Preparation method of neodymium iron boron magnet

A magnet manufacturing method, NdFeB technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of wasting heavy rare earth resources, difficult to control film uniformity, and low magnetization intensity, and achieve control Film thickness and film uniformity, easy film thickness and film uniformity, good effect of film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

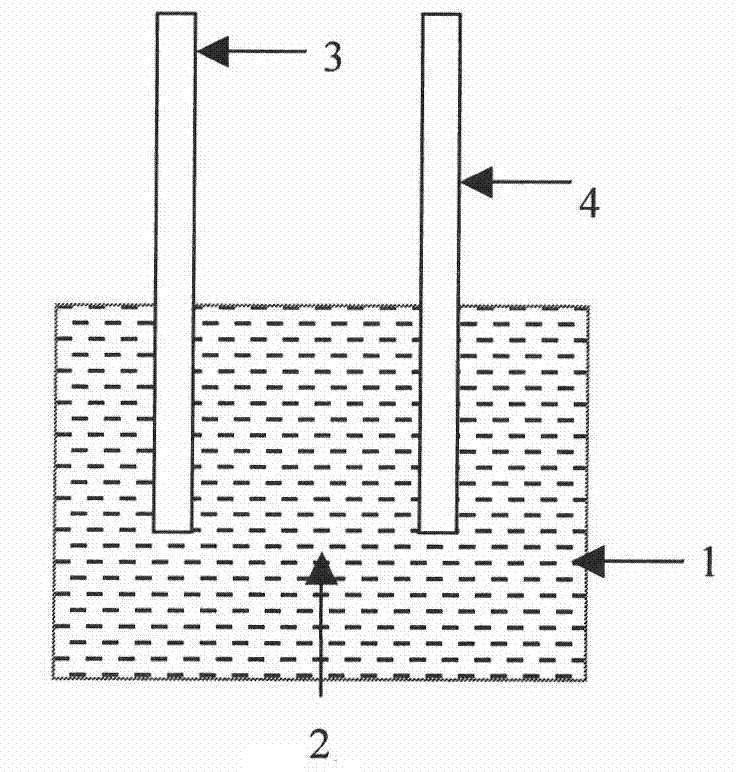

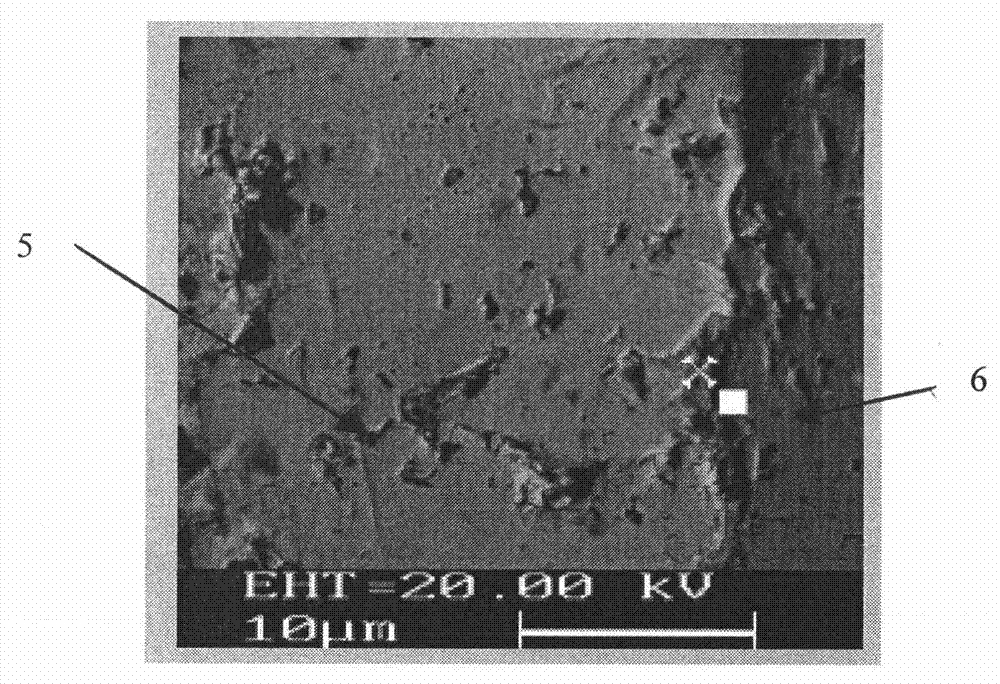

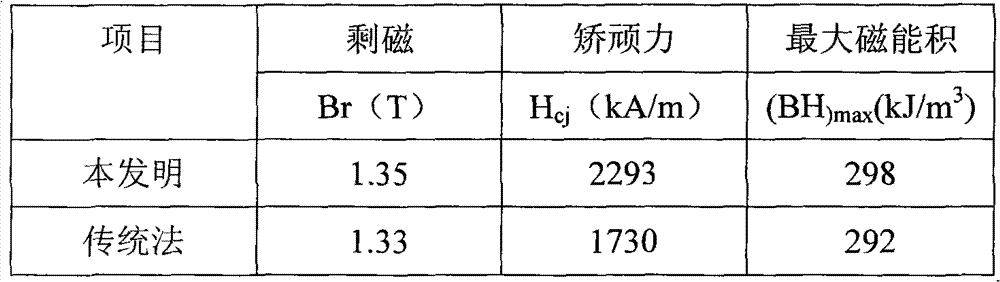

[0040] The preparation method of this embodiment is as follows: processing into 10×10×3mmR 1 FeMB magnet. R 2 Plated onto the magnet surface by the present invention, R 1 FeMB as cathode, R 2 As the anode, the specific parameters used in the electrodeposition method are: the electrolyte is urea 35wt%, NaCl13wt%, KBr is 2wt%, the balance is formamide organic solution, the main salt DyCl 3 The concentration is 0.2mol / L, and the current density at constant potential is 6000A m -2 , after coating for 2000s, stop coating, the film thickness is 3.0 μm, the coating R of the present invention 2 The SEM image of the membrane is shown in figure 2 shown in figure 2 , in the magnet R 1 On the surface of FeMB (also known as matrix) 6, R is plated by electrodeposition 2 Film 5, the heat treatment process is 800 ° C, cooling after 4 hours of heat preservation, the cooling rate is 500 ° C / h, and then 300 ° C for 1 hour, natural cooling at room temperature, the magnetic properties ...

Embodiment 2

