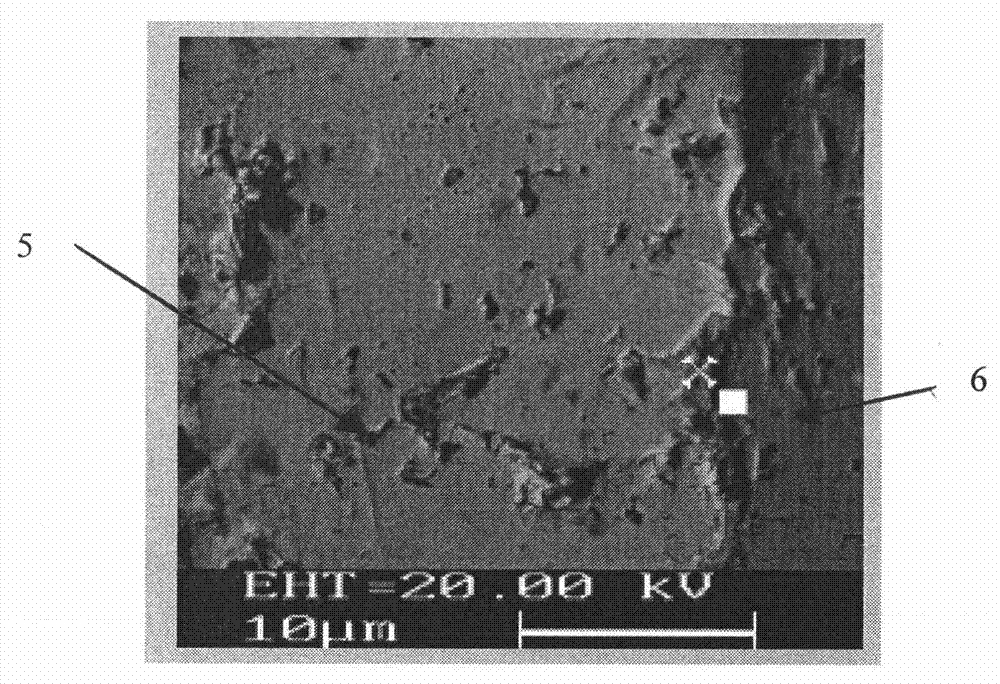

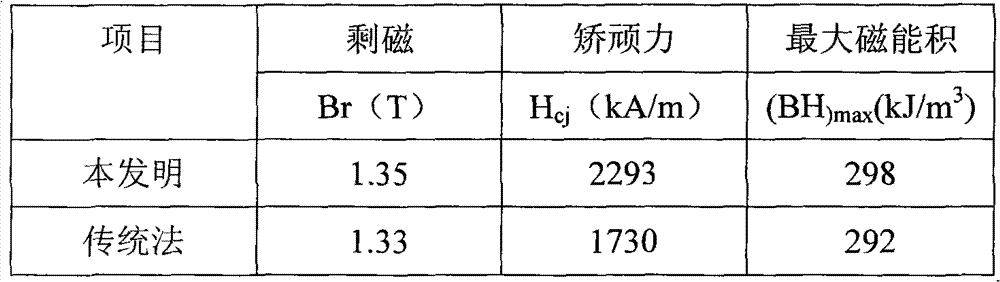

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

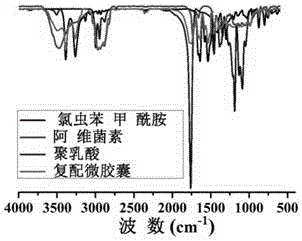

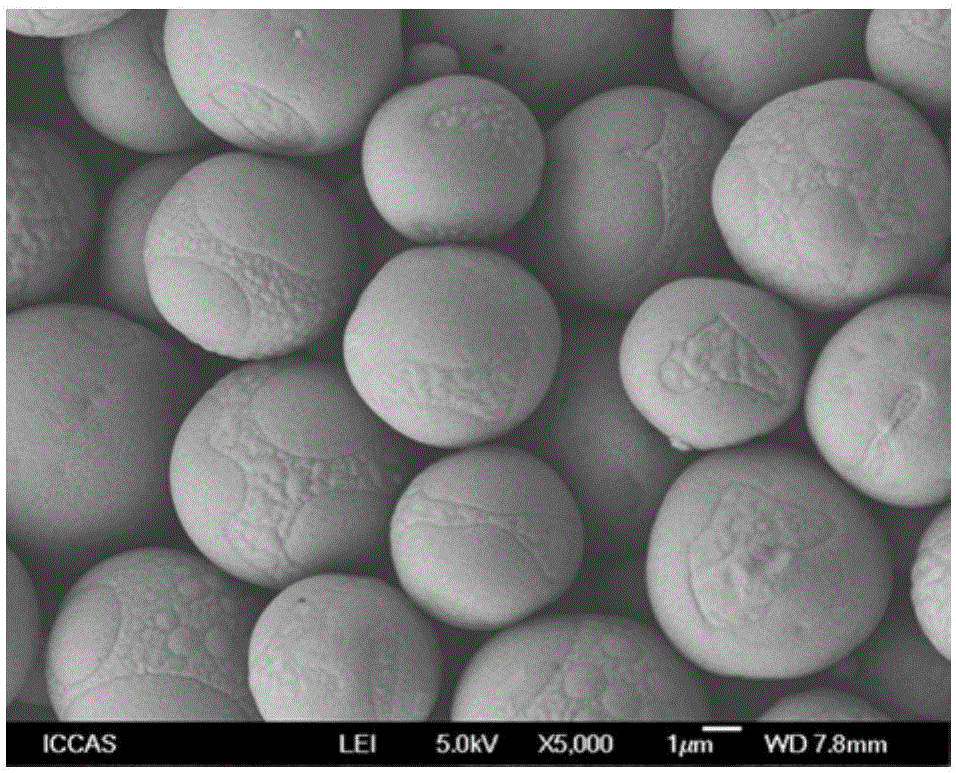

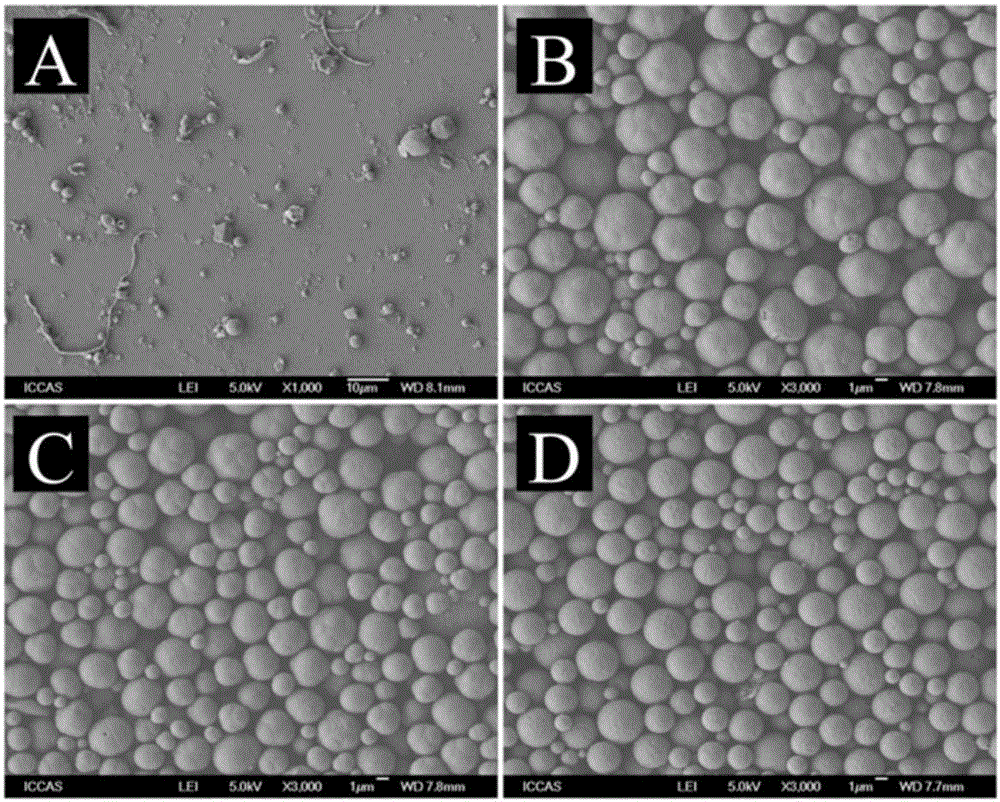

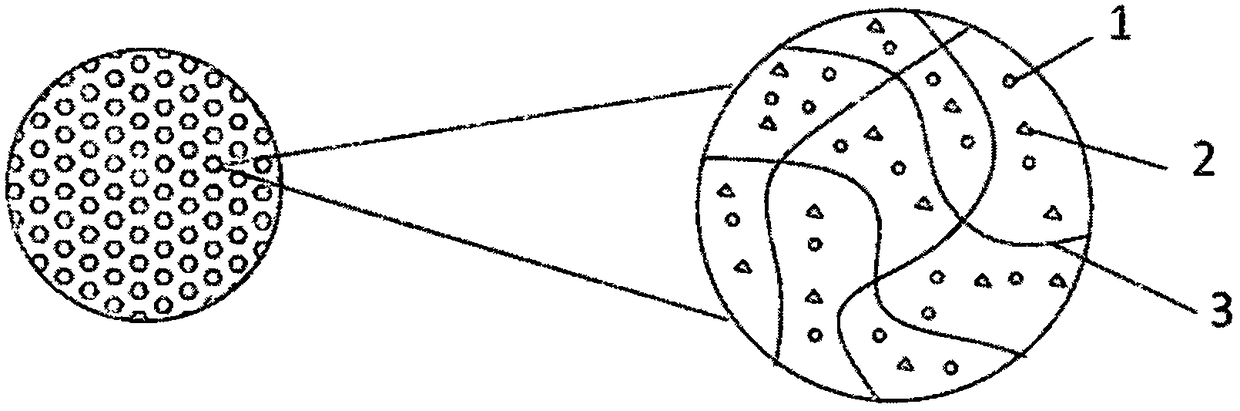

Capsule type compound pesticide formulation and preparation method and application thereof

InactiveCN106561644AAchieve insecticidal effectGood proportionBiocideDead animal preservationMolecular materialsCross-resistance

The invention discloses a capsule type compound pesticide formulation and a preparation method and application of the capsule type compound pesticide formulation. The compound pesticide microcapsule is composed of a shell, a pesticide A wrapped inside the shell and a pesticide B loaded in the shell. The shell is formed by a biodegradable high-molecular material. The pesticide A and the pesticide B do not have negative cross resistance or at least do not have cross resistance. According to the capsule type compound pesticide formulation, the manner that the kernel and the shell load pesticide is adopted to achieve compounding of the pesticides, and the ratio between the two compounded pesticides can be adjusted by adjustment of process parameters.

