Gas liquid-pumping device

A liquid extractor and gas technology, applied in the field of gas extractors, can solve the problems of energy consumption, impeller wear and high processing cost, and achieve the effects of strong liquid conveying capacity, convenient installation and use, and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

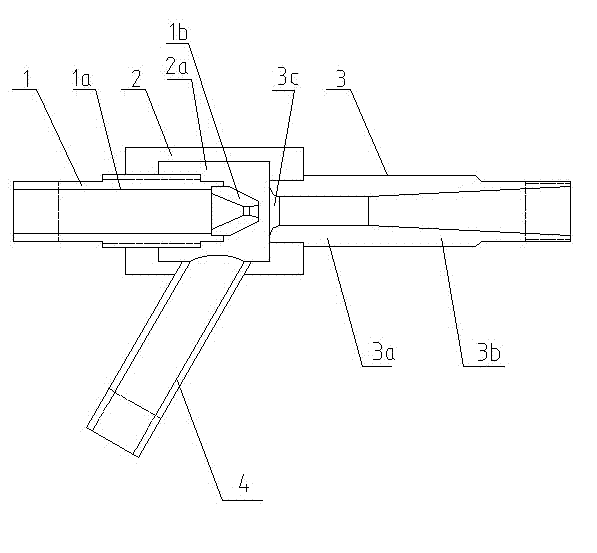

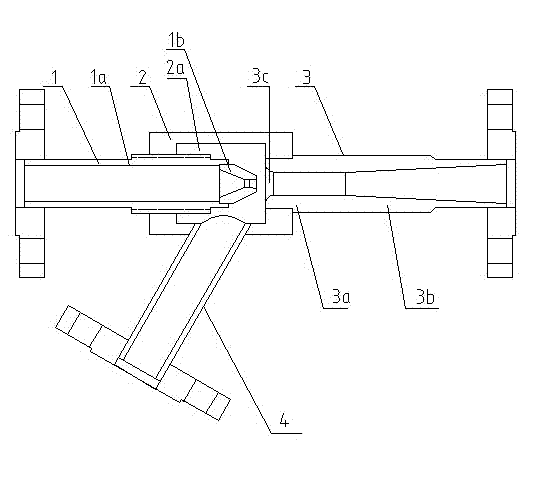

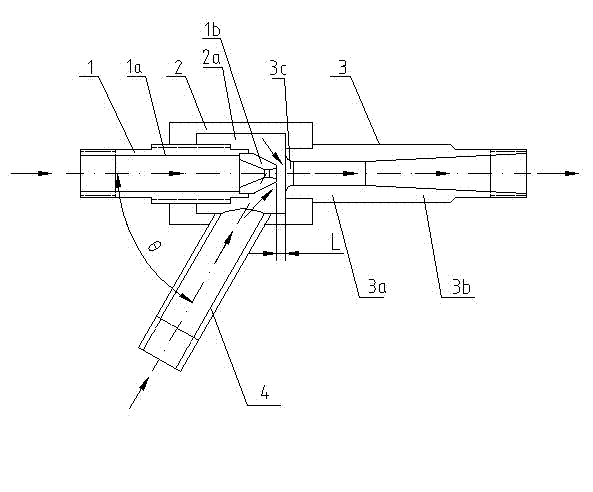

[0027] Such as Figure 1 to Figure 5 As shown, the gas liquid extractor in this embodiment includes a nozzle 1 , a cylinder body 2 , a diffuser tube 3 and a liquid extraction tube 4 .

[0028] The nozzle 1 is composed of a nozzle conduit 1a and a nozzle head 1b. The nozzle conduit 1a is a circular tubular structure. The nozzle conduit 1a is provided with an external thread, and the external thread matches the internal thread on the barrel 2. The inner diameter of the nozzle conduit 1a remains unchanged, reducing the fluid resistance passing through the nozzle conduit 1a. The nozzle head 1b is connected to the nozzle guide 1a. Such as figure 1 As shown, the nozzle head 1b is provided with a nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com