High-coercivity Nd-Fe-B rare-earth permanent magnet and fabrication process thereof

A rare earth permanent magnet and preparation process technology, applied in the manufacture of permanent magnets, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of difficulty in industrialization, low magnetization, affecting the microstructure of magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

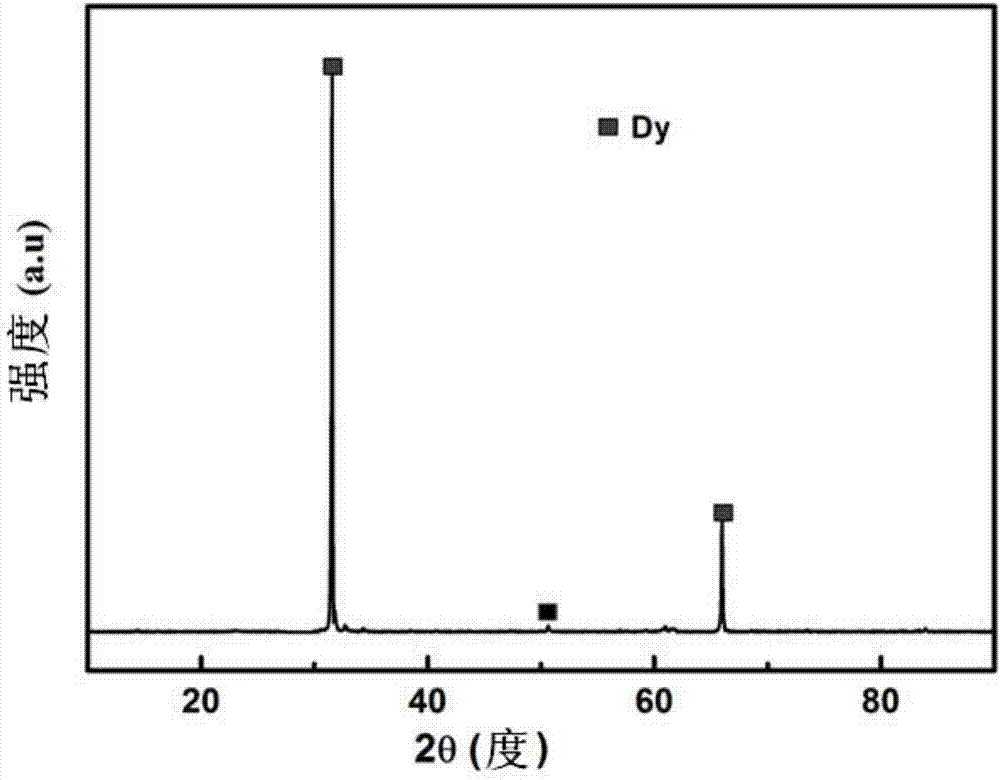

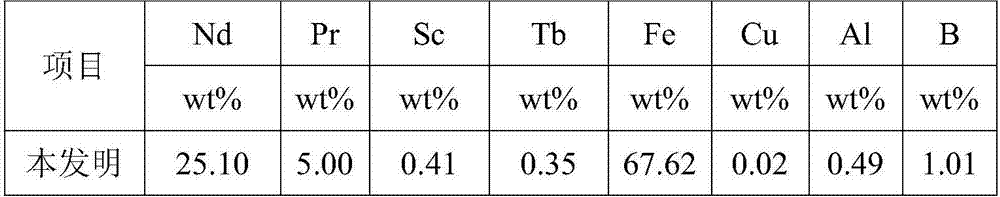

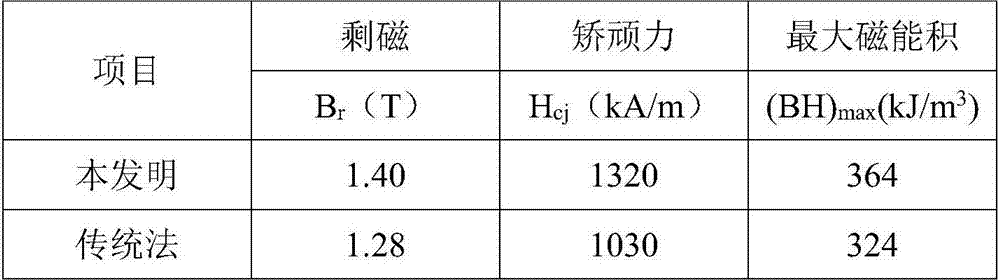

Embodiment 1

[0057] The preparation method of this embodiment is: the invention is to prepare R by the steps of alloy melting, powder making, molding and sintering a FeMB magnets, processed into 10×10×7 (7 is c-axis direction, unit mm) magnets by wire cutting, R b Plated onto the magnet surface by the present invention, wherein the specific parameters adopted by the electrodeposition method (preparation of rare earth film by ionic liquid) are: the ionic liquid is: 1-ethyl-3-methylimidazolium tetrafluoroborate, the main salt TbCl 3 The concentration is 0.2mol / L, the electrodeposition temperature is 20°C, and the current density at constant potential is 6000A m -2 , after coating for 2000s, stop the coating, the film thickness is 3.0μm, and then carry out two-stage heat treatment on the sample, the first-stage heat treatment process is 800°C, keep warm for 1h and then cool, the cooling rate is 50°C / h, and the second-stage heat treatment process is 400°C Keep warm at ℃ for 1 hour, and the co...

Embodiment 2

[0063] The preparation method of this embodiment is: the invention is to prepare R by the steps of alloy melting, powder making, molding and sintering a FeMB magnets, processed by wire cutting into 10×10×8 (8 is the c-axis direction, unit mm) magnets, R b Plated onto the magnet surface by the present invention, wherein the specific parameters adopted by the electrodeposition method (preparation of rare earth film by ionic liquid) are: the ionic liquid is: 1-ethyl-3-methylimidazolium tetrafluoroborate, the main salt TbCl 3 The concentration is 0.2mol / L, the electrodeposition temperature is 70°C, and the current density at constant potential is 6000A m -2 , after coating for 2000s, stop the coating, the film thickness is 3.0μm, and then carry out two-stage heat treatment on the sample, in which the first-stage heat treatment process is 800°C, keep warm for 100h and then cool, the cooling rate is 300°C / h, and the second-stage heat treatment process is 655 Keep warm at ℃ for 10 h...

Embodiment 3

[0069] The preparation method of this embodiment is: the invention is to prepare R by the steps of alloy melting, powder making, molding and sintering a FeMB magnets, processed by wire cutting into 10×10×1 (1 is c-axis direction, unit mm) magnets, R b Plated onto the magnet surface by the present invention, wherein the specific parameters adopted by the electrodeposition method (preparation of rare earth film by ionic liquid) are: the ionic liquid is: 1-butyl-1-methylpyrrole bistrifluoromethylsulfonimide salt, Main salt TbCl 3 The concentration is 0.2mol / L, the electrodeposition temperature is 40°C, and the current density at constant potential is 3000A m -2 , after coating for 1800s, stop the coating, the film thickness is 5.0μm, and then carry out two-stage heat treatment on the sample, in which the first-stage heat treatment process is 700°C, keep warm for 10h and then cool, the cooling rate is 150°C / h, and the second-stage heat treatment process is 480°C Keep warm at ℃ f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com