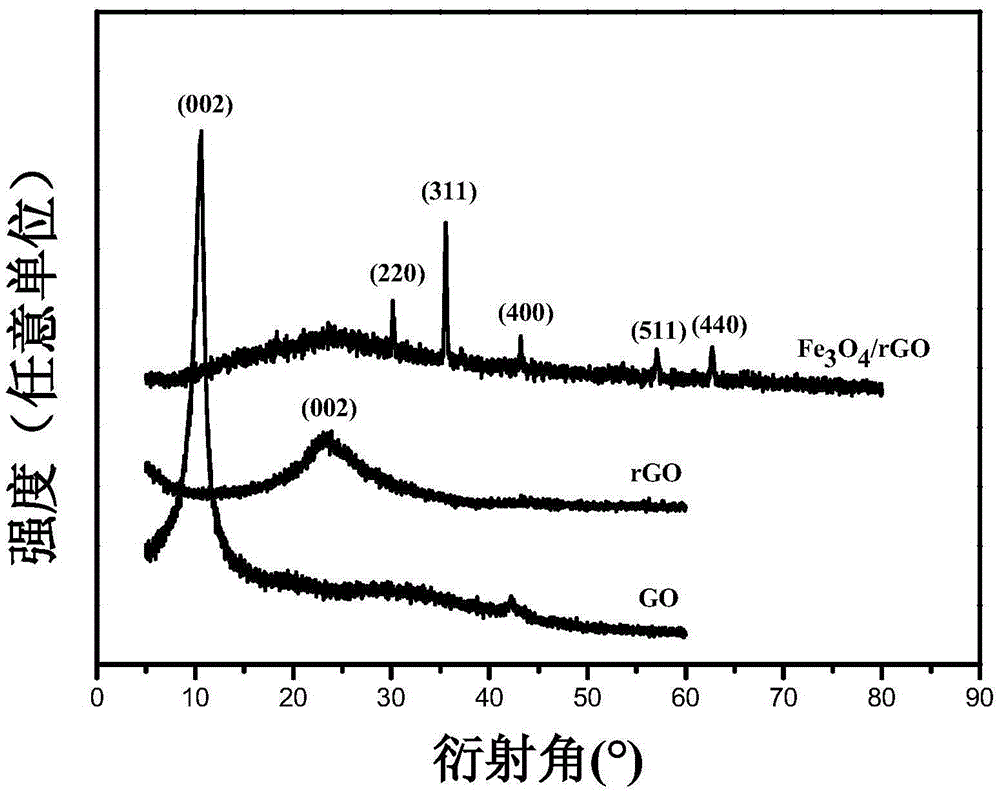

Preparation