Owner:INST OF CHEM CHINESE ACAD OF SCI

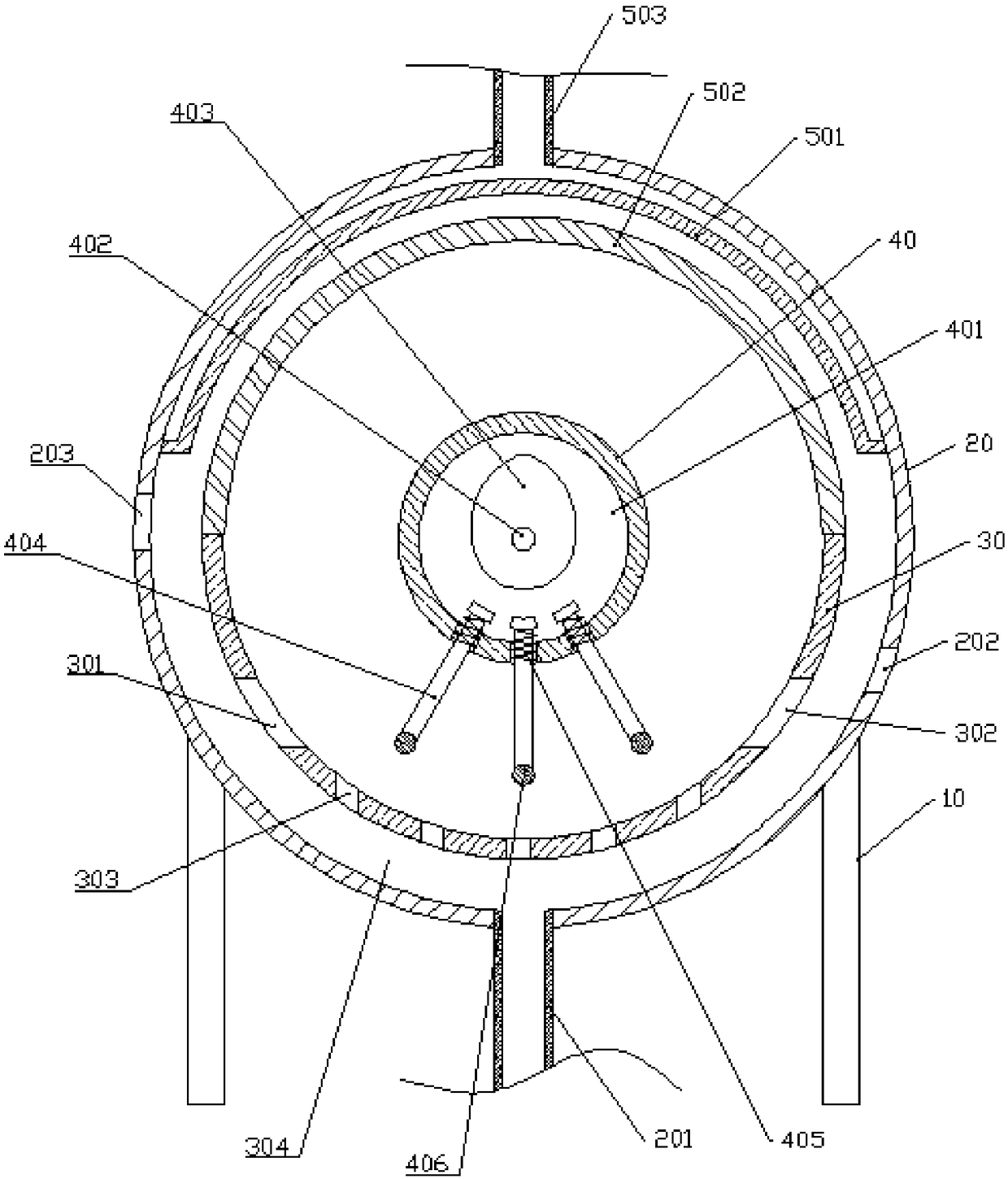

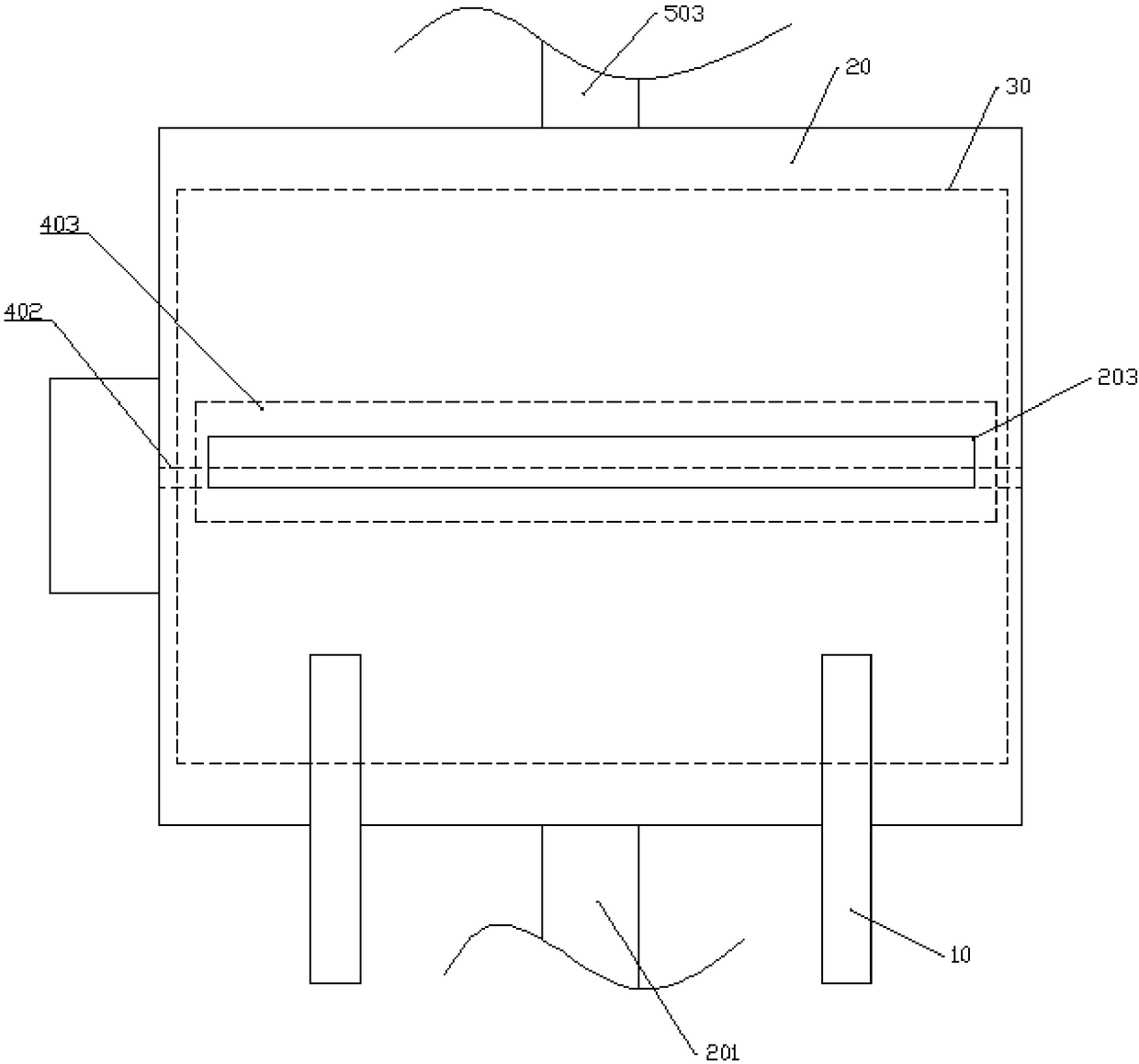

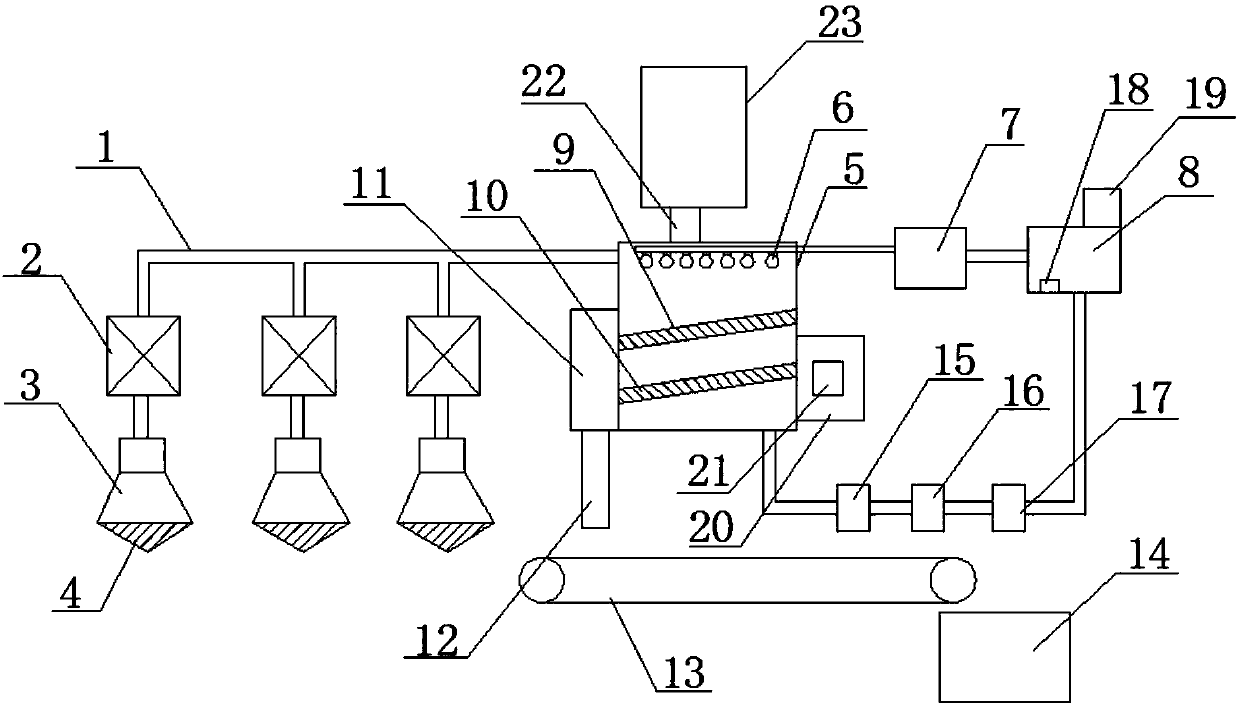

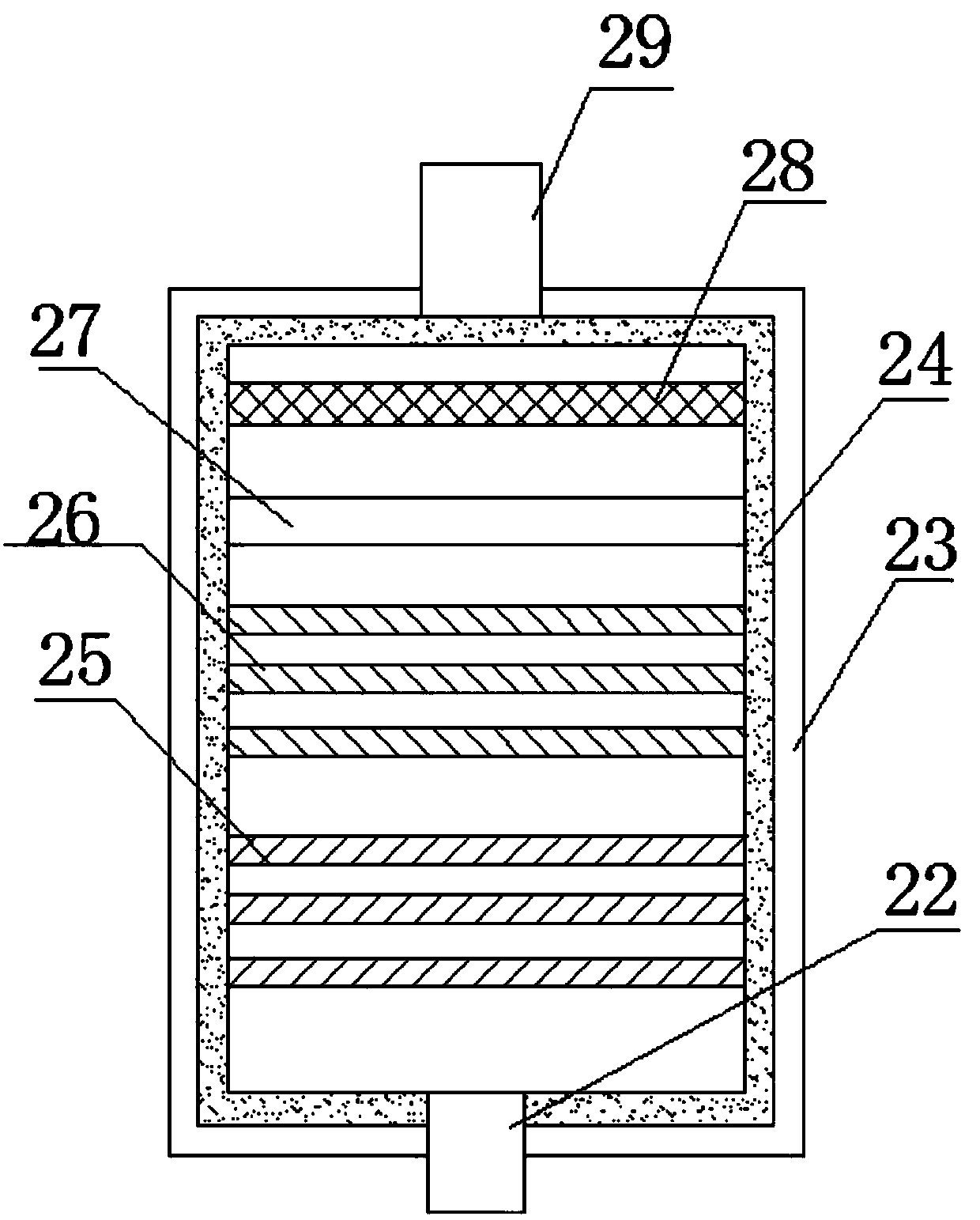

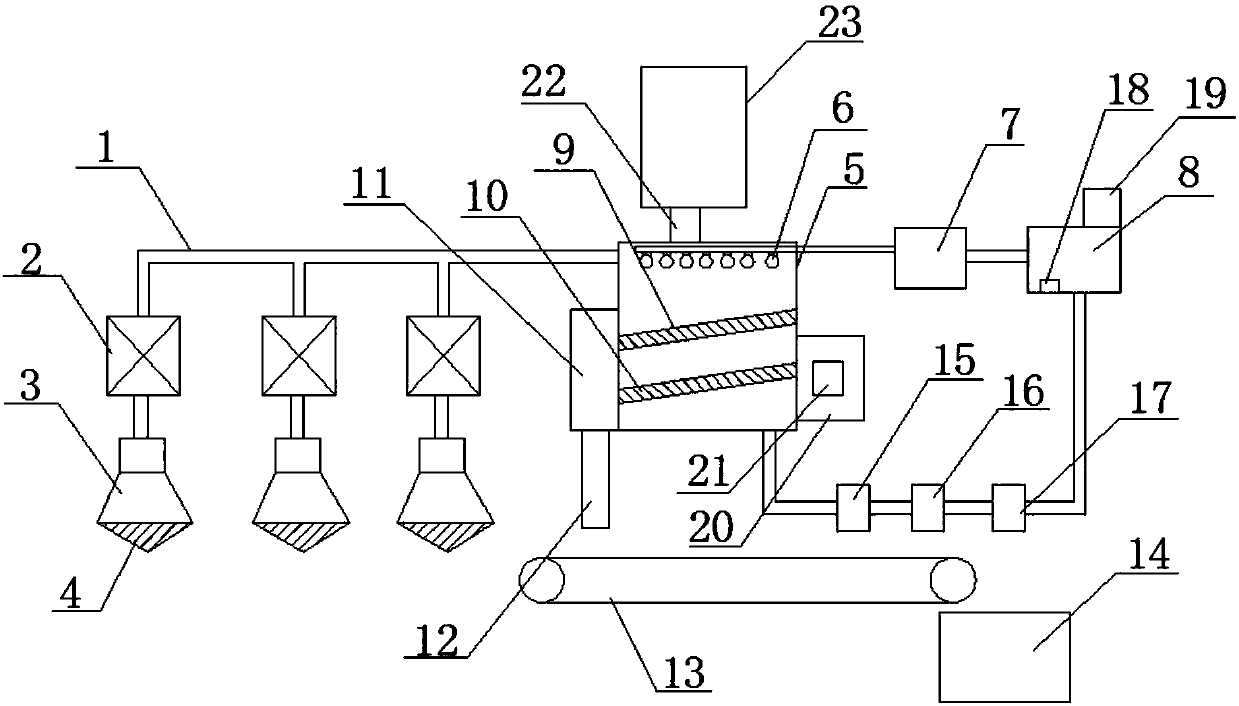

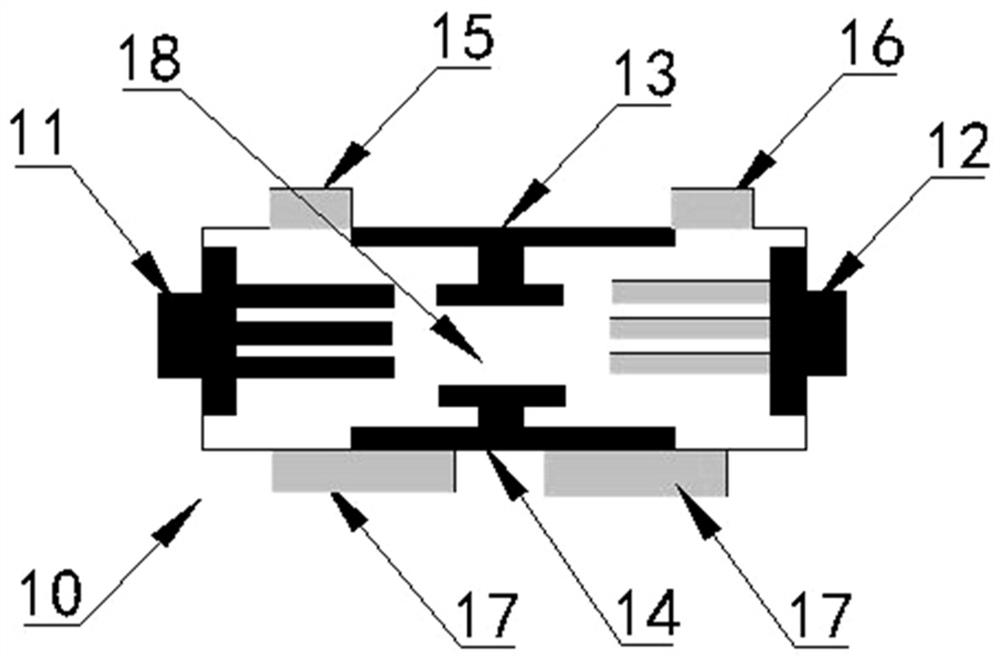

Dyeing method for cloth

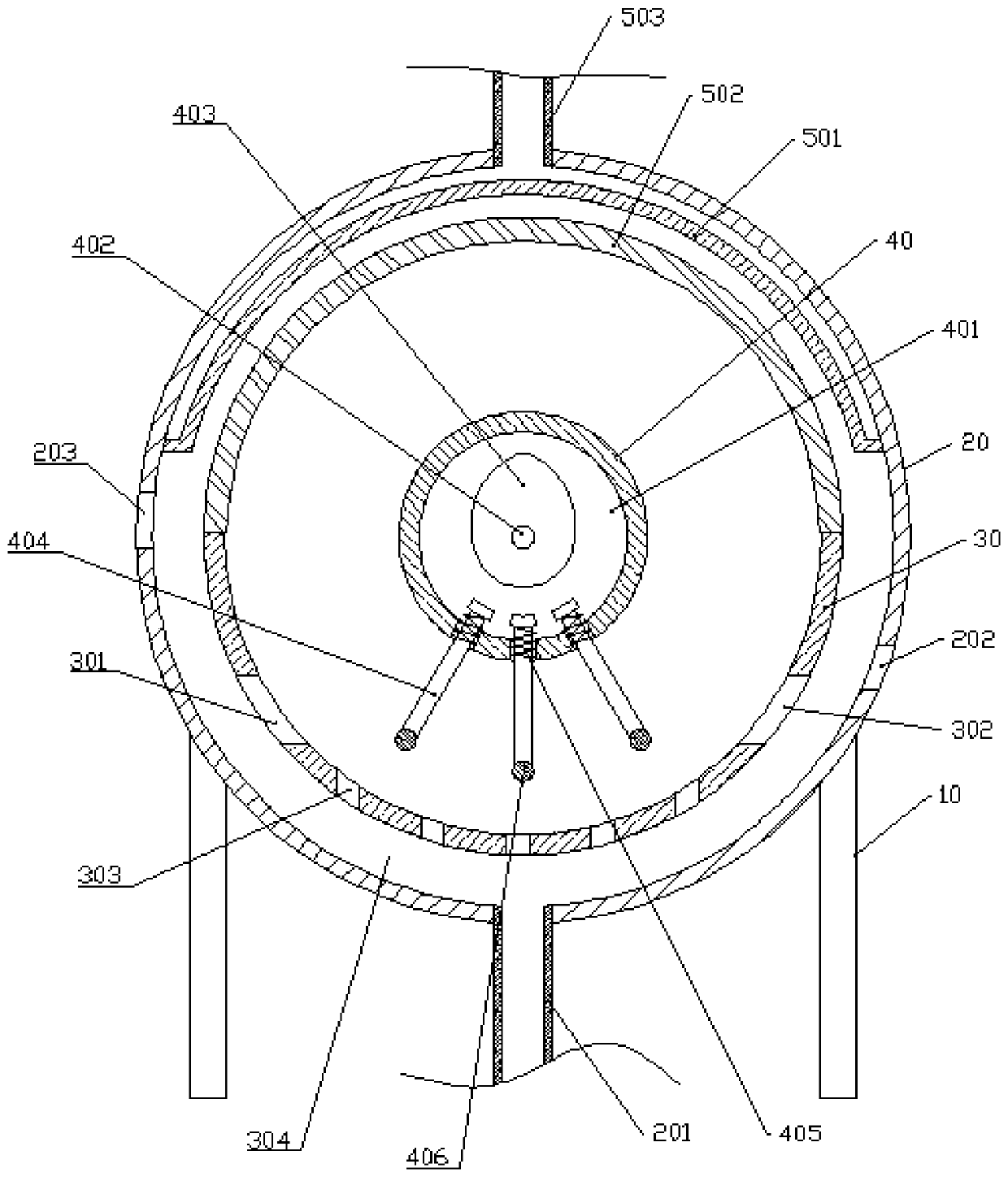

ActiveCN108179573AReduce processing stepsStrong dipping abilityLiquid/gas/vapor removalLiquid/gas/vapor fabric treatmentDyeingEngineering

