Capsule type compound pesticide formulation and preparation method and application thereof

A technology of pesticides and microcapsules, applied in the field of pesticides, can solve the problems of decreased suspension rate of wettable powders, poor dispersion of preparations, and reduced drug efficacy, and achieve the effects of easy industrial production, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

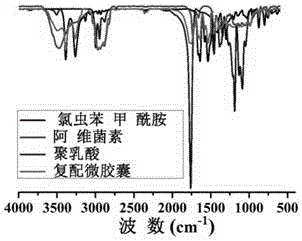

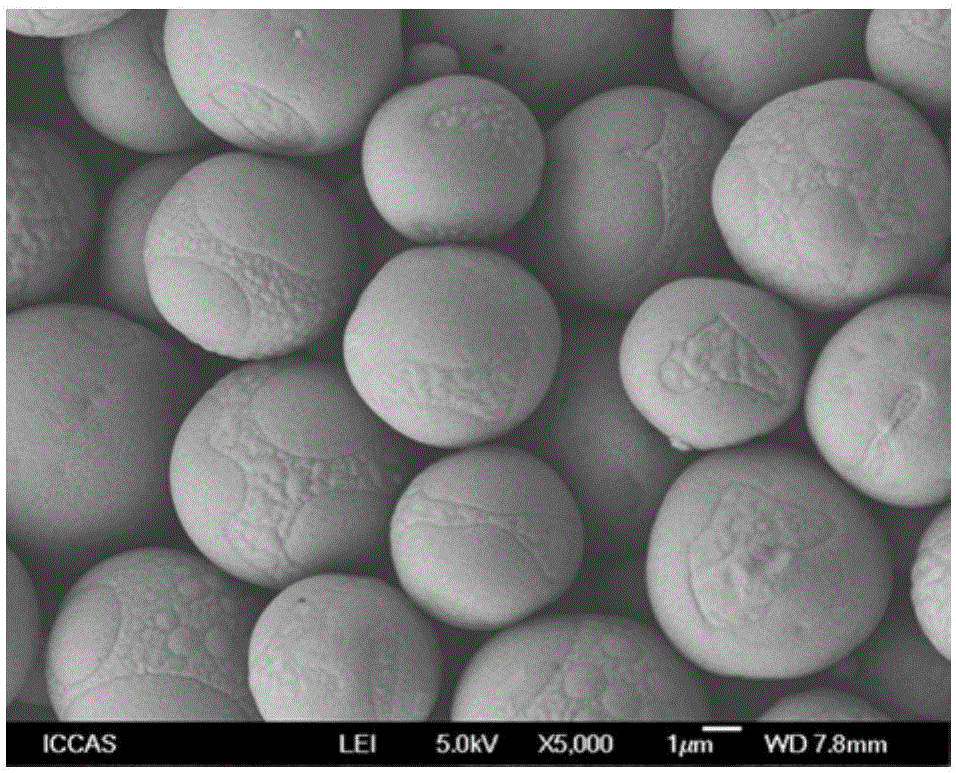

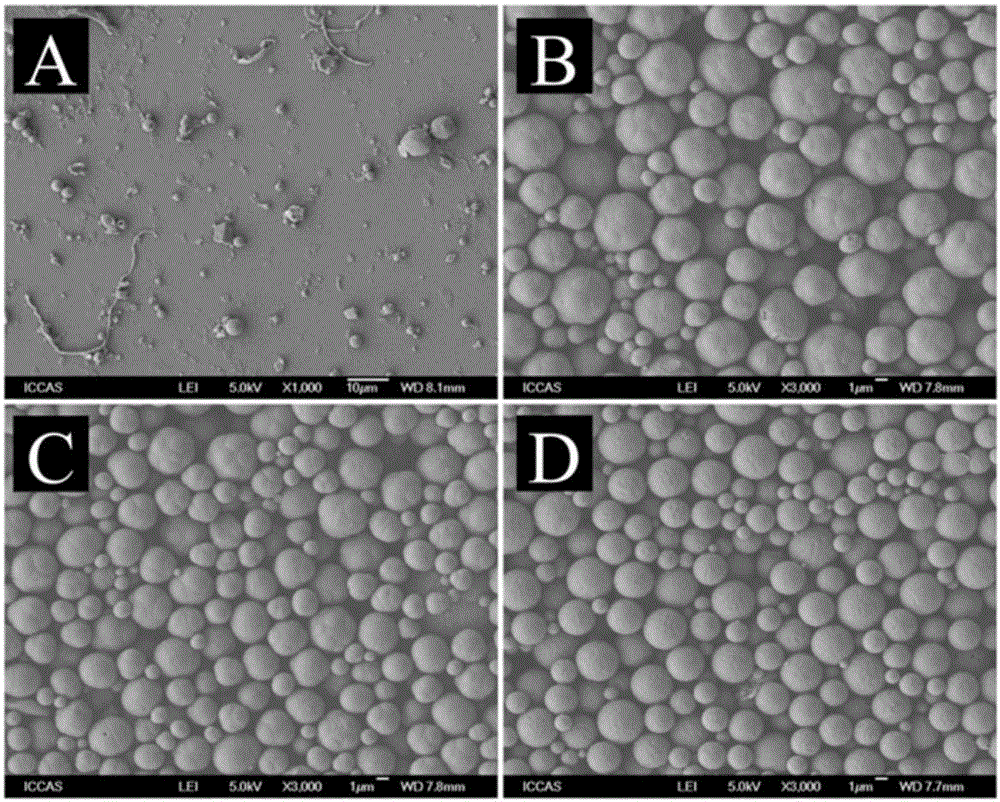

[0059] Embodiment 1, preparation Abamectin · chlorantraniliprole composite microcapsules

[0060] 1) Ultrasonic dispersion of the pesticide A chlorantraniliprole in secondary water to obtain a 5% suspension by weight of the drug as the internal water phase.

[0061] Dissolve the pesticide B avermectin and the synthetic degradable polymer material industrial polylactic acid with a molecular weight of 5,000 to 500,000 in dichloromethane, and prepare the concentration of abamectin and industrial polylactic acid to be 100mg / mL and 100mg / mL respectively mixed solution as the oil phase.

[0062] After the oil phase and the inner water phase were mixed according to the volume ratio of 5:1, the water-in-oil primary emulsion was obtained by ultrasonicating for 2 minutes under the ultrasonic power of 400W.

[0063] 2) Dissolving polyvinyl alcohol in water to prepare a 1.0% polyvinyl alcohol aqueous solution as the external water phase.

[0064] The water-in-oil primary emulsion obtain...

Embodiment 2

[0068] Embodiment 2, preparation Abamectin · chlorantraniliprole composite microcapsules

[0069] 1) Ultrasonic dispersion of the pesticide A chlorantraniliprole in secondary water to obtain a 10% drug by weight suspension as the internal water phase.

