Noodle maker convenient for operation, detection method of noodle maker and processing method of noodle maker

An easy-to-operate, noodle machine technology, applied in the directions of dough extruders, measuring devices, and horizontal installation tools for mixing/kneading, etc., which can solve the problem that the noodle processing cannot be effectively completed, the user's enthusiasm for use is reduced, and the satisfaction of the product is affected. To prevent the quality of noodles from declining, the force is uniform, and the operation is simplified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0096] As the noodle machine that is easy to operate according to the present invention, such as Figure 13 As shown, the difference from Embodiment 1 is that the noodle machine is also provided with a water tank and an automatic water inlet structure.

[0097] Such as Figure 13 As shown, the noodle machine further includes a water tank 9, a water pump 92 and a pipeline 91, the pipeline 91 communicates with the stirring cup 21, and the water pump 92 can transport the water in the water tank 9 through the pipeline 91 into the mixing cup 21.

[0098] The advantage of such setting is: the water tank and the automatic water inlet structure are set, and water can be automatically fed into the noodle machine when the noodle machine is working, without the need for the user to add water, which is convenient to use and at the same time, the control is more precise.

[0099] As the method for detecting the amount of noodle feeding in Example 2, the method includes: the user adds water...

Embodiment 3

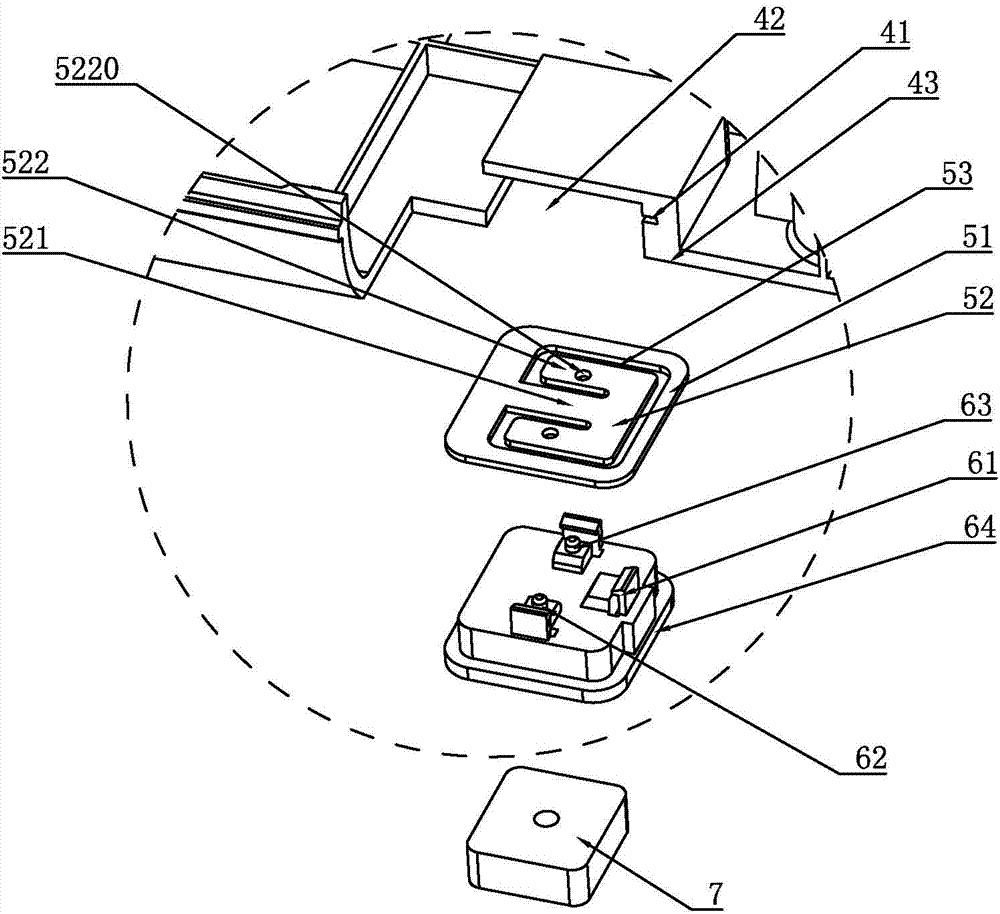

[0102] As the noodle machine that is easy to operate according to the present invention, such as Figure 14 As shown, the difference from Embodiment 1 is that the noodle machine is also provided with an adjustable foot pad.

[0103] Such as Figure 14 As shown, the support foot 6 is threadedly connected to the foot pad 7 , and the foot pad 7 can be rotated to adjust the matching height with the support foot 6 .

[0104] The advantage of such setting is that when the noodle machine is placed, it cannot be guaranteed that the four supporting legs are evenly stressed, which will lead to inaccurate weighing. Adjustable foot pads are set to adjust the cooperation between the supporting feet and the table top, so that the force on the four supporting feet is even, ensuring the accuracy of weighing.

[0105] It can be understood that the number of adjustable foot pads can be set to 1, 2, 3, or 4.

[0106] It can be understood that the adjustment foot pad is in sliding fit with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com