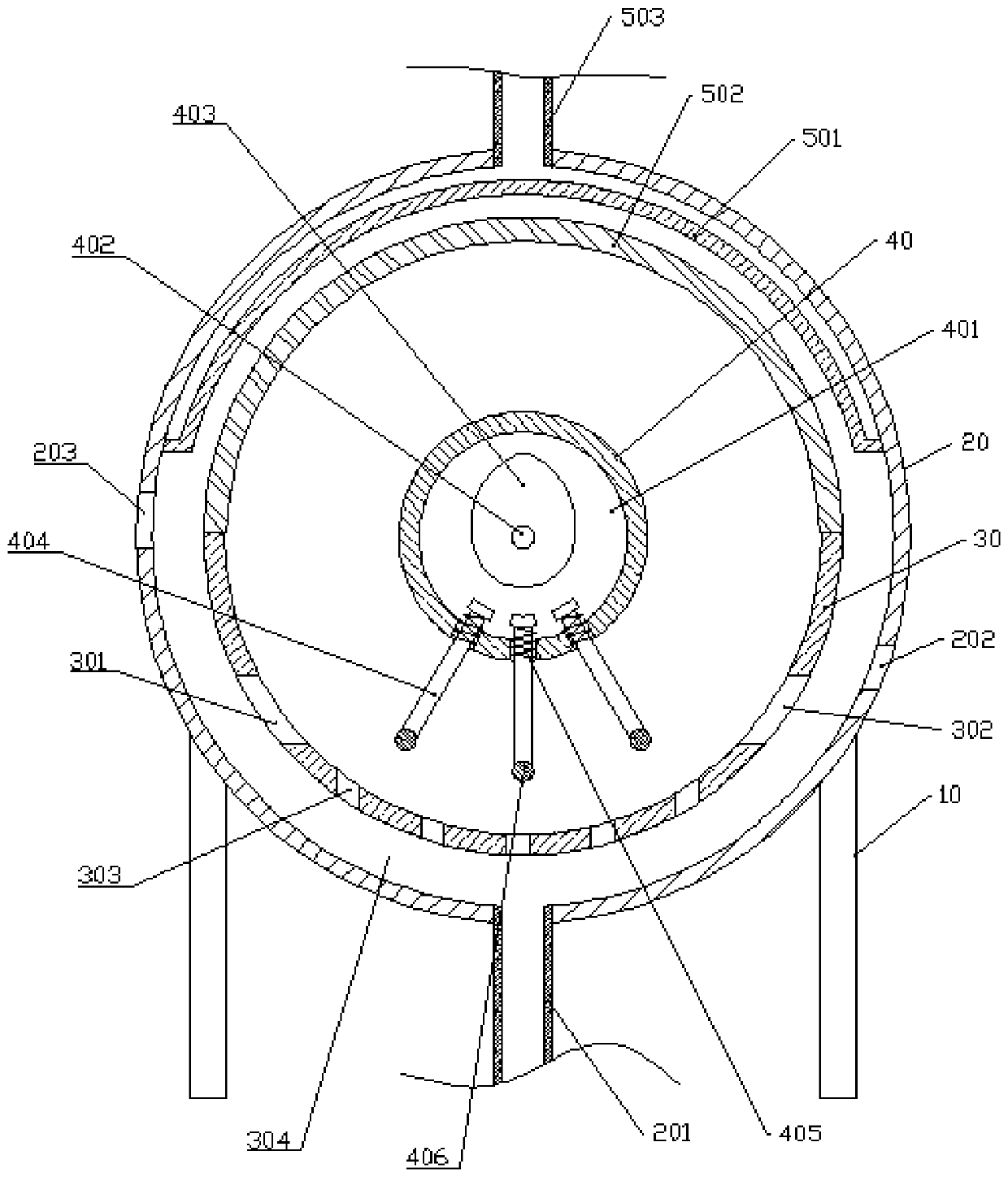

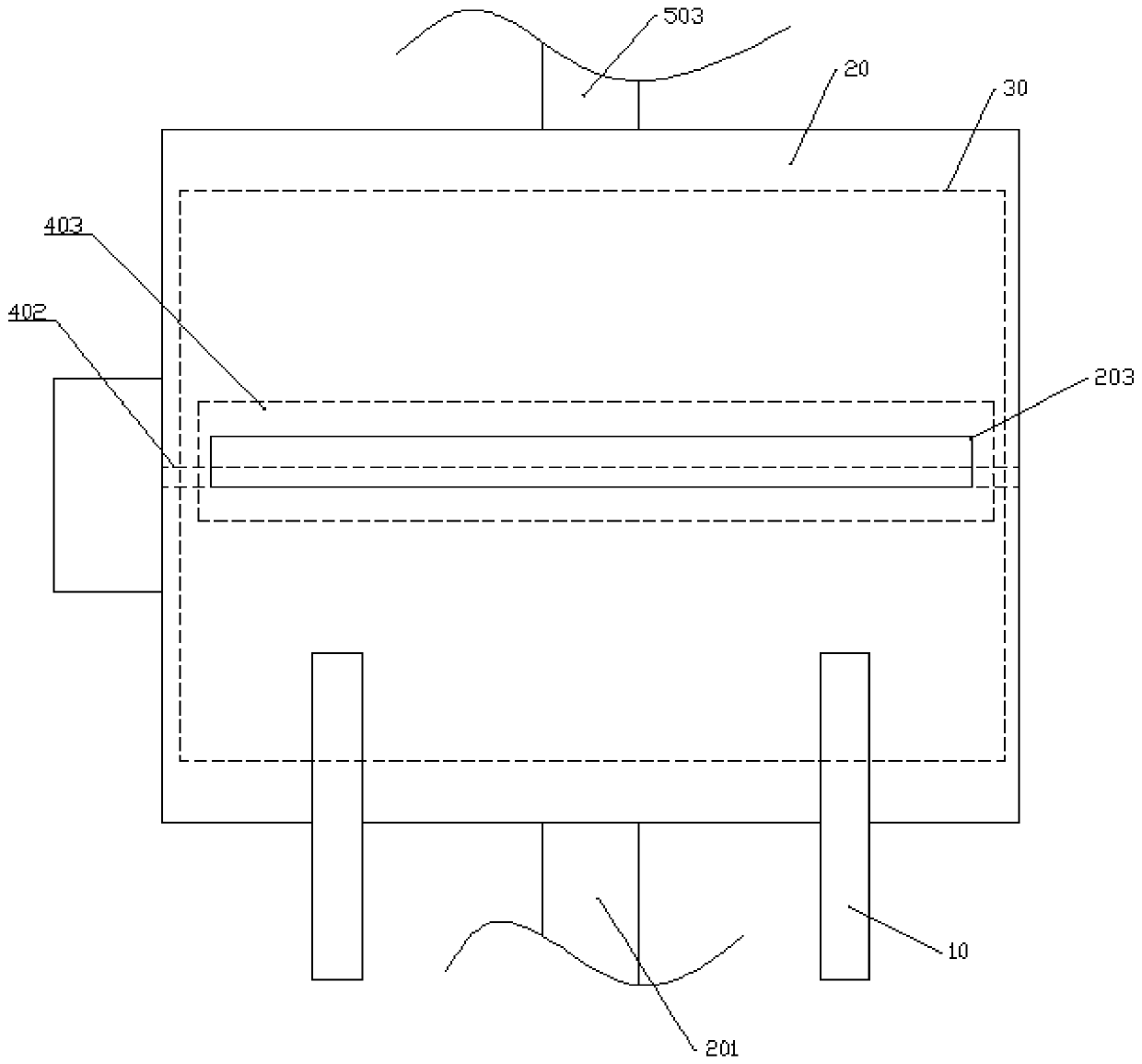

The invention relates to the field of cloth processing, and discloses a dyeing method for cloth. The method comprises the steps that dye raw materials are prepared; an unwinding roll, a winding roll,an outer tube, an inner tube, a drying mechanism and a water inlet pipe are prepared; dye B is prepared; gray cloth is coaxially installed on the unwinding roll, and one end of the gray cloth penetrates through a second inlet, a dye cavity, a first inlet, a first outlet and a second outlet in sequence and then fixedly connected to the surface of the winding roll; meanwhile, and the dye B is pouredinto the dye cavity through the water inlet pipe; the winding roll rotates at the rotating speed being 10-20 r / min, at the moment, the gray cloth penetrates through the second inlet and is located atthe dye cavity, the dye B in the dye cavity dyes the gray cloth, and gray cloth A is obtained; the gray cloth A continues to move to pass through the first inlet and the first outlet and is located at the drying mechanism, the drying mechanism dries the gray cloth A, and gray cloth B is obtained, wherein the baking temperature of the drying mechanism on the gray cloth A is 100-200 DEG C; the graycloth B continues to move to pass through the second outlet and then is wound on the winding roll. Accordingly, corrugation generated on the cloth in the dyeing process can be avoided.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

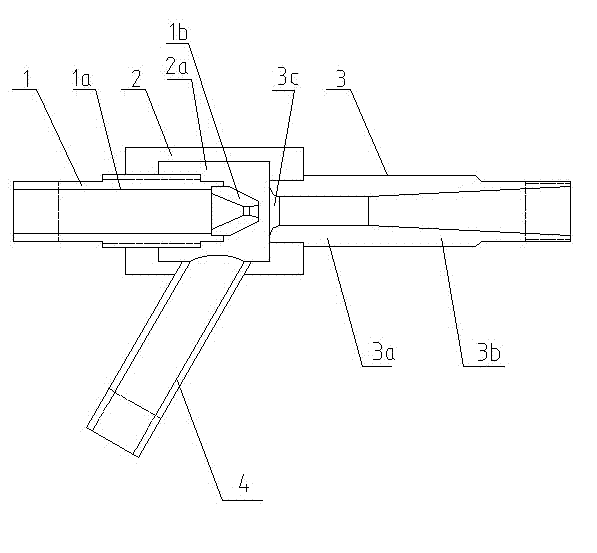

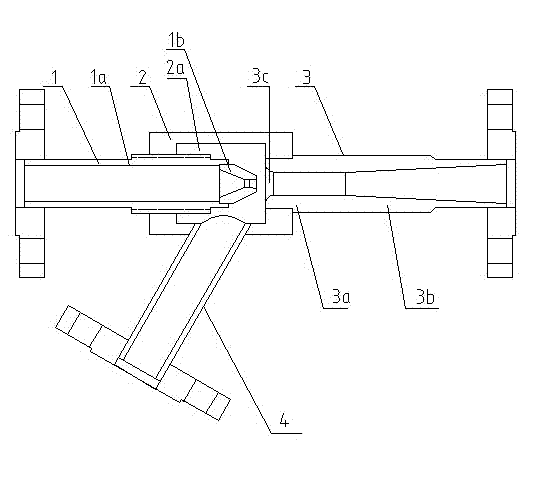

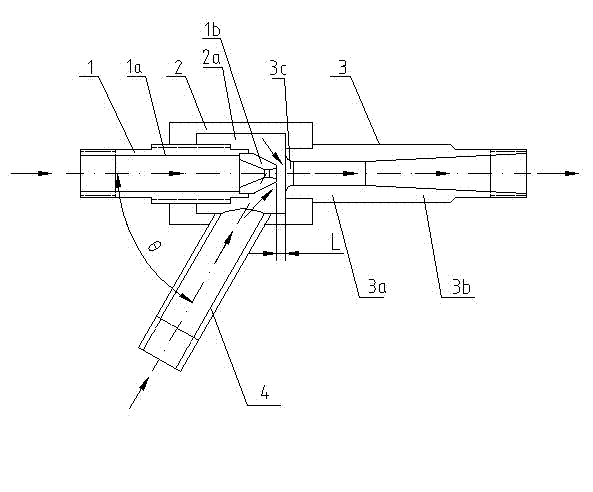

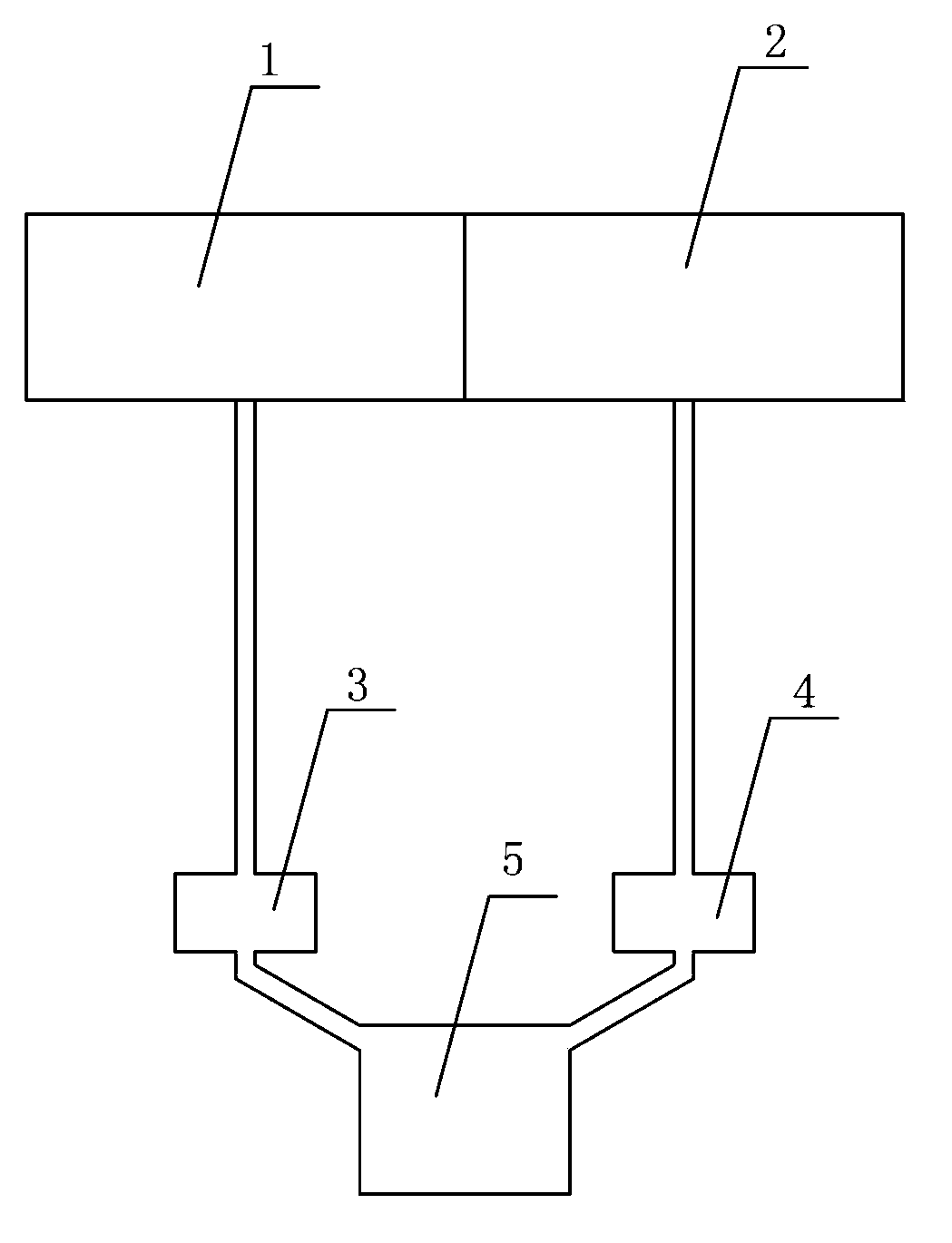

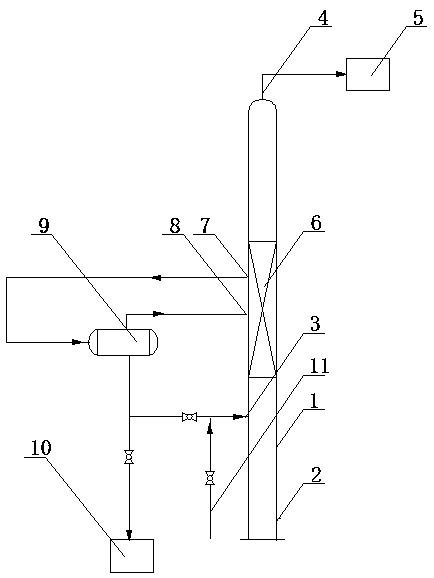

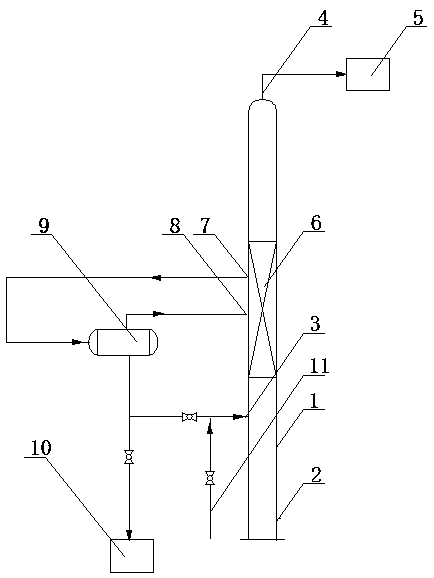

Gas liquid-pumping device

InactiveCN102654146AStrong conveying capacityEasy to useJet pumpsMachines/enginesSpray nozzleEnergy conservation

The invention relates to a gas liquid-pumping device, comprising a nozzle, a cylinder body, a diffusion pipe and a liquid-pumping pipe. A suction cavity is arranged in the cylinder body; the nozzle is arranged in the cylinder in a penetrating manner; the front end of the nozzle is located in the suction cavity, and the rear end of the nozzle is located outside the cylinder; the diffusion pipe is communicated with the cylinder body; the liquid-pumping pipe is communicated with the cylinder body; axes of the nozzle, the cylinder and the diffusion pipe are located on the same straight line; and the nozzle is connected with the cylinder body through threads. The gas liquid-pumping device has the advantages of green energy conservation, convenience in installation and use, simple structure, low maintenance cost, long service life, high security and reliability, large suction vacuum degree, and strong liquid delivery capacity.

Owner:ZHEJIANG HANGZHEN ENERGY TECH CO LTD

High-coercivity Nd-Fe-B rare-earth permanent magnet and fabrication process thereof

InactiveCN107993785AImprove uniformityFilm thickness controllableInorganic material magnetismPermanent magnet manufactureRare earthMagnetic energy

The invention provides a fabrication process of a high-coercivity Nd-Fe-B rare-earth permanent magnet. A technology of preparing a rare-earth thin film from an ion liquid is applied to fabricate a high-performance magnet, a Rb thin film is grown on a surface of the magnet by the technology, a Rb element plated on the surface of the magnet is diffused to the interior of the magnet by primary high-temperature thermal processing, a rare-earth rich phase is uniformly distributed around the magnet by secondary low-temperature tempering, and meanwhile, unbalanced tissue and internal stress brought by high-temperature processing are eliminated. The intrinsic coercivity of the magnet after being processed by the process can be obviously improved, so that the high-coercivity Nd-Fe-B rare-earth permanent magnet is fabricated. By the process, the production efficiency can be improved, the heavy rare-earth dosage during the fabrication process is reduced, and meanwhile, high coercivity is obtainedunder the condition that residual magnetism and magnetic energy product of the magnet are not reduced.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Corn multifunctional soil-improving and nutrient-control-released fertilizer and preparation method thereof

InactiveCN105237186AMeet the dosageIncrease productionClimate change adaptationAgriculture gas emission reductionControl releaseSoil properties

The invention relates to a corn multifunctional soil-improving and nutrient-control-released fertilizer, which comprises a biocarbon soil improving material and a chemical fertilizer according to a weight ratio of (13%-17%):(83%-87%). The fertilizer is prepared by combining the biocarbon soil improving material and the chemical fertilizer together according to the weight ratio mentioned above, thus the nutrients in chemical fertilizer can be fully utilized, at the same time, the soil can be improved, and the nutrients can be control-released. Moreover, the fertilizer can prominently increase the content of organic carbon in soil, improve the soil property, and reduce the releasing speed of nutrients, thus the happening rate of farmland pollution is reduced, the nutrient utilization rate is improved, the crop output and the income of farmers are increased, and the effect on corns is the most prominent.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