[0070] Dissolve the pesticide B abamectin and the synthetic degradable polymer material industrial polylactic acid with a molecular weight of 5,000 to 500,000 in dichloromethane, and prepare the concentration of abamectin and industrial polylactic acid to be 50mg / mL and 100mg / mL respectively mixed solution as the oil phase.

[0071] The oil phase obtained in the step (2) is mixed with the internal water phase obtained in the step (1) according to a volume ratio of 2:1, and then ultrasonicated for 1 min at an ultrasonic power of 200 W to obtain a water-in-oil primary emulsion.

[0072] 2) Dissolving polyvinyl alcohol in water to prepare a 1.0% polyvinyl alcohol aqueous solution as the external water phase.

[0073] The water-i...

Embodiment 3

[0077] Example 3, Preparation of Abamectin Chlorantraniliprole Composite Microcapsules

[0078] 1) Ultrasonic dispersion of the pesticide A chlorantraniliprole in secondary water to obtain a 10% drug by weight suspension as the internal water phase.

[0079] Dissolve the pesticide B avermectin and the synthetic degradable polymer material industrial polylactic acid with a molecular weight of 5,000 to 500,000 in dichloromethane, and prepare the concentration of abamectin and industrial polylactic acid to be 40mg / mL and 100mg / mL respectively mixed solution as the oil phase.

[0080] The oil phase obtained in the step (2) is mixed with the internal water phase obtained in the step (1) according to a volume ratio of 2:1, and then ultrasonicated for 1 min at an ultrasonic power of 200 W to prepare a water-in-oil primary emulsion.

[0081] 2) Dissolving polyvinyl alcohol in water to prepare a 1.0% polyvinyl alcohol aqueous solution as the external water phase.

[0082] The water-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com