[0046] The preparation method of this embodiment is as follows: processing into 10×10×3mmR 1 FeMB magnet. R 2 Plated onto the magnet surface by the present invention, R 1 FeMB as cathode, R 2 As the anode, the specific parameters used in the electrodeposition method are: the electrolyte is urea 33wt%, NaCl13wt%, KBr is 2wt%, the balance is formamide organic solution, the main salt TbCl 3 The concentration is 0.2mol / L, and the current density at constant potential is 6000A m -2 , after coating for 2000s, stop the coating, the film thickness is 3.0μm, the heat treatment process is 800°C, keep warm for 4h and then cool, the cooling rate is 500°C / h, then keep warm at 300°C for 1h, cool naturally at room temperature, and test the magnetic properties of the sample. For comparison, we use the traditional smelting method to add Tb to make magnets. The properties of the magnets are shown in Table 2-1. ICP analysis of the composition of the magnets is shown in Table 2-2. Correspond...

Embodiment 3

[0052] The preparation method of this embodiment is as follows: processing into 10×10×3mmR 1 FeMB magnet. R 2 Plated onto the magnet surface by the present invention, R 1 FeMB as cathode, R 2 As the anode, the specific parameters used in the electrodeposition method are: the electrolyte is 30wt% urea, 12wt% NaCl, 1.5wt% KBr, and the balance is formamide organic solution, the main salt TbF 3 The concentration is 0.2mol / L, and the current density at constant potential is 3000A m -2 After coating for 1800s, stop the coating, the film thickness is 5.0μm, the heat treatment process is 800°C, keep warm for 4h and then cool, the cooling rate is 500°C / h, then keep warm at 300°C for 1h, cool naturally at room temperature, and test the magnetic properties of the sample. For comparison, we use the traditional smelting method to add Tb to make magnets. The properties of the magnets are shown in Table 3-1. ICP analysis of the composition of the magnets is shown in Table 3-2. Correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com