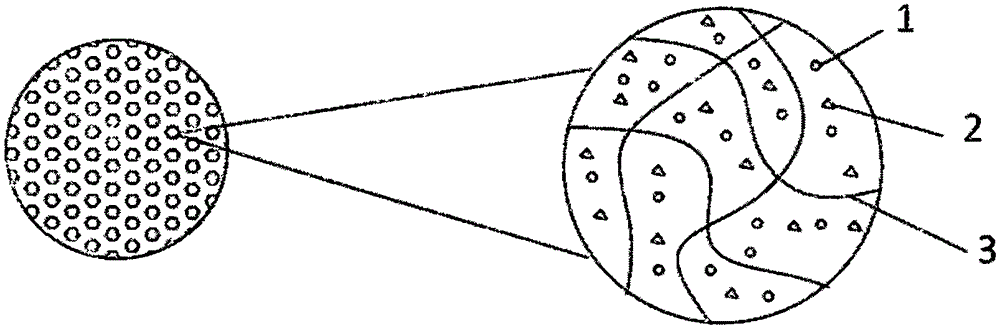

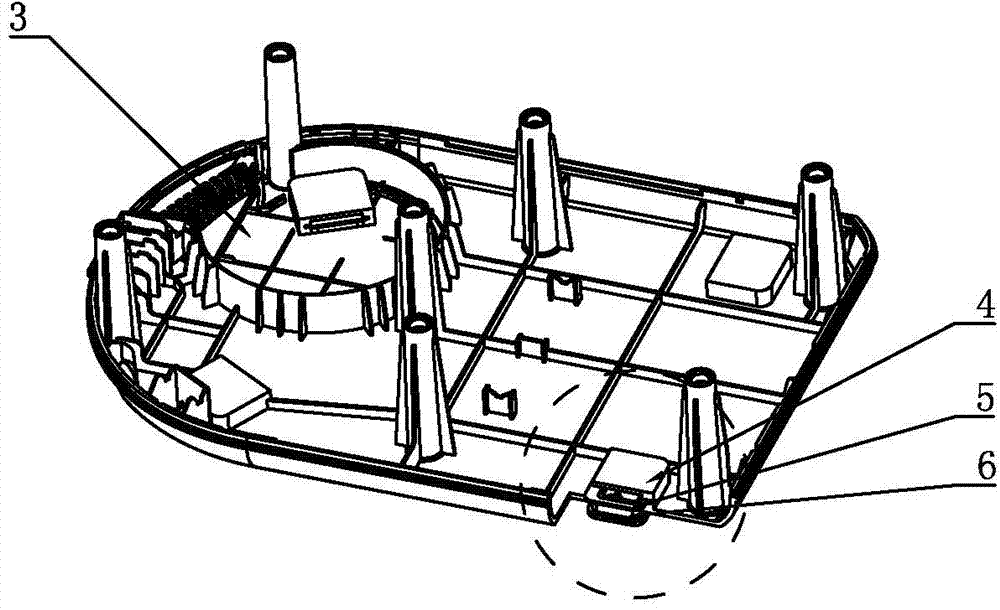

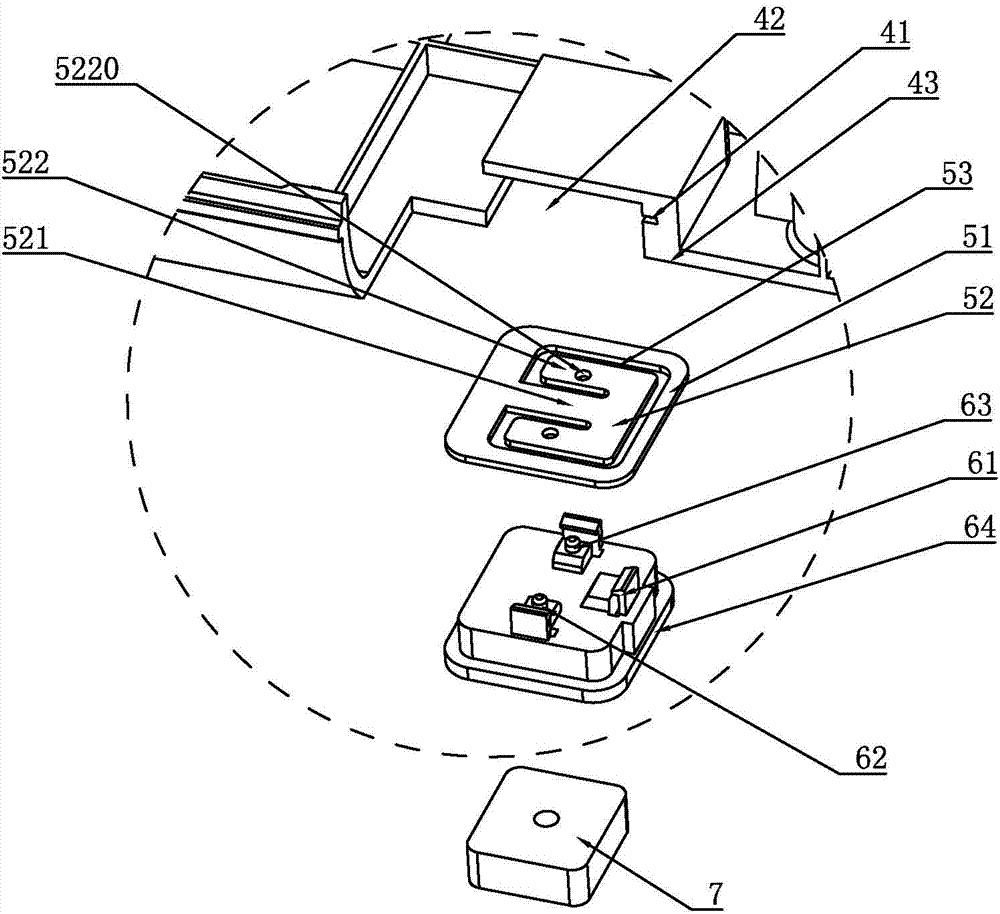

Noodle maker convenient for operation, detection method of noodle maker and processing method of noodle maker

ActiveCN104206466AAffect normal useEasy to operateMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsProcess engineeringIndustrial engineering

The invention discloses a noodle maker convenient for operation. The noodle maker comprises a base, a stirring cup connected to the base and an upper cover covering the stirring cup. The noodle maker is provided with a stirring assembly and a dough extrusion assembly. The noodle maker is characterized in that the noodle maker comprises a weighing unit and a control unit for controlling the weighing unit, the noodle maker is provided with a protection structure, the protection structure is arranged at the weighing unit, and a safe stroke of the protection structure is less than a safe stroke of the weighing unit. The existing noodle maker is provided with the weighing unit so that a user can accurately control use amounts of flour and a liquid and the noodle maker normal-use is not influenced by inappropriate operation through a user. The noodle maker provided by the invention is provided with the control unit so that corresponding liquid weight can be automatically calculated after flour addition and the noodle maker gives a liquid weight prompt for the user and thus use operation is simplified.

Owner:JOYOUNG CO LTD

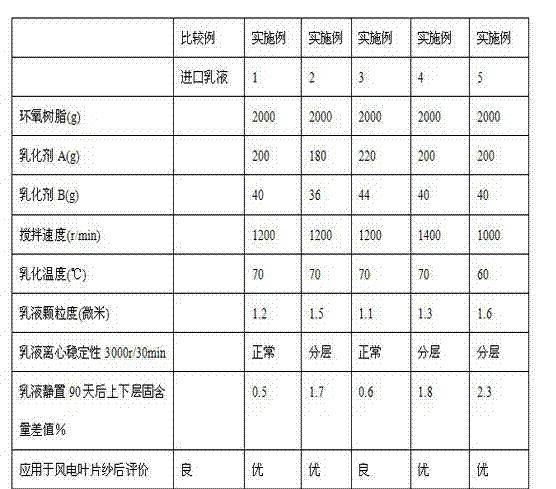

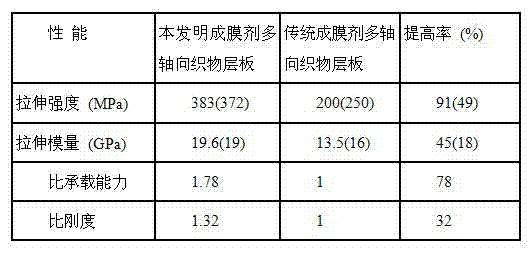

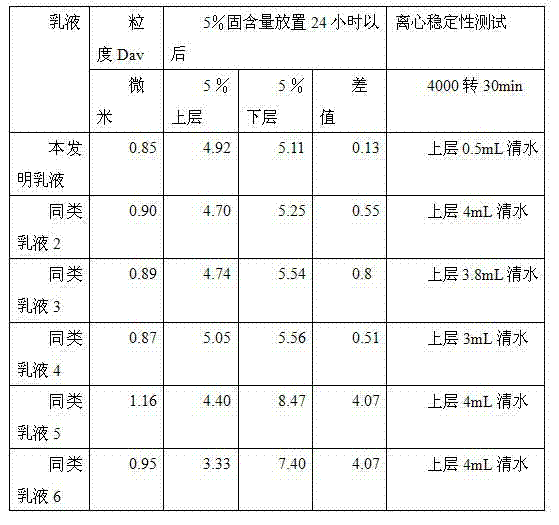

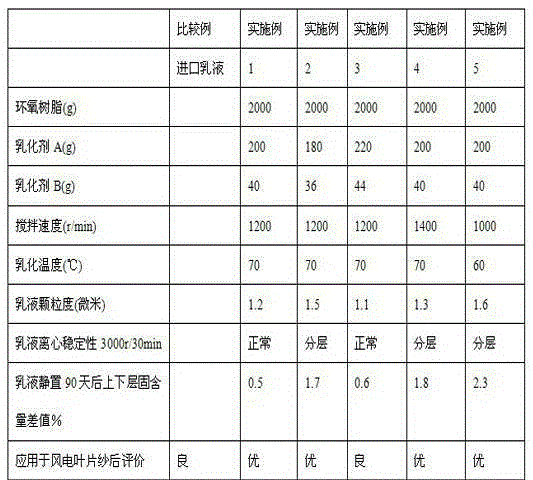

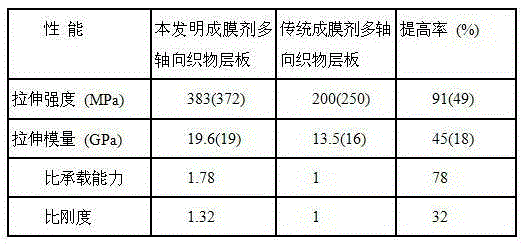

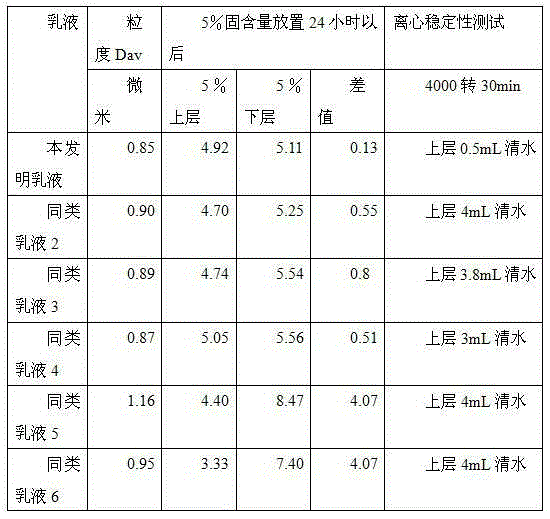

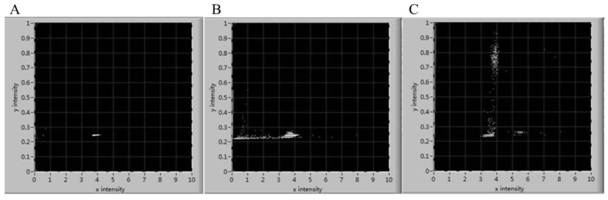

Special glass fiber film-forming agent for wind turbine blades and preparation method thereof

The invention relates to an epoxy resin compound aqueous emulsion and discloses an epoxy resin compound aqueous emulsion which can be used for manufacturing glass fiber film-forming agent for wind turbine blades. The glass fiber prepared by the aqueous emulsion, being used as the film-forming agent, is particularly suitable for the preparation of the wind turbine blades, and the aqueous emulsion does not contain VOC (volatile organic compounds) and nonyl phenols surface active agents, thus the aqueous emulsion has good safety and environment-friendly performances. The epoxy resin compound aqueous emulsion is characterized in that the aqueous emulsion can be used as the film-forming agent to draw glass fiber for manufacturing the wind turbine blades, all the indications including the penetration velocity, the composite material performance and the like; the aqueous emulsion is well in storage stability and use stability and is safe and environment-friendly. The aqueous emulsion mainly comprises epoxy resin, an emulsifying agent and deionized water. The epoxy resin aqueous emulsion provided by the invention can be used for large-scale wiredrawing work by a tank furnace method, thus the process is stable and the manufacturing cost is low.

