A kind of corn multifunctional soil improvement nutrient controlled release fertilizer and preparation method thereof

A soil improvement and controlled-release fertilizer technology, which is applied to fertilizer mixtures, fertilization devices, and agricultural gas emission reduction, can solve problems such as unreasonable nutrient composition, slowed soil water infiltration rate, and unreasonable nutrient distribution ratio. Achieve the effects of increasing grain production and farmers' income, slowing down the rate of nutrient release, and improving nutrient utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

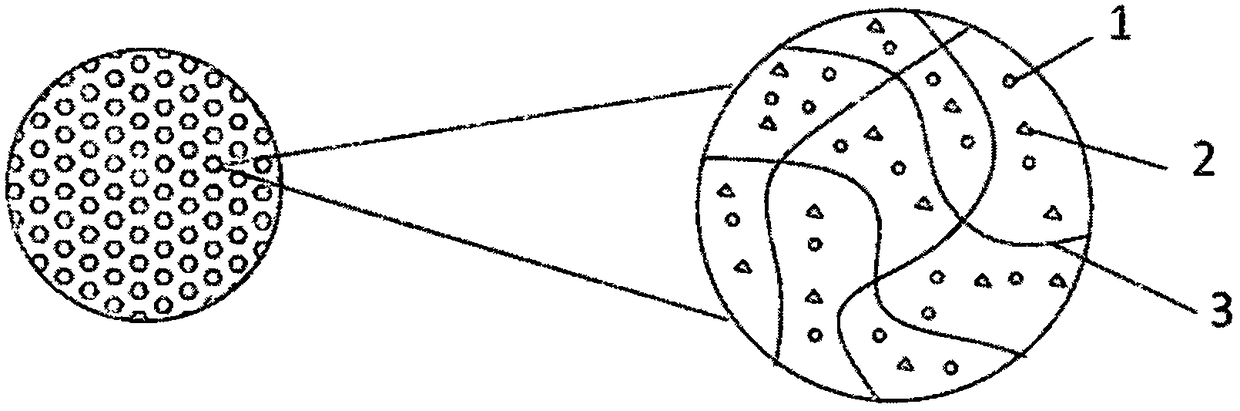

Image

Examples

Embodiment 1

[0039] 1. Prepare materials according to the following types and amounts:

[0040] Weigh 31.6kg of urea, 30.4kg of diammonium phosphate, 20kg of potassium sulfate, 1kg of zinc sulfate, 0.12kg of thiophosphoric acid triamide, 0.08kg of dicyandiamide, 10kg of biomass charcoal, 6.5kg of attapulgite, polyacrylamide polymer Polymer 0.3kg.

[0041] 2. The urea, diammonium phosphate, potassium sulfate, zinc sulfate, triamide thiophosphate, dicyandiamide, biomass charcoal, and attapulgite weighed in step 1 are uniformly mixed according to the above ratio to obtain a mixture;

[0042] 3. The mixture obtained in step 2 is sent to a disc granulator, and the aqueous solution of polyacrylamide polymer is sprayed at a rate of 1 liter / min for granulation. In the aqueous solution of polyacrylamide polymer, polypropylene The mass ratio of amide polymer to water is 1:300. The obtained granular fertilizer is dried at 70°C for 30 minutes, cooled with natural ventilation for 1 hour to room temperature, ...

Embodiment 2

[0044] 1. Prepare materials according to the following types and amounts:

[0045] Weigh 42kg of urea, 25kg of diammonium phosphate, 16kg of potassium sulfate, 1kg of zinc sulfate, 0.18kg of thiophosphoric acid triamide, 0.12kg of dicyandiamide, 12kg of biomass charcoal, 3.2kg of bentonite, and 0.5kg of polyacrylamide polymer .

[0046] 2. The urea, diammonium phosphate, potassium sulfate, zinc sulfate, triamide thiophosphate, dicyandiamide, biomass charcoal, and bentonite weighed in step 1 are mixed uniformly according to the above ratio to obtain a mixture;

[0047] 3. The mixture obtained in step 2 is fed into a disc granulator, and the aqueous solution of polyacrylamide high molecular polymer is sprayed at a rate of 5 liters / minute to granulate. The mass ratio of polymer to water is 1:500. The obtained granular fertilizer is dried at 70°C for 30 minutes, cooled with natural ventilation for 2 hours to room temperature, and the fertilizer granules that have passed the 6-mesh sieve...

Embodiment 3

[0049] 1. Prepare materials according to the following types and amounts:

[0050] Weigh 39kg of urea, 28kg of diammonium phosphate, 18kg of potassium sulfate, 1kg of zinc sulfate, 0.18kg of thiophosphoric acid triamide, 0.12kg of dicyandiamide, 9kg of biomass charcoal, 4.3kg of a mixture of attapulgite and bentonite (including attapulgite) The mass ratio of clay to bentonite is 3:5), and 0.4 kg of polyacrylamide polymer.

[0051] 2. The mixture of urea, diammonium phosphate, potassium sulfate, zinc sulfate, thiophosphoric acid triamide, dicyandiamide, biomass charcoal, attapulgite and bentonite weighed in step 1 is uniformly mixed according to the above ratio to obtain a mixture;

[0052] 3. The mixture obtained in step 2 is sent to a disc granulator, and the aqueous solution of polyacrylamide high molecular polymer is sprayed at a rate of 3 liters / minute to granulate. The mass ratio of polymer to water is 1:400. The obtained granular fertilizer is dried at 70°C for 30 minutes, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com