Hypochlorous acid production system and high-stability hypochlorous acid production method thereof

A production system and technology of hypochlorous acid, which is applied to cells, electrolysis process, electrolysis components, etc., can solve the problems of insufficient chemical properties of hypochlorous acid, difficult to effectively control the production quality, and difficult to store for a long time, and achieve start-stop And liquid level monitoring, high production efficiency, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

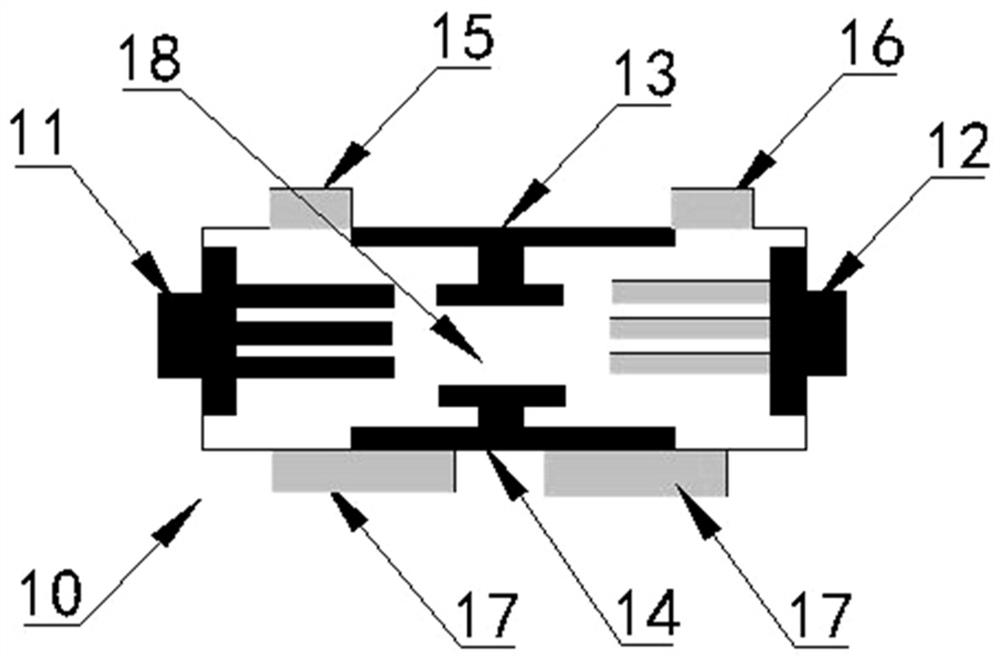

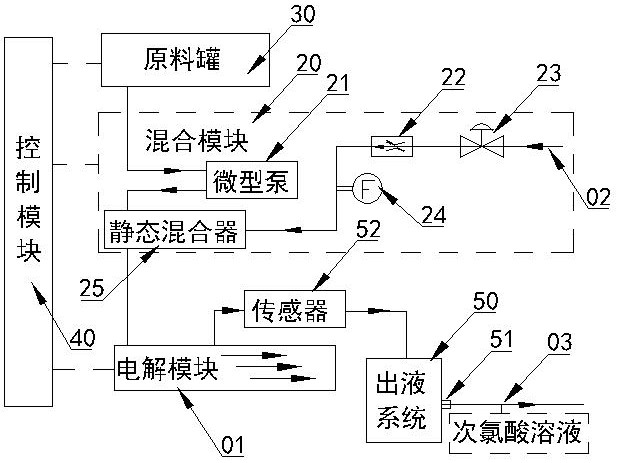

[0029] figure 1 , figure 2 , image 3 In the embodiment shown, a hypochlorous acid production system includes a raw material input device and a liquid outlet system, also includes an electrolysis module and an ultrasonic vibrator, the electrolysis module includes an electrolytic cell 10 and an electrolysis power supply, and the ultrasonic vibrator is installed in the electrolysis In the electrolytic cell 10 of the module, the electrolysis module is used to electrolyze the mixed solution of sodium chloride solution (NaCl) and pure water to generate chlorine gas; the ultrasonic vibrator is used to use ultrasonic vibration to make the chlorine gas generated by the electrolysis module form nano-scale cavitation Bubbles are synthesized and burst again by ultrasonic vibration at the moment when the bubbles burst, and the cavitation bubbles generate local temperature and pressure diffusion at the moment of formation and bursting, and the synthesis of hypochlorous acid solution is c...

Embodiment 2

[0035] figure 1 , figure 2 , image 3 In the embodiment shown, a mixing module 20 is connected between the electrolysis module 01 and the raw material tank 30, and the mixing module 20 is connected to the front stage of the liquid addition input end of the electrolysis module 01. The mixing module 20 includes a micro pump 21, Water inlet control system and static mixer 25; the micro pump 21 includes a micro pump inlet and a micro pump outlet, the micro pump inlet is used to inject sodium chloride (NaCl) solution from the raw material tank 30, and the micro pump outlet Connected to the static mixer 25 (see the direction of the arrow in the figure); the water inlet control system has a water inlet controller 22, the water inlet control system has a water inlet and a water outlet, and the water outlet is connected to the static mixer 21 ; The static mixer 21 comprises a mixer outlet and a mixer inlet, and the mixer inlet is connected with the micro-pump 21 outlet and the water...

Embodiment 3

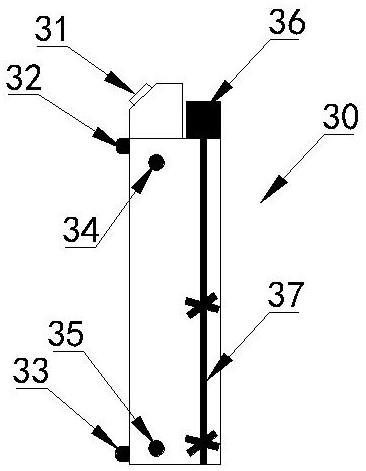

[0038] figure 2 , image 3 In the embodiment shown, the raw material input device adopts a raw material tank. The raw material tank 30 includes a micro vertical brushless motor 36 and a stirring paddle 37. The micro vertical brushless motor 36 is installed on the top of the raw material tank 30 and has a through hole through into the raw material tank 30, and the stirring paddle 37 is connected with the miniature vertical brushless motor through the through hole. The raw material tank 30 includes a tank body, and the tank body is provided with a feed port 31, a discharge port 33 and a liquid level replenishment port 32, and a liquid level detection system is provided inside the tank body. The liquid level detection system is a high liquid level detection sensor 34 and a low liquid level detection sensor 35. The high liquid level detection sensor 34 is installed at a high level inside the tank body; the low liquid level detection sensor 35 is installed in the tank. the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com