Film forming agent specially used for glass fibers for wind turbine blades, and preparation method thereof

A glass fiber and wind power blade technology, which is applied in the field of a special film-forming agent for glass fiber for wind power blades and its preparation, can solve the problems such as the inability to meet the design and process requirements of 1.5MW-2MW blades, and achieve excellent stable performance and allergic probability. Low, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

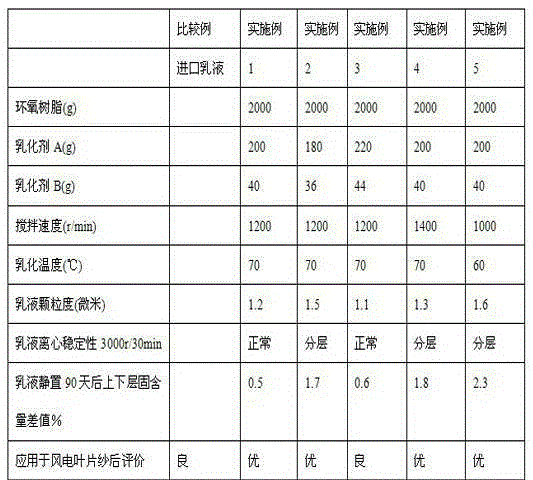

Embodiment 1

[0046] Example 1, bake the epoxy resin to a flow state, put it into the emulsification tank, 2000g, then put in 200g emulsifier A, 40g emulsifier B in turn, adjust the temperature in the emulsification tank to 70°C, and select the stirring speed to 1200r / min , began to add water slowly until it turned into an aqueous phase, and then slowly added water to dilute to a solid content of 55%. Analyze the properties of the samples. And conduct drawing test.

Embodiment 2

[0047] Example 2, add the epoxy resin to the flow state, put it into the emulsification tank, 2000g, then put in 180g of emulsifier A, 36g of emulsifier B in turn, adjust the temperature in the emulsification tank to 70°C, and select the stirring speed to be 1200r / min , began to add water slowly until it turned into an aqueous phase, and then slowly added water to dilute to a solid content of 55%. Analyze the properties of the samples. And conduct drawing test.

Embodiment 3

[0048] Example 3, the epoxy resin is baked to a flow state, put into the emulsification tank, 2000g, and then put in 220g of emulsifier A, 44g of emulsifier B, adjust the temperature in the emulsification tank to 70 ° C, select the stirring speed 1200r / min , began to add water slowly until it turned into an aqueous phase, and then slowly added water to dilute to a solid content of 55%. Analyze the properties of the samples. And conduct drawing test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com