Owner:TAISHAN FIBERGLASS INC

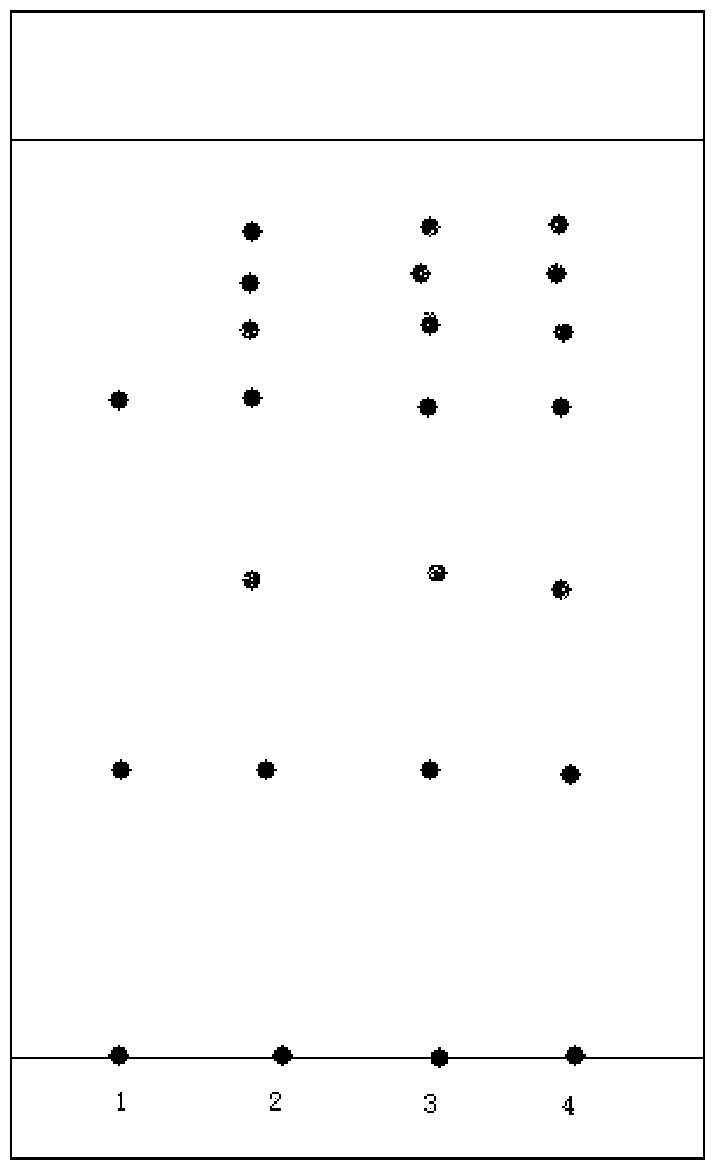

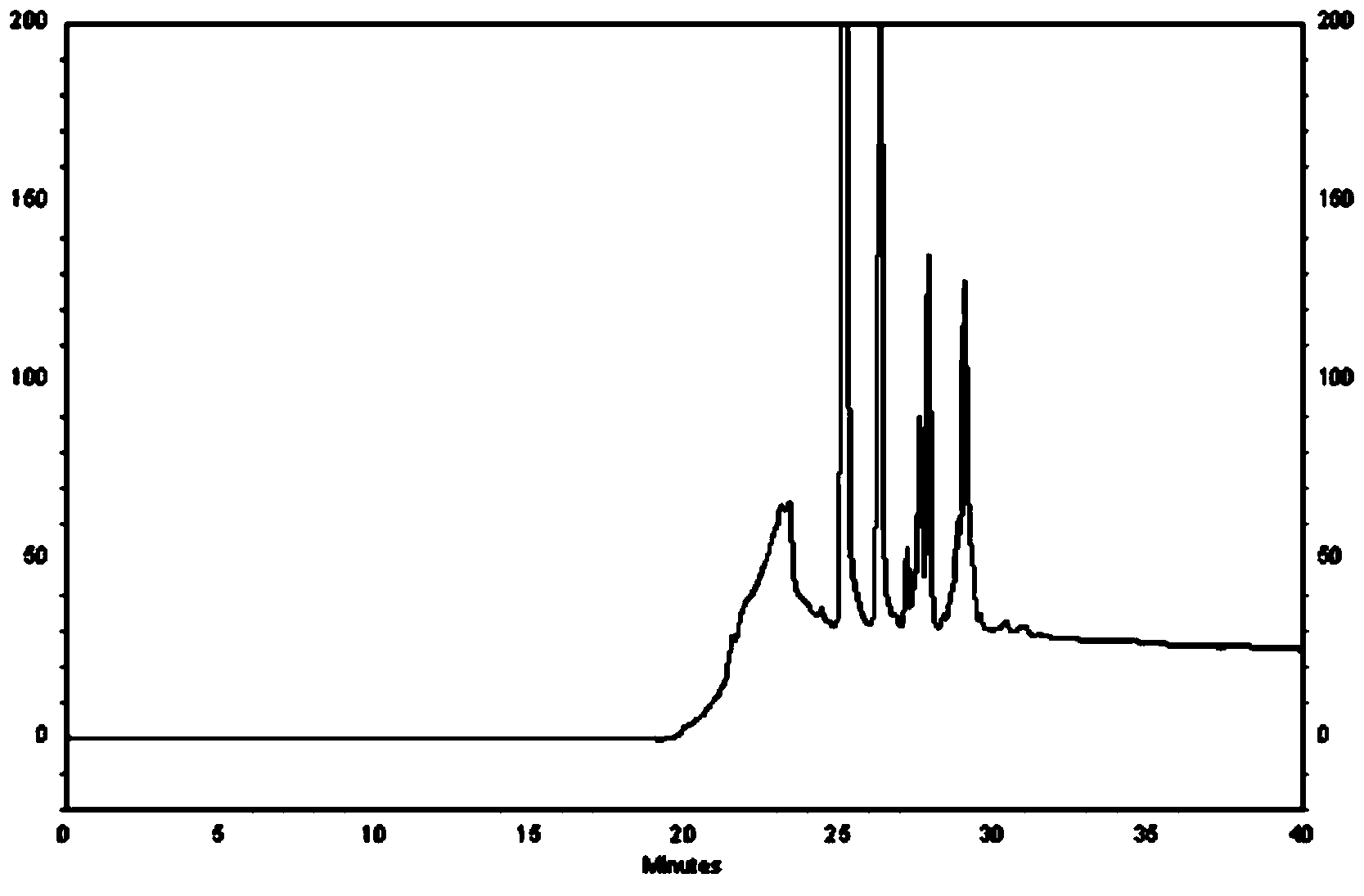

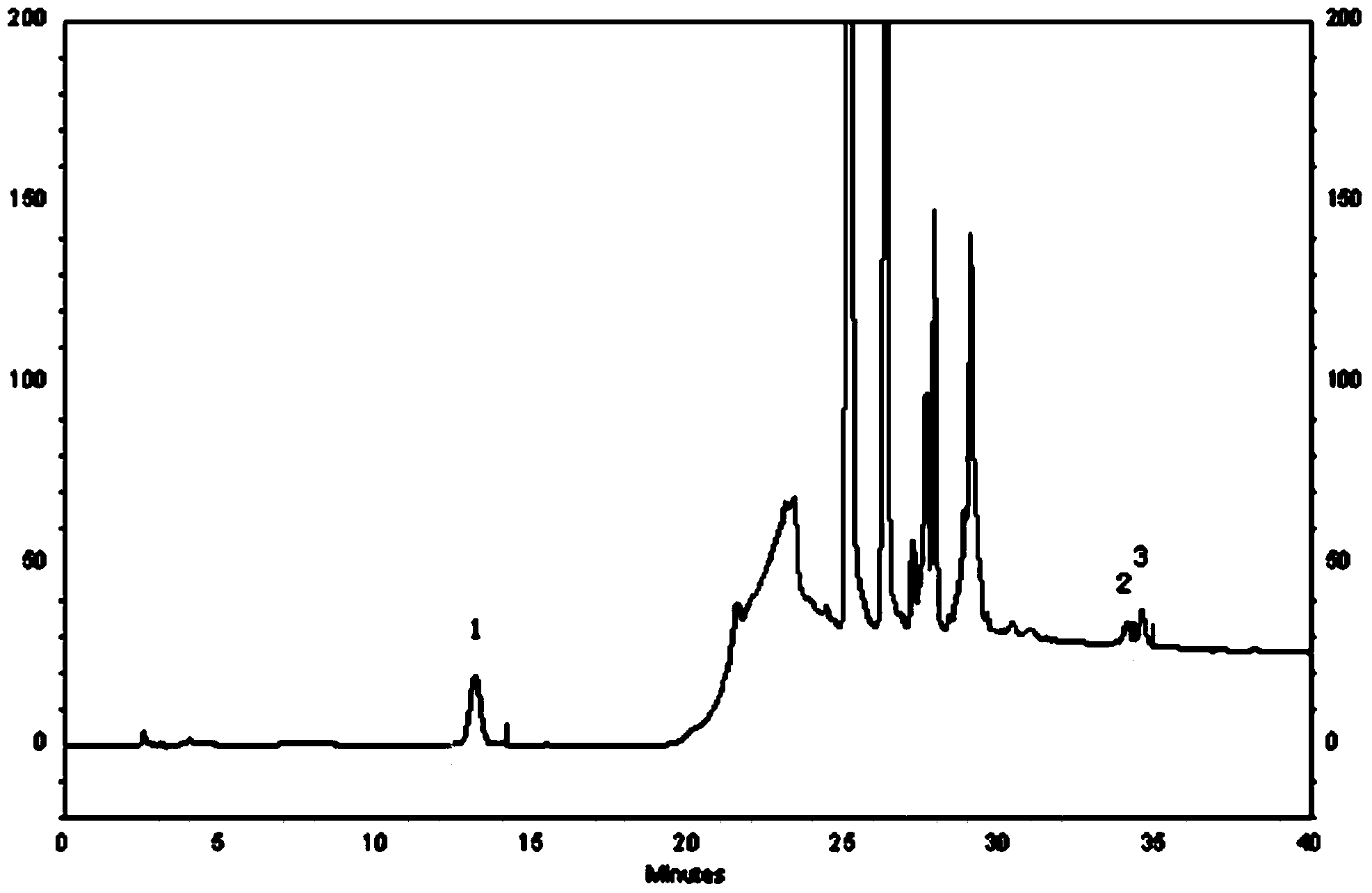

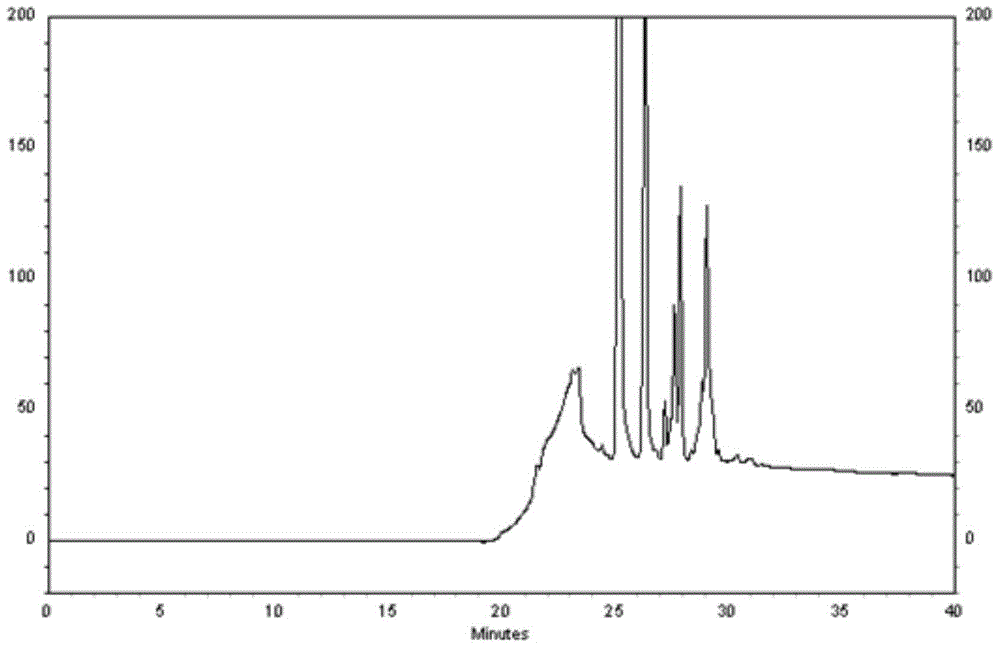

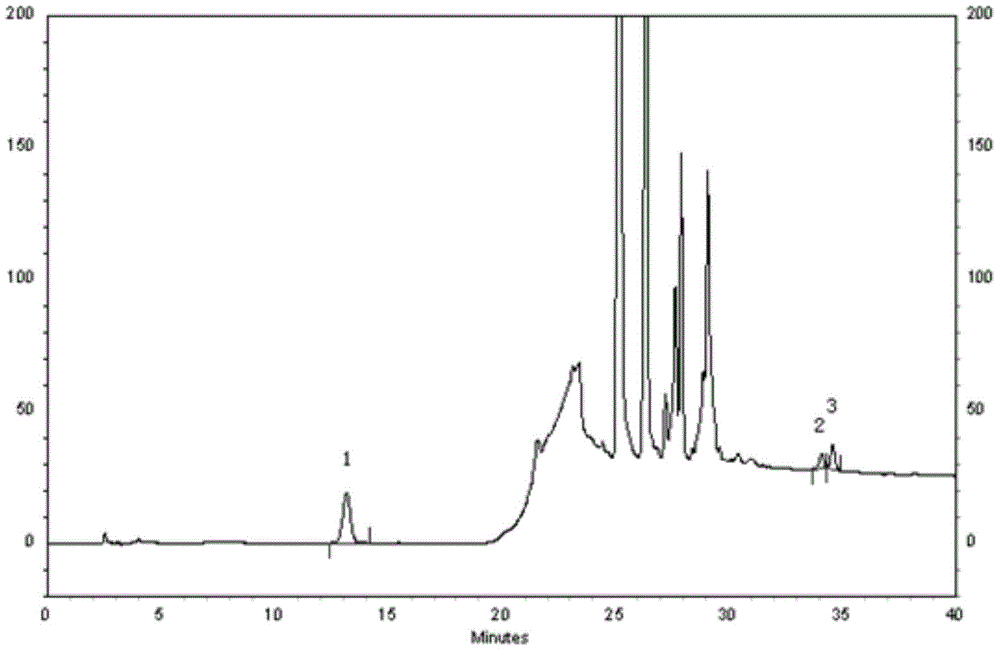

Detection method of pterocephalus hookeri

ActiveCN104237446AComprehensive detectionMeet actual testing needsComponent separationUrsolic acidLoganin

The invention relates to a detection method of pterocephalus hookeri. The detection method is capable of simultaneously detecting loganin, ursolic acid and / or oleanolic acid in pterocephalus hookeri. The separation and content measurement of loganin, ursolic acid and / or oleanolic acid in great polarity difference can be realized by virtue of the simple gradient variation of the flow phase, and the real detection requirement can be further met.

Owner:SHANDONG JINHE DRUG RES DEV

Film forming agent specially used for glass fibers for wind turbine blades, and preparation method thereof

The invention relates to an epoxy resin complex aqueous emulsion. The epoxy resin complex aqueous emulsion is used for preparing a film forming agent used for glass fibers for wind turbine blades. The glass fibers prepared through using the aqueous emulsion as a film forming agent are especially suitable for making wind turbine blades. The aqueous emulsion contains no VOC, contains no nonyl phenol surfactants, and has good safety and environmental protection properties. The wind turbine blades made of the glass fibers drawn through using the aqueous emulsion as the film forming agent have excellent soaking speed, composite material performances and other indexes; and the water emulsion has the advantages of good storage stability and use stability, safe use, and environmental protection. The aqueous emulsion mainly includes epoxy resin, an emulsifier and deionized water. The epoxy resin aqueous emulsion can be used in tank furnace wire drawing working in a large scale manner, the process is stable, and the production cost is low.

Owner:TAISHAN FIBERGLASS INC

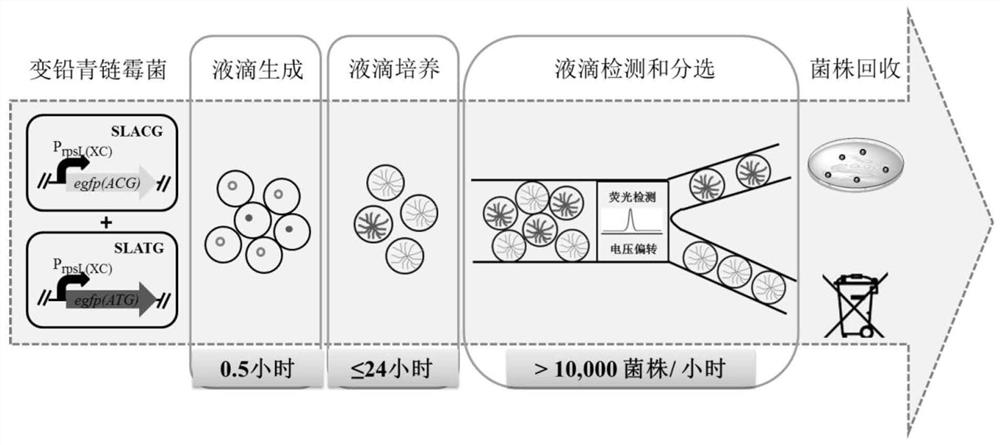

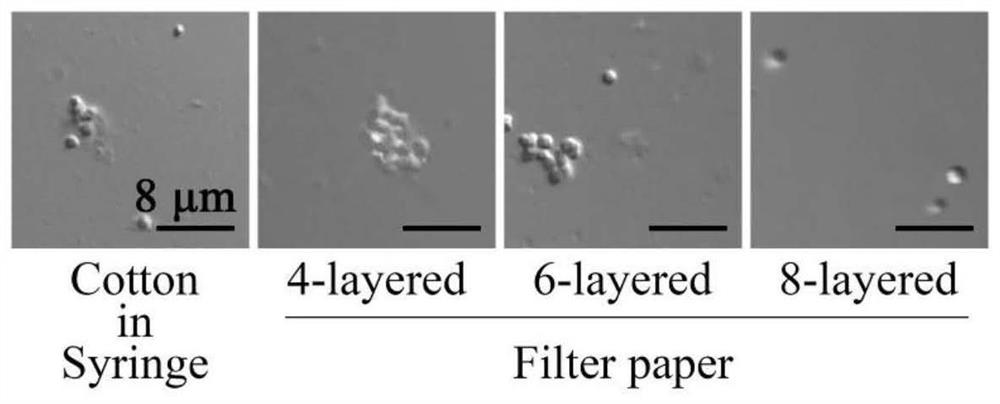

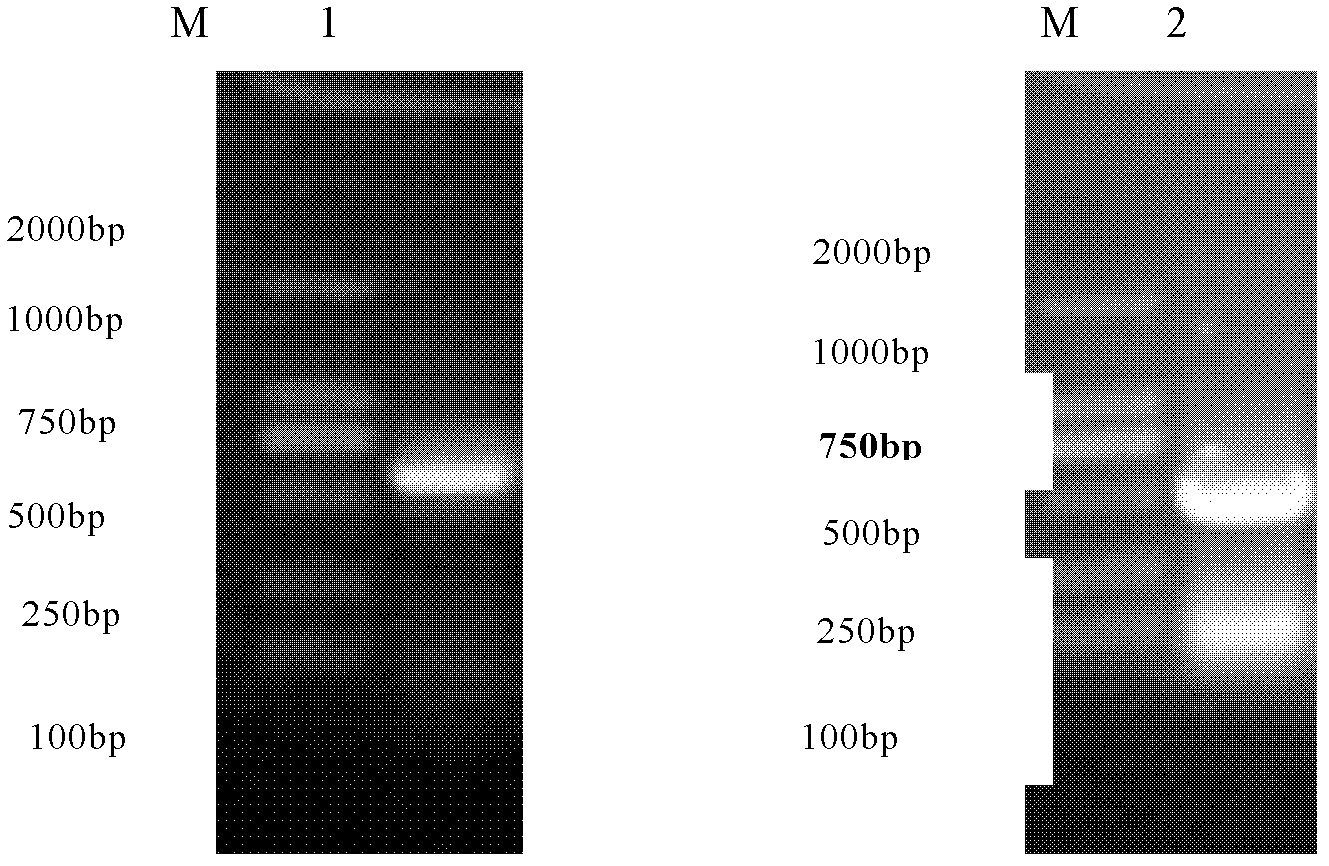

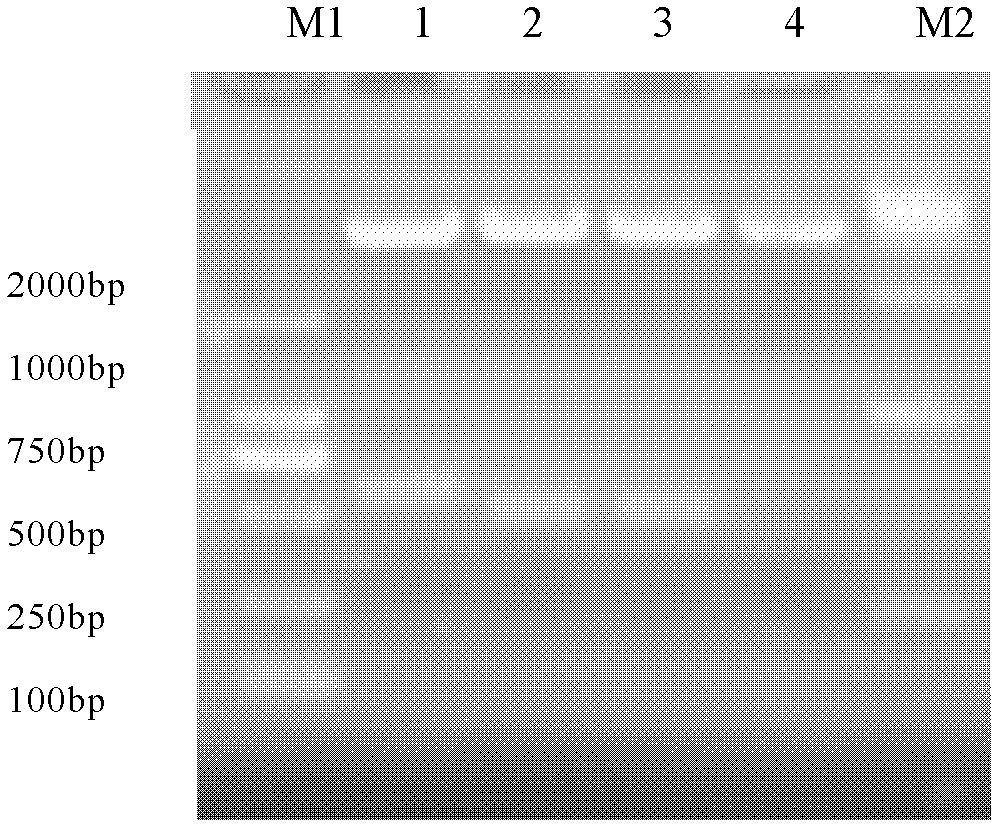

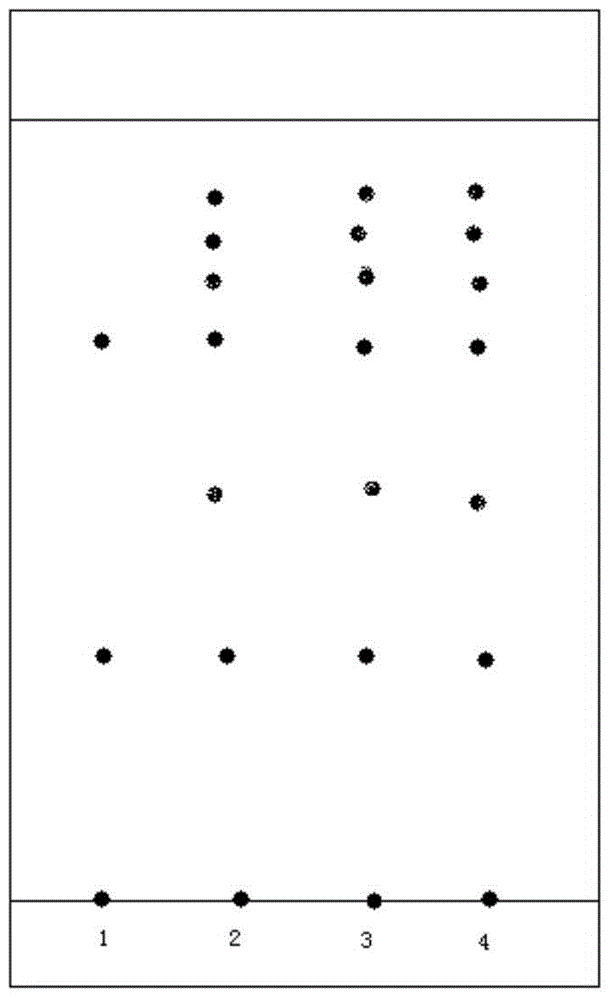

Application of high-throughput screening method using droplet micro-fluidic chip in actinomycetes

