Compensation type micro-control solenoid valve

A solenoid valve and compensation technology, applied in the field of electrical components, can solve the problems of unsolvable control process and unbalanced response of solenoid valve, and achieve the effects of improving control accuracy, resolution and variable range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be described in detail below in conjunction with the drawings and specific embodiments, but the drawings and specific embodiments are not intended to limit the technical solutions claimed in the present invention.

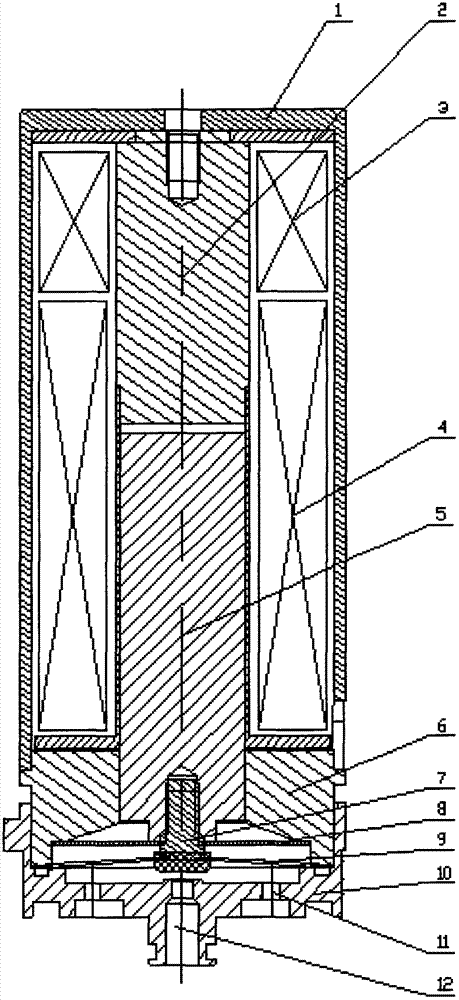

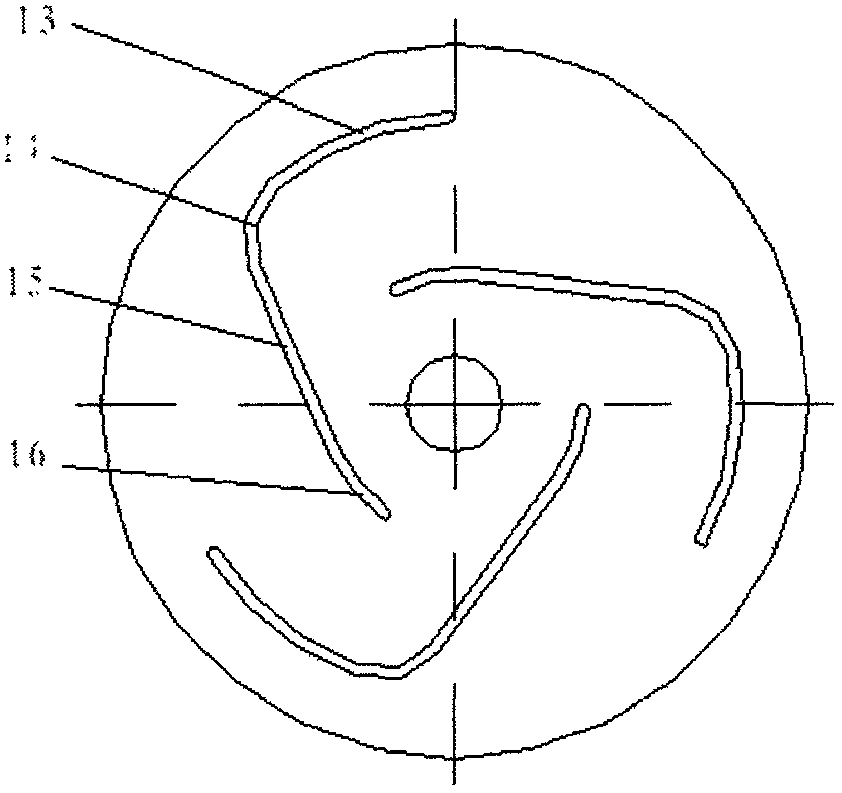

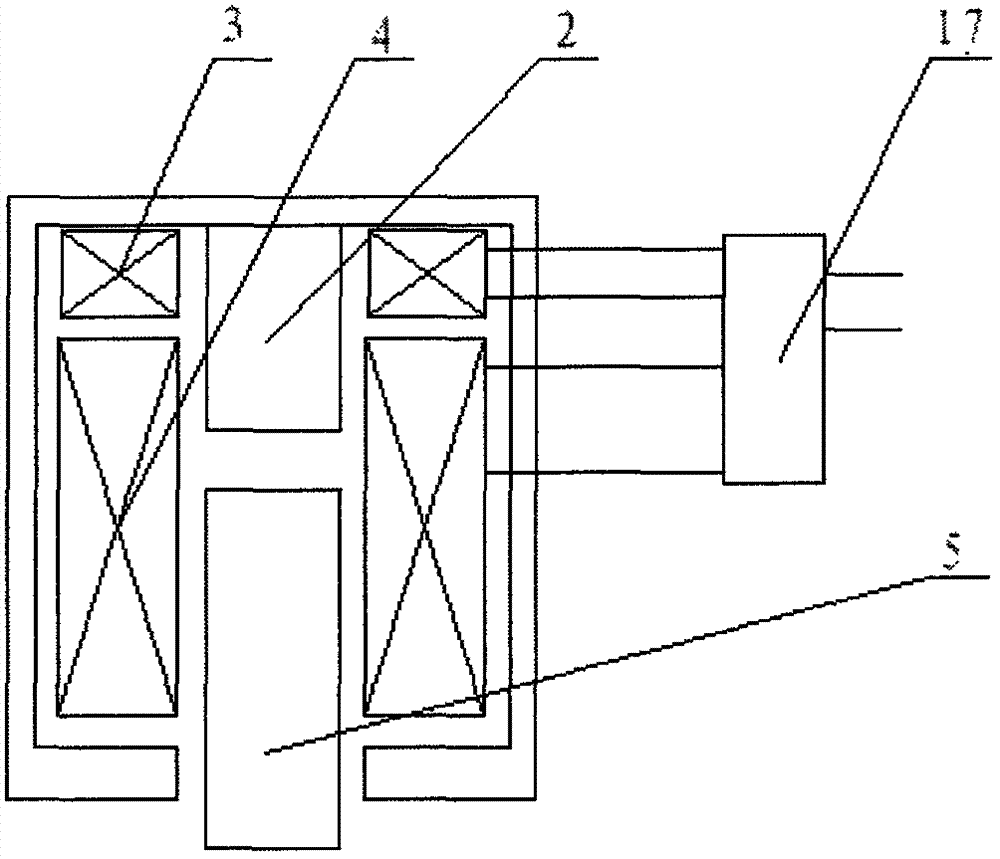

[0012] The present invention is implemented through the following embodiments: the fixed iron core 2 and the moving iron core 5 are located in the coil, the fixed iron core 2 is fixed to the solenoid valve housing 1 by locking screws, the moving iron core 5 is located below the fixed iron core 2, and the reed 8 The diaphragm 9 is fixed on the moving iron core 5 through the compression screw 7, the screw head of the compression screw is located between the diaphragm 9 and the reed 8, the magnetic permeable base 6 is installed at the lower end of the shell, and the magnetic permeable base 6 has a The corresponding clamping position of the reed 8 and the diaphragm 9, the clamping position matched with the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com