PendingCN112852915AWon't punctureBroad detectabilityMicrobiological testing/measurementFluorescence/phosphorescenceSporeHigh-Throughput Screening Methods

The invention discloses an application of a high-throughput screening method using a droplet micro-fluidic chip in actinomycetes, actinomycete monospores can be embedded in a single droplet through the method, the single spores are stably formed in the droplet within the culture time of 0-7 days, the wide detection and sorting time is guaranteed, and in the aspect of detection, by using the method, functional promoters in actinomycetes can be detected at high throughput, or the strength of some unknown promoters can be identified, and promoter elements with proper strength can be screened for subsequent actinomycete strain modification; in the aspect of screening, the screening flux of the method can reach 105 strains per day, a mixed library of positive bacteria generating green fluorescence signals and negative bacteria not generating green fluorescence signals can be successfully sorted, and the enrichment rate of the sorted positive bacteria reaches 81.7% or above and is increased to 26 times compared with 3.1% before sorting.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

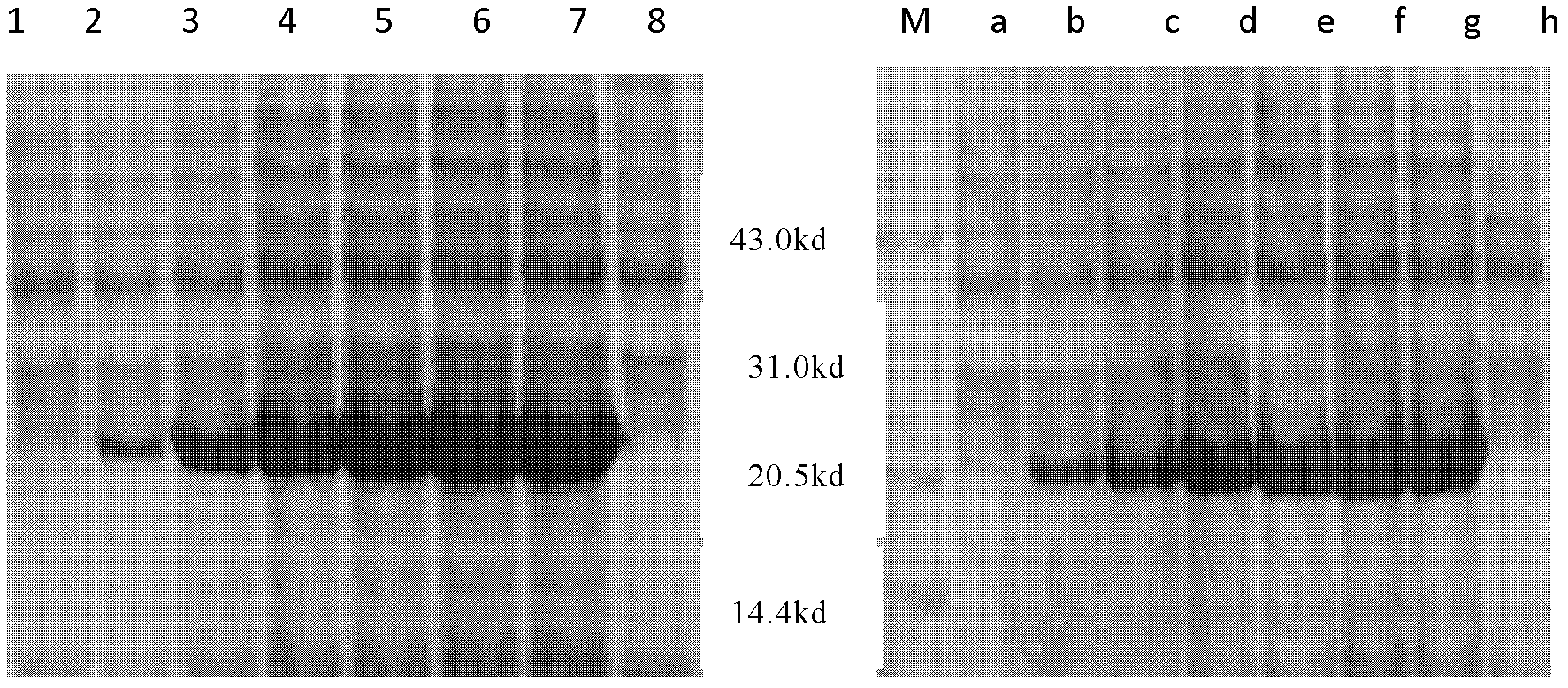

Method for improving prokaryotic expression of antiviral activity of porcine interferon

InactiveCN102329813AInhibition of replication activityGood proportionMicroorganism based processesAntiviralsEscherichia coliDisease

The invention discloses a method for improving the prokaryotic expression of the antiviral activity of a porcine interferon, and the method comprises the following steps: extracting DNA (deoxyribonucleic acid) of porcine white cells and RNA (ribonucleic acid) of porcine spleen, constructing a recombinant expression plasmid, transforming Escherichia coli and inducing the expression of porcine IFN (immunoreactive fibronectin)-alpha and IFN-gamma; and when the weight ratio of the recombinant porcine IFN-alpha to the IFN-gamma is 53:1, and the activity of inhibiting the replication of astrovirus is best. The scheme of the invention provides a production and preparation method of the porcine interferon which is high in expression level and great in purity and a using method for improving the antiviral activity of the interferon, thereby laying a foundation for development of novel gene engineering antiviral preparations, as well as prevention and treatment of porcine infectious diseases.

Owner:SHANGHAI JIAO TONG UNIV +1

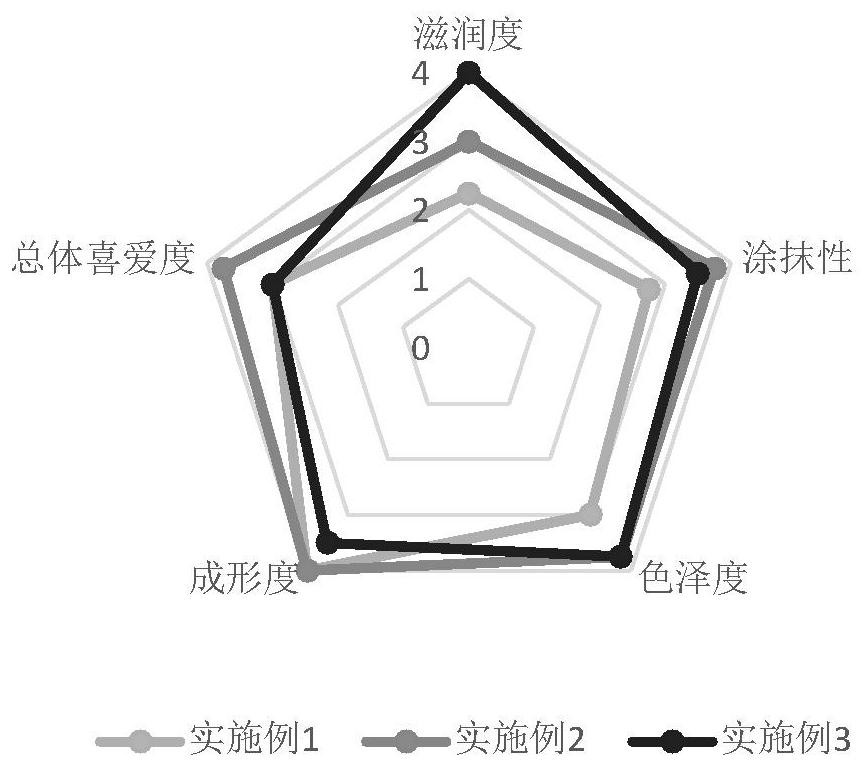

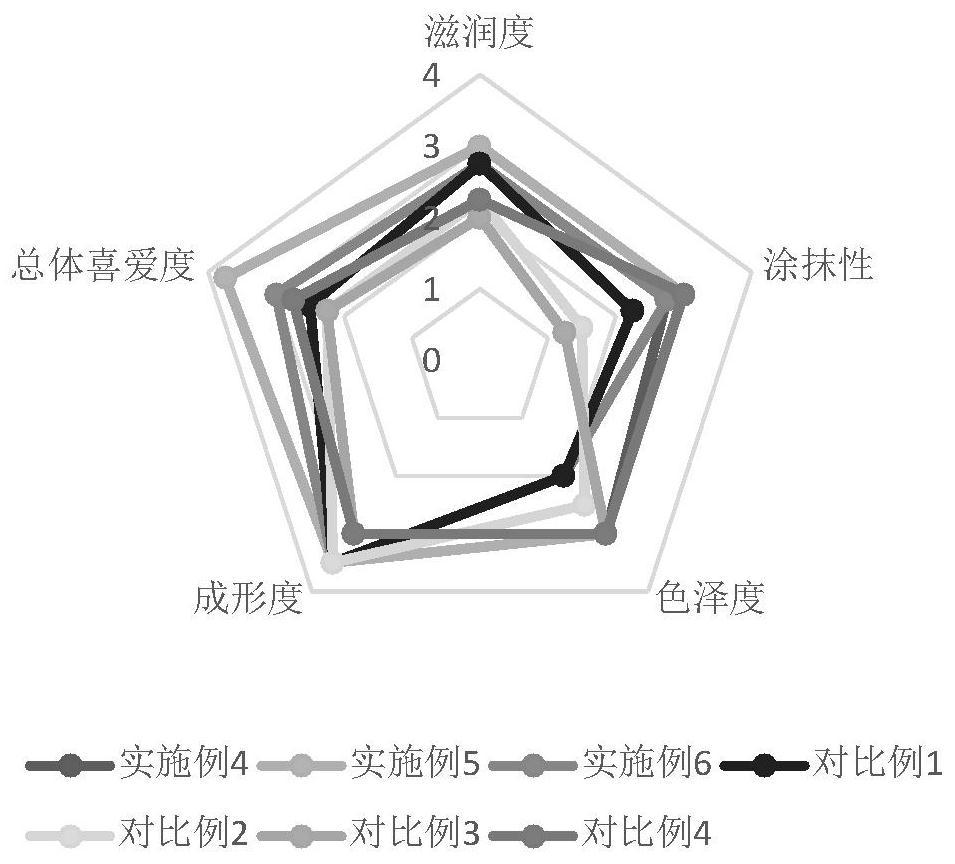

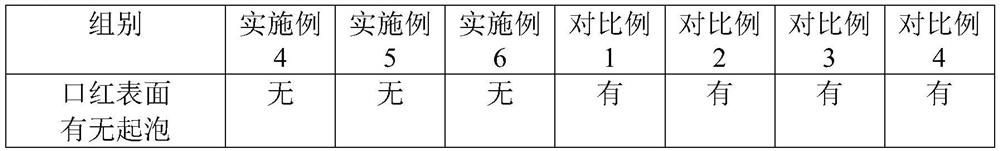

Edible lipstick containing camellia oil and preparation method thereof

The invention discloses an edible lipstick containing camellia oil. The edible lipstick is prepared from the following raw materials of, in parts by mass, 50-70 parts of natural vegetable oil, 14-34 parts of natural wax, 5-10 parts of natural plant pigment, 0-6 parts of vitamin E and 0-6 parts of natural plant essential oil, wherein the natural vegetable oil comprises the camellia oil, and the natural wax comprises beewax and candelilla wax. The invention also discloses a preparation method of the edible lipstick containing the camellia oil. The edible lipstick takes the camellia oil as a maincomponent, and is high in moistening degree, healthy and safe.

Owner:ZHEJIANG UNIV

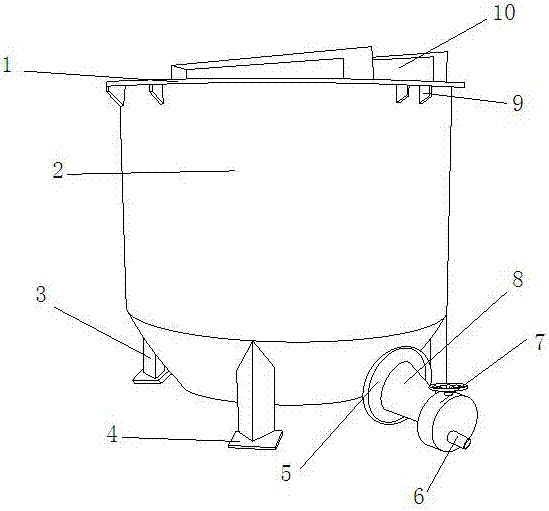

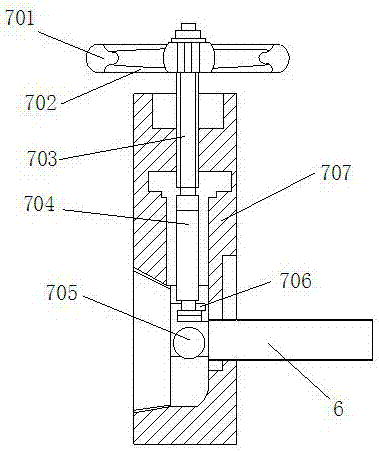

Cement additive storage equipment

The invention discloses cement additive storage equipment. The cement additive storage equipment structurally comprises a box cover, a storage box, support columns, bases, a fixed circular ring, a water outlet pipe, a flow control device, a connecting pipe, support frames and a large handle, wherein the box cover is welded with the bottom of the large handle, the storage box is connected with thefixed circular ring, the support columns and the bases are integrated, the water outlet pipe is embedded with the flow control device, and the connecting pipe is connected with the fixed circular ring. According to the cement additive storage equipment, the flow control device is structurally arranged, cement additives are stored in the storage box, when the cement additive storage equipment needsto be used, a rubber sleeve is matched with the alloy circular ring, a movable shaft is pushed, so that a pressing rod is pushed, a movable valve is controlled according to the state of the pressingrod, a sealing ball and the movable valve are integrated, and finally, the quantity of the cement additives from the connecting pipe to the water outlet pipe is controlled, so that the quantity of theadditives can be accurately controlled, and the cement mixing proportion is preferably prepared.

Owner:江苏润邦再生资源科技股份有限公司

A kind of corn multifunctional soil improvement nutrient controlled release fertilizer and preparation method thereof

InactiveCN105237186BMeet the dosageIncrease productionClimate change adaptationAgriculture gas emission reductionControl releaseSoil properties

The invention relates to a corn multifunctional soil-improving and nutrient-control-released fertilizer, which comprises a biocarbon soil improving material and a chemical fertilizer according to a weight ratio of (13%-17%):(83%-87%). The fertilizer is prepared by combining the biocarbon soil improving material and the chemical fertilizer together according to the weight ratio mentioned above, thus the nutrients in chemical fertilizer can be fully utilized, at the same time, the soil can be improved, and the nutrients can be control-released. Moreover, the fertilizer can prominently increase the content of organic carbon in soil, improve the soil property, and reduce the releasing speed of nutrients, thus the happening rate of farmland pollution is reduced, the nutrient utilization rate is improved, the crop output and the income of farmers are increased, and the effect on corns is the most prominent.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Preparation method of neodymium iron boron magnet

ActiveCN102103916BReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

A method for dyeing cloth

ActiveCN108179573BStrong dipping abilityReduce Dye TimeLiquid/gas/vapor removalLiquid/gas/vapor fabric treatmentPolymer scienceEngineering

The invention relates to the field of cloth processing, and discloses a dyeing method for cloth. The method comprises the steps that dye raw materials are prepared; an unwinding roll, a winding roll,an outer tube, an inner tube, a drying mechanism and a water inlet pipe are prepared; dye B is prepared; gray cloth is coaxially installed on the unwinding roll, and one end of the gray cloth penetrates through a second inlet, a dye cavity, a first inlet, a first outlet and a second outlet in sequence and then fixedly connected to the surface of the winding roll; meanwhile, and the dye B is pouredinto the dye cavity through the water inlet pipe; the winding roll rotates at the rotating speed being 10-20 r / min, at the moment, the gray cloth penetrates through the second inlet and is located atthe dye cavity, the dye B in the dye cavity dyes the gray cloth, and gray cloth A is obtained; the gray cloth A continues to move to pass through the first inlet and the first outlet and is located at the drying mechanism, the drying mechanism dries the gray cloth A, and gray cloth B is obtained, wherein the baking temperature of the drying mechanism on the gray cloth A is 100-200 DEG C; the graycloth B continues to move to pass through the second outlet and then is wound on the winding roll. Accordingly, corrugation generated on the cloth in the dyeing process can be avoided.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

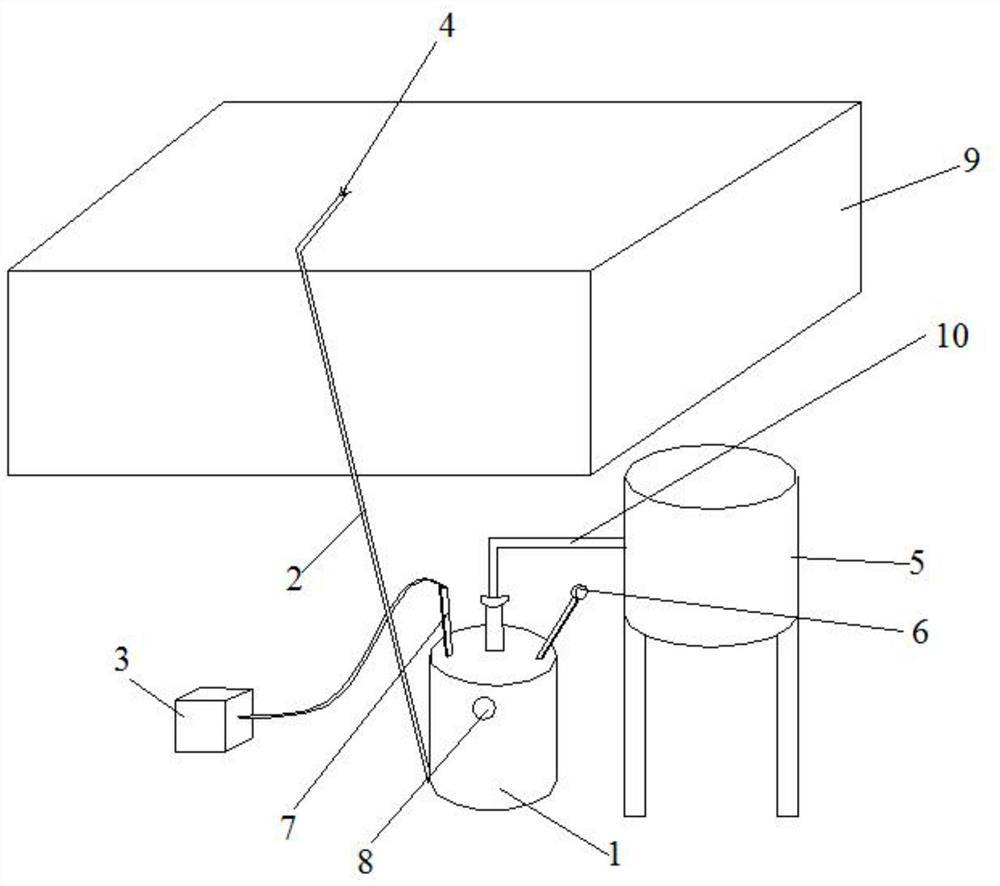

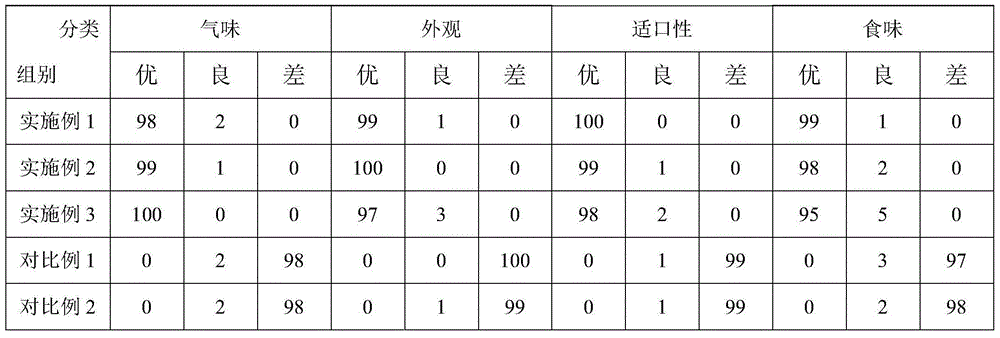

Atomization device and system for preparing composite solid seasonings

The invention discloses an atomization device and system for preparing composite solid seasonings. The system comprises: a storage tank, which is used for temporarily storing liquid ingredients; an air compressor, which communicates with the storage tank through a pipeline and is used for pressurizing the liquid ingredients in the storage tank; a mixing tank, which is used for storing solid raw materials and communicates with the storage tank through a batching pipe, wherein one end, close to the mixing tank, of the batching pipe is a free end, and the free end is positioned above the mixing tank; and at least one atomizing nozzle, which is mounted at the free end of the batching pipe. According to the invention, through the arrangement of the batching pipe, liquid ingredients in the storage tank can flow towards the mixing tank after being rapidly pressed; and through the arrangement of the atomizing nozzle, the liquid ingredients can be atomized and then sprayed to the mixing tank, so the contact area of the liquid ingredients and solid raw materials is greatly increased, and uniform mixing is ensured; and a solid seasoning prepared by mixing the liquid ingredients and the solid raw materials is good in spice taste.

Owner:陕西为康生物科技股份有限公司

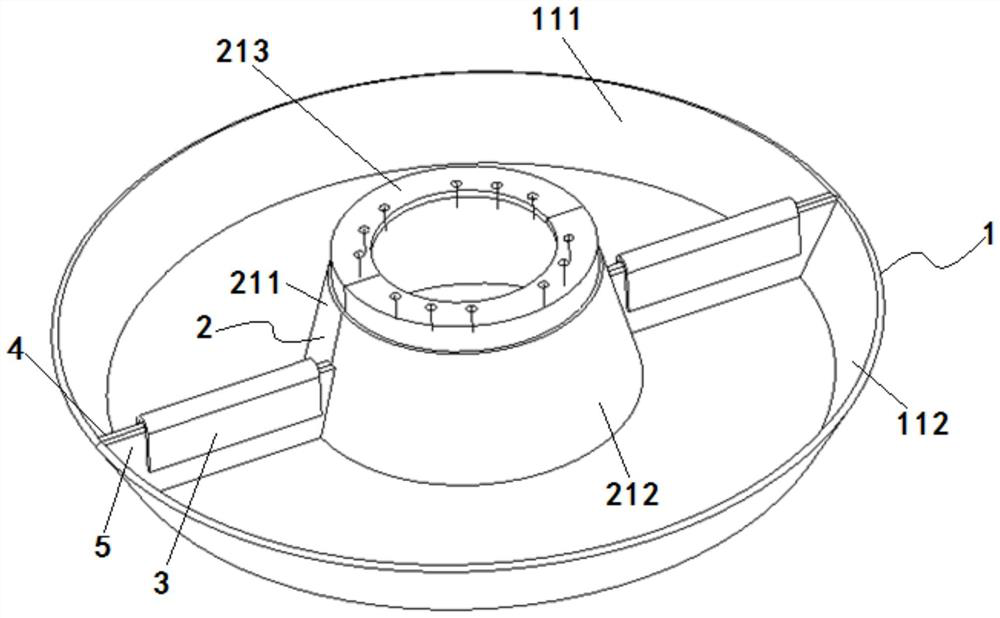

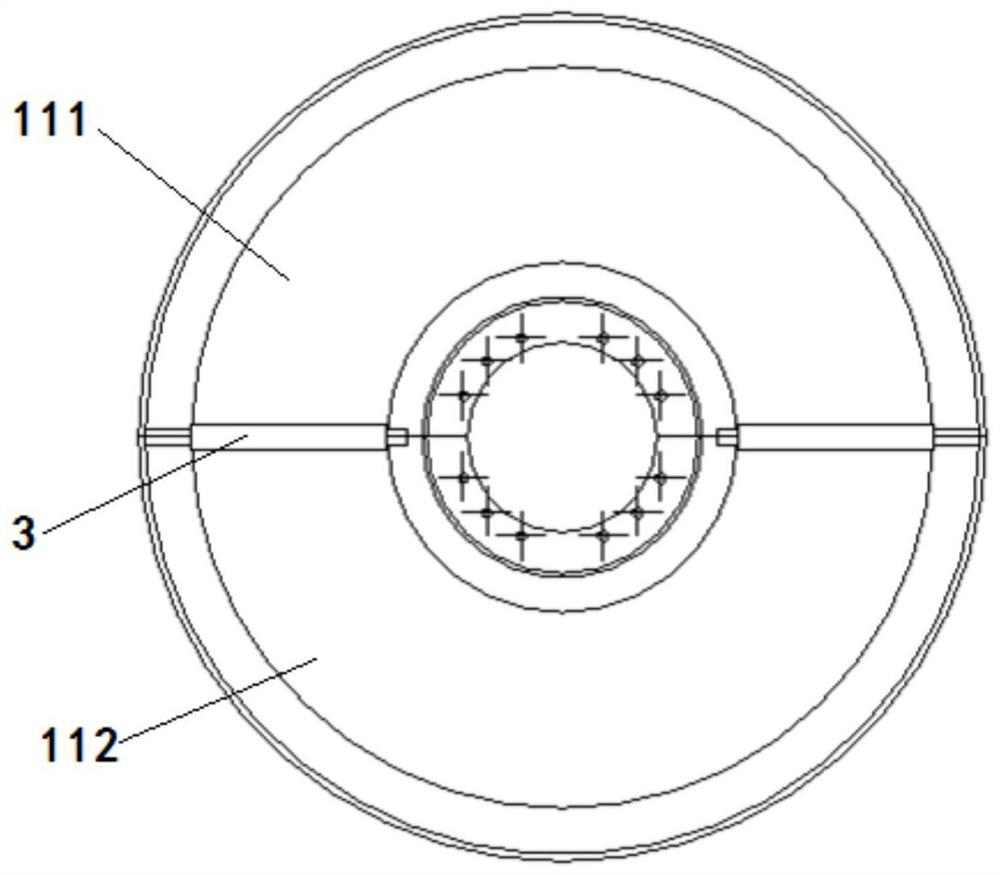

Material receiving disc for directional solidification crystallization furnace and manufacturing method of material receiving disc

ActiveCN113458381AImprove service life and equipment utilizationReduce rework costsFoundry mouldsCasting apparatusInvestment castingDirectional solidification

The invention discloses a material receiving disc for a directional solidification crystallization furnace. The material receiving disc comprises a material receiving disc body with an opening in the top, the surface of the bottom of the material receiving disc body is of an annular structure, a first connecting hole is formed in the inner circle of the material receiving disc body, and a connecting column is coaxially arranged on the first connecting hole; and the connecting column body is integrally connected to the inner wall of the bottom of the material receiving disc body, the connecting column body is of a hollow cavity structure, a second connecting hole is formed in the wall face of the top of the connecting column body, and the second connecting hole and the first connecting hole are coaxially arranged. According to the material receiving disc for the directional solidification crystallization furnace, the repair cost is saved, the design is simple and effective, the cost is low, the material receiving disc is suitable for application and popularization in the investment casting industry, and the problem of unpredictable risk caused by damage caused by molten metal splashing can be solved.

Owner:AECC AVIATION POWER CO LTD

A kind of detection method of pterygium

ActiveCN104237446BComprehensive detectionMeet actual testing needsComponent separationUrsolic acidLoganin

The invention relates to a detection method of pterocephalus hookeri. The detection method is capable of simultaneously detecting loganin, ursolic acid and / or oleanolic acid in pterocephalus hookeri. The separation and content measurement of loganin, ursolic acid and / or oleanolic acid in great polarity difference can be realized by virtue of the simple gradient variation of the flow phase, and the real detection requirement can be further met.

Owner:SHANDONG JINHE DRUG RES DEV

Production technology of 1,2,4-trichlorobenzene

InactiveCN105820032AImprove conversion rateLower the activation energy of the chlorination reactionHalogenated hydrocarbon preparation1,2,4-TrichlorobenzeneBenzene

The invention discloses a production technology of 1,2,4-trichlorobenzene, and belongs to the technical field of fine chemical engineering. The technology comprises the steps of 1 directional chlorination, wherein chlorine is introduced into benzene, and a mixture of p-dichlorobenzene and o-dichlorobenzene is obtained through directional chlorination under the action of a catalyst; 2 catalysis treatment, wherein a lewis acid catalyst is added into the p-dichlorobenzene and o-dichlorobenzene mixture obtained in the step 1 for treatment; 3 rechlorination, wherein chlorine is introduced into mixed liquid obtained through catalysis treatment in the step 2, and chlorination is conducted to obtain a mixture of 1,2,4-trichlorobenzene, p-dichlorobenzene and o-dichlorobenzene; 4 rectification, wherein the mixture obtained in the step 3 is rectified to obtain a 1,2,4-trichlorobenzene product and an unreacted dichlorobenzene mixture, and the dichlorobenzene mixture is taken as a raw material to be repeatedly used in the step 2. The production technology has the advantages of being simple in method, low in cost, high in yield, few in technological by-product and suitable for large-scale industrialized production.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

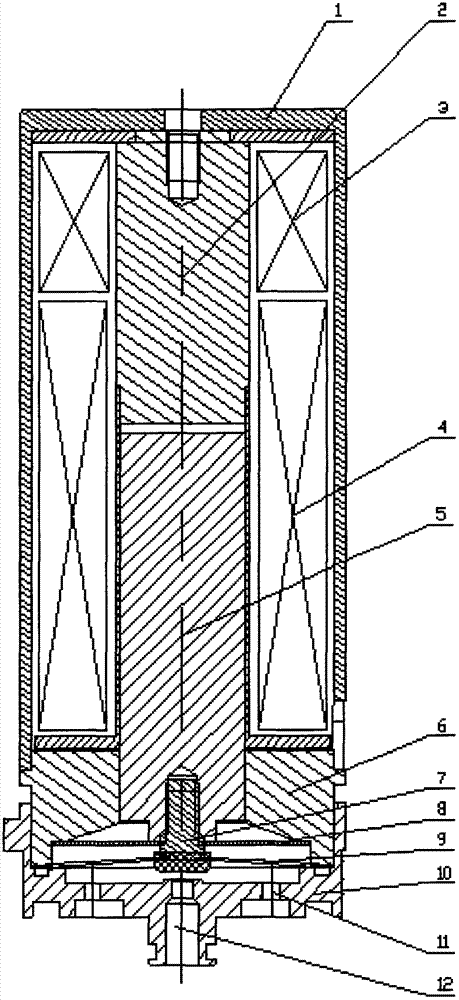

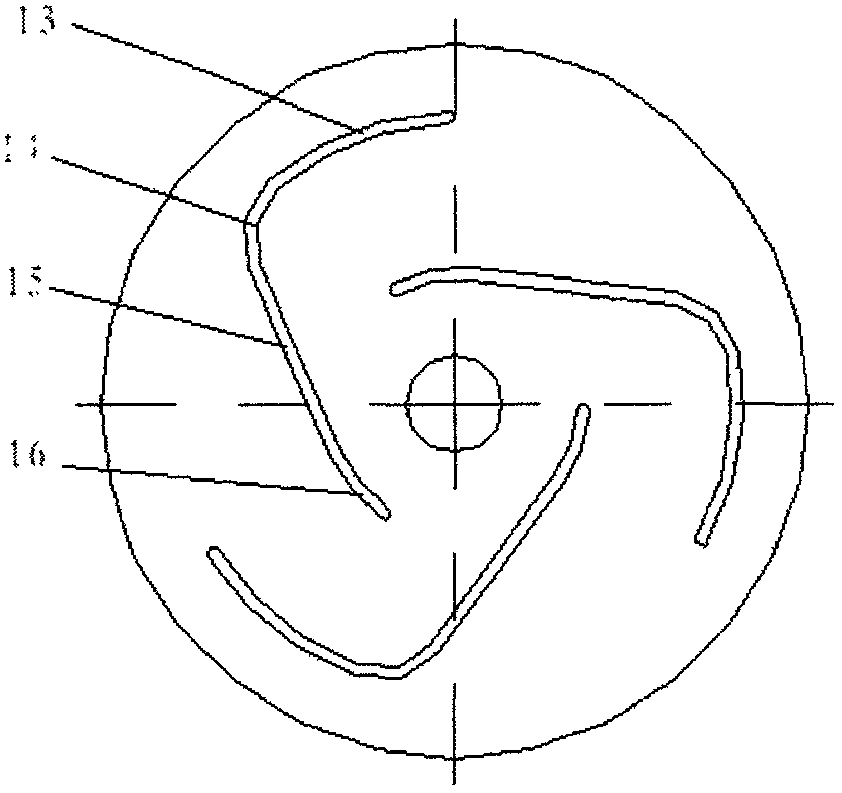

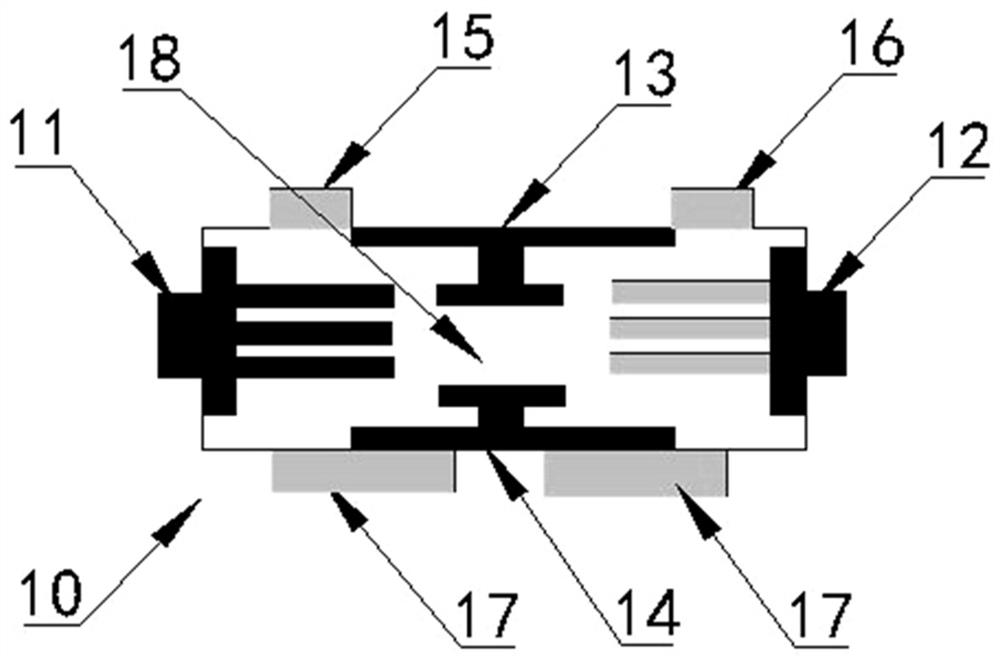

Compensation type micro-control solenoid valve

InactiveCN102661430BHigh control precisionHigh sensitivityOperating means/releasing devices for valvesSolenoid valveEngineering

The invention provides a compensation type micro-control solenoid valve which is composed of a main driving coil, a motion compensation coil, a fixed iron core, a movable iron core, a control circuit and the like. The motion compensation coil and the main driving coil are arranged in parallel; the control circuit controls the motion compensation coil to carry out demagnetization operation; the fixed iron core and the movable iron core are located in the coil; the fixed iron core is fixed with a fixed shell through a locking screw; the movable iron core is located below the fixed iron core; a reed and a membrane are fixed on the movable iron core through a pressing screw; a screw head of the pressing screw is located between the membrane and the reed; a magnetic conduction seat is mounted at the lower end of the shell and the magnetic conduction seat is provided with clamping positions which correspond to the reed and the membrane; the clamping position matched with the membrane is a sealing clamping position. The compensation type micro-control solenoid valve forcedly eliminates the disaster result caused by residual magnetism of a flexible magnetic material of an electromagnetic adjusting valve. The control precision, the flexibility and the stability of the electromagnetic adjusting valve are improved. A stainless steel membrane and a non-linear elastic property reed are adopted, and a resistance vibration-absorption hole is innovatively arranged, so that the influences on controlling the solenoid valve by backpressure fluctuation are greatly reduced.

Owner:黄冈力达实业有限公司

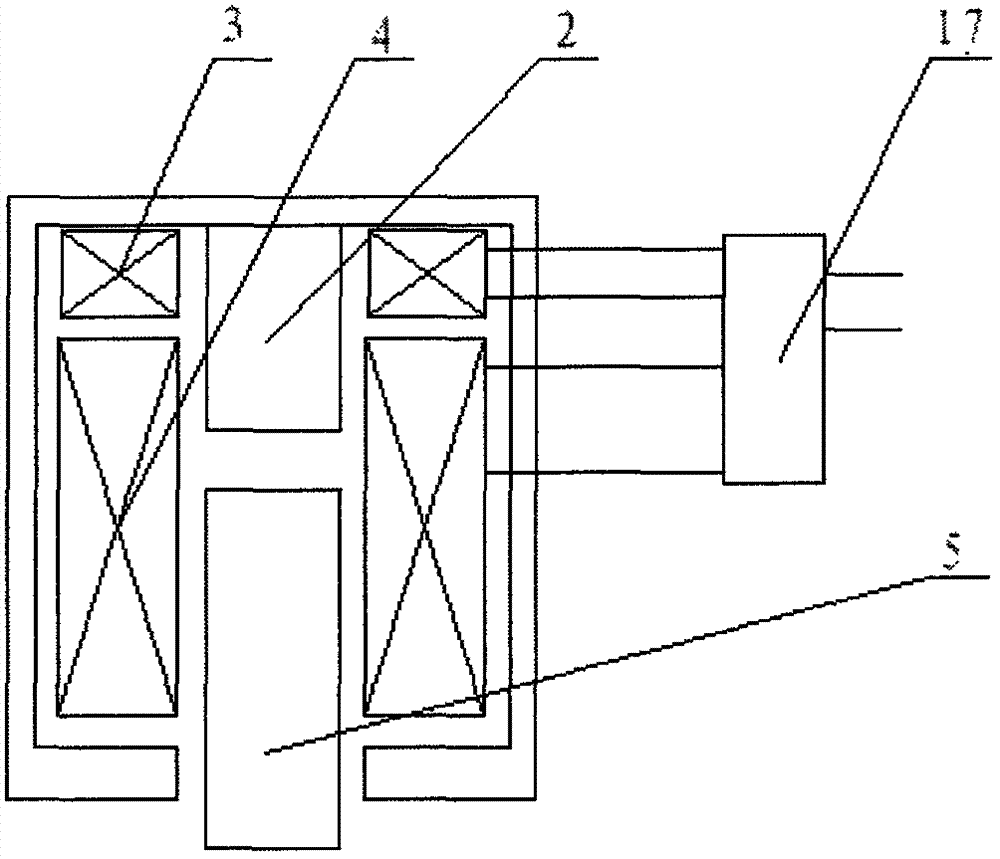

Automobile dual fuel mixing system

InactiveCN103775203AGood proportionReduce pollutionElectrical controlInternal combustion piston enginesGasoline fuelMethanol fuel

Disclosed is an automobile dual fuel mixing system. The automobile dual fuel mixing system comprises a methanol fuel tank and a gasoline fuel tank. The methanol fuel tank is connected with a methanol spray nozzle, the gasoline fuel tank is connected with a gasoline spray nozzle, the methanol spray nozzle and the gasoline spray nozzle are both connected to an engine gas inlet vent and an engine management system, and the engine management system control the on and off of the valves of the spray nozzles. The automobile dual fuel mixing system can control the proportion of methanol and gasoline at the gas inlet vent timely according to the current condition through the engine management system, and accordingly to obtain the optimal proportion among the emission quantities of CO, HC, NOx and formaldehyde to reduce pollution.

Owner:XIAN JIAOTONG UNIV JINGSHENG SCI & TECH DEV

Dust removal apparatus for chocolate candy processing workshop

InactiveCN109954353AImprove work efficiencyProtection against deposits and corrosionCombination devicesWater treatment parameter controlHybrid filterFiber bundle

The invention discloses a dust removal apparatus for a chocolate candy processing workshop. The apparatus comprises a dust treatment box, wherein spraying pipelines are arranged inside the dust treatment box, the right ends of the spraying pipelines are connected with a high pressure pump, the right end of the high pressure pump is connected with a water tank, the water tank is connected with thelower end of the dust treatment box through a pipeline, the pipeline, between the water tank and the dust treatment box, is successively provided with a quartz sand filter, a EPS foam filter bead filter and an efficient fiber bundle and granular activated carbon mixed filter, the upper end of the water tank is provided with a corrosion and scale inhibition agent adding apparatus, the interior of the water tank is provided with a water quality monitoring machine, the right side of the dust treatment box is provided with a control cabinet, a dust detector is arranged on the control cabinet, theupper end of the dust treatment box is provided with a gas outlet pipe, and the upper end of the gas outlet pipe is provided with a purification box. The apparatus has the advantages of simple structure, convenient use, energy saving and environmental protection and good dust removal effects, so that the apparatus can improve the working environment of workers.

Owner:TIANJIN FUXIA FOOD CO LTD

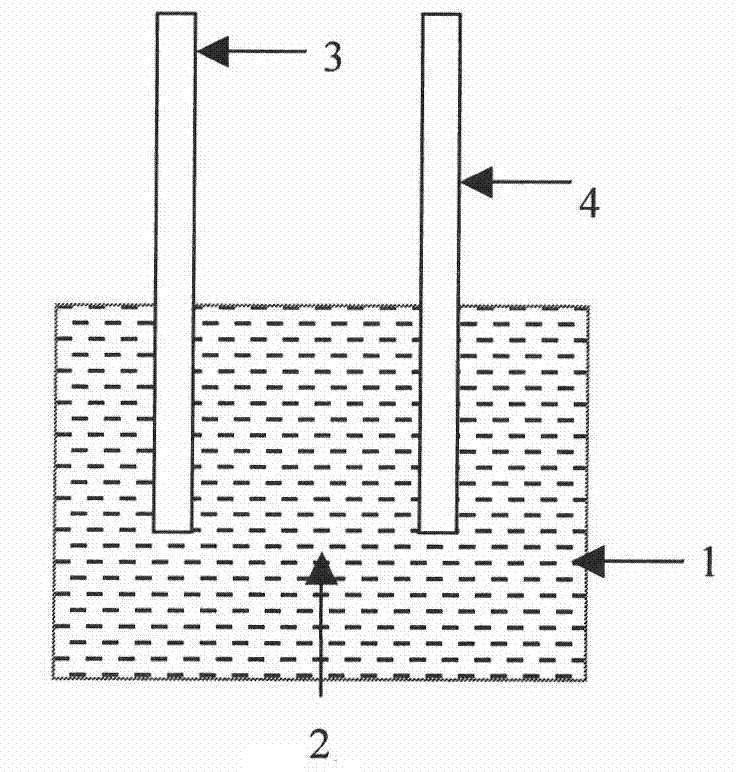

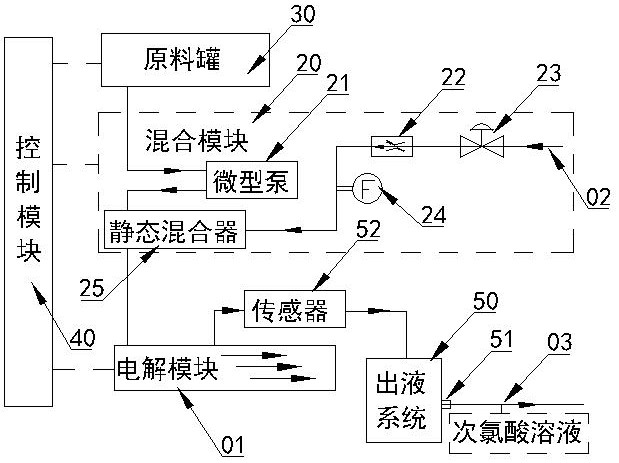

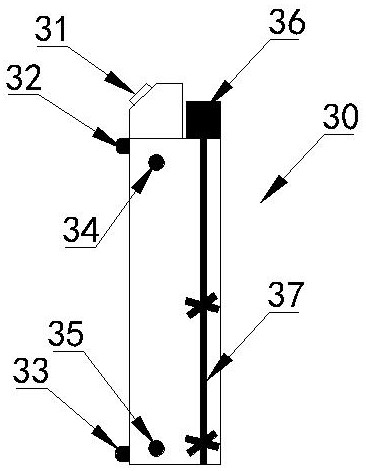

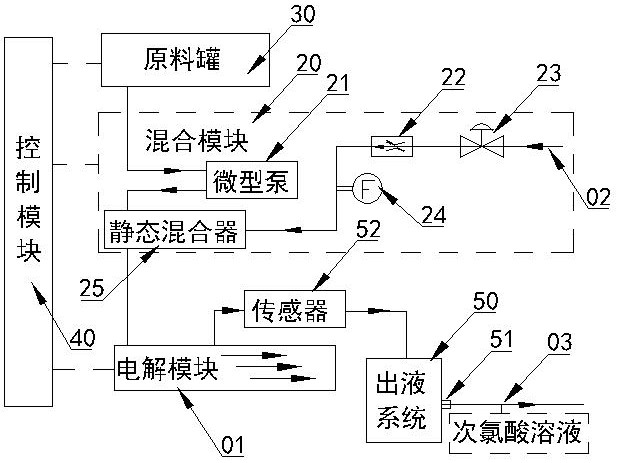

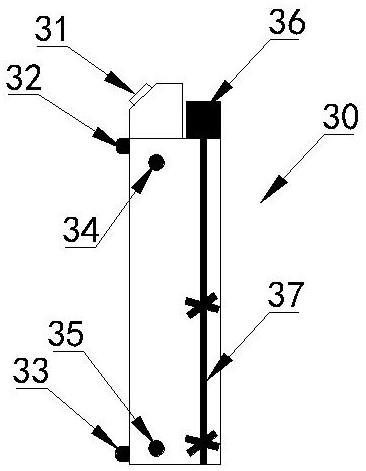

A hypochlorous acid production system and its high-stability hypochlorous acid production method

The invention discloses a hypochlorous acid production system and a high-stability hypochlorous acid production method, comprising a raw material input device, a liquid outlet system, an electrolysis module and an ultrasonic vibrator, the electrolysis module includes an electrolysis cell and an electrolysis power supply, and the ultrasonic vibrator Set in the electrolytic cell of the electrolysis module, the electrolysis module is used to electrolyze the mixed solution of sodium chloride solution and pure water to generate chlorine gas; the ultrasonic vibrator is used to use ultrasonic vibration to make the chlorine gas generated by the electrolysis module form nano-scale cavitation bubbles; At the moment when the cavitation bubbles are broken, the ultrasonic vibration is used to synthesize and break the bubbles again. The cavitation bubbles generate local temperature and pressure diffusion at the moment of formation and collapse, and complete the synthesis of a highly stable hypochlorous acid solution. It can produce hypochlorous acid solution with high stability, improve the chemical performance stability of hypochlorous acid, improve the possibility of longer-term storage, and increase the application degree of hypochlorous acid.

Owner:NINGBO BAYI IND

Power station boiler efficiency calculation method, blended coal combustion proportion optimization method and operation oxygen amount optimization method

PendingCN114638109ASolve the technical limitations of only doing industrial analysisReduce mistakesDesign optimisation/simulationSpecial data processing applicationsPower stationElement analysis

The invention discloses a power station boiler efficiency calculation method, a mixed coal combustion proportion optimization method and an operation oxygen amount optimization method. The boiler efficiency calculation method comprises the following steps: collecting industrial parameter indexes of a sample; calculating unknown parameters of the sample; calculating a judgment factor of the sample coal type; searching two upper limit judgment factors and two lower limit judgment factors which are closest to the judgment factors of the sample coal types; the flue gas is corrected, and the change rate of the corrected boiler efficiency is calculated; calculating the change rate of the boiler efficiency after the exhaust gas temperature is corrected; calculating the boiler efficiency after the exhaust gas temperature is corrected; obtaining a target filtering efficiency calculation result; setting a boundary condition 1; setting a boundary condition 2; and calculating a final calculation result of the target boiler efficiency. According to the power station boiler efficiency calculation method, a big data analysis model can be established, a bridge between coal quality industrial analysis and element analysis can be established, and barrier-free butt joint of industrial analysis and boiler efficiency calculation is achieved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

An easy-to-operate noodle machine, detection method and processing method of the noodle machine

ActiveCN104206466BAffect normal useEasy to operateMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringMechanical engineering

The invention discloses a noodle maker convenient for operation. The noodle maker comprises a base, a stirring cup connected to the base and an upper cover covering the stirring cup. The noodle maker is provided with a stirring assembly and a dough extrusion assembly. The noodle maker is characterized in that the noodle maker comprises a weighing unit and a control unit for controlling the weighing unit, the noodle maker is provided with a protection structure, the protection structure is arranged at the weighing unit, and a safe stroke of the protection structure is less than a safe stroke of the weighing unit. The existing noodle maker is provided with the weighing unit so that a user can accurately control use amounts of flour and a liquid and the noodle maker normal-use is not influenced by inappropriate operation through a user. The noodle maker provided by the invention is provided with the control unit so that corresponding liquid weight can be automatically calculated after flour addition and the noodle maker gives a liquid weight prompt for the user and thus use operation is simplified.

Owner:JOYOUNG CO LTD

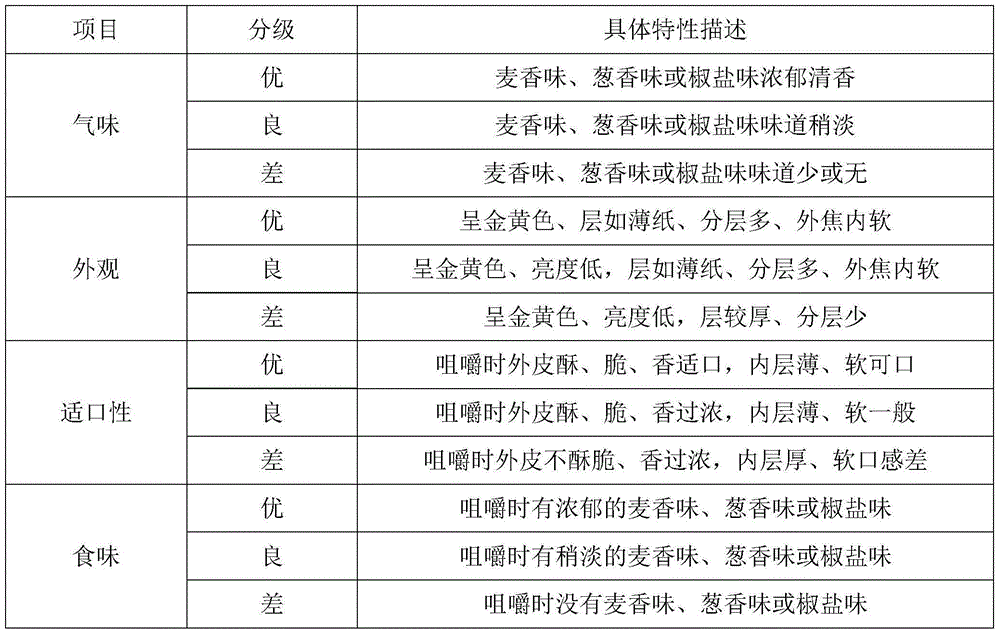

Quick-freezing fresh-keeping shredded cake and making method thereof

ActiveCN103734218BImprove fluffinessEasy to eatDough treatmentBakery productsQuick FreezeCooking & baking

The invention discloses a piece of quick-freezing fresh-keeping shredded cake and a making method thereof. The quick-freezing fresh-keeping shredded cake comprises, by weight, 245 parts to 255 parts of plain flour, 20 parts to 30 parts of cassava modified starch, 4 parts to 6 parts of salt, 1 part to 1.4 parts of chicken powder, 35 parts to 45 parts of lard oil, 3 parts to 5 parts of white sugar, 1.5 parts to 2.5 parts of Vitamin E, 9 parts to 11 parts of soybean oil, 3 parts to 5 parts of sesame, 5 parts to 7 parts of chive, 0.1 part to 0.3 part of fresh ginger, 0.2 part to 0.3 part of white radish, 0.4 part to 0.6 part of onion, 0.2 part to 0.3 part of Chinese prickly ash, 0.3 part to 0.4 part of sodium hexametaphosphate and 125 parts to 135 parts of water. The quick-freezing fresh-keeping shredded cake is easy and convenient to eat, can be baked on site by an electric baking pan or an oven, the freshly-baked shredded cake is overlapped in layers, the inner layer is thin as paper, the outer layer is brown and crisp, the taste is tough and chewy, and the quick-freezing fresh-keeping shredded cake also has wheat flavor or onion flavor or spiced salt flavor.

Owner:云鹤食品有限公司

Low-acidity acetate material esterification reaction system

InactiveCN111170858APrevent acid flushingReduce loadCarboxylic acid esters separation/purificationFluid phasePhysical chemistry

The invention relates to a low-acidity acetate material esterification reaction system, which comprises an esterification tower, wherein a material inlet and a water inlet are formed in the bottom ofthe esterification tower, a crude product outlet is formed in the top of the esterification tower, and is connected with a rectifying tower, a filler is mounted in the middle of the esterification tower, the filler section of the esterification tower is provided with a middle discharge port and an esterification tower gas phase inlet, the discharge port is located at 50-70% of the filler height, the esterification tower gas phase inlet is located at 40-60% of the filler height, the discharge port is located above the esterification tower gas phase inlet, a phase splitter is arranged inside oroutside the esterification tower, the inlet of the phase splitter is connected with the middle discharge port, the gas phase outlet of the phase splitter is connected with the gas phase inlet of the esterification tower, the liquid phase outlet of the phase splitter is divided into two branches respectively connected with the water inlets of a recovery tower and the esterification tower, and the water inlet of the esterification tower is connected with a water supplementing branch.

Owner:史红桂

Hypochlorous acid production system and high-stability hypochlorous acid production method thereof

The invention discloses a hypochlorous acid production system and a high-stability hypochlorous acid production method thereof. The hypochlorous acid production system comprises a raw material input device, a liquid outlet system, an electrolysis module and an ultrasonic vibrator. The electrolysis module comprises an electrolytic bath and an electrolysis power supply, and the ultrasonic vibrator is arranged in the electrolytic bath of the electrolysis module; the electrolysis module is used for electrolyzing the mixed solution of the sodium chloride solution and the pure water and generating chlorine; the ultrasonic vibrator is used for enabling chlorine generated by the electrolysis module to form nanoscale cavitation bubbles by utilizing ultrasonic vibration; at the moment when the cavitation bubbles are broken, the bubbles are synthesized and broken again through ultrasonic vibration, local temperature and pressure diffusion is generated at the moment when the cavitation bubbles areformed and broken, and synthesis of the hypochlorous acid solution with high stability is completed. The hypochlorous acid solution with high stability can be produced, the chemical property stability of hypochlorous acid is improved, the longer-term storage possibility is improved, and the hypochlorous acid application degree is improved.

Owner:NINGBO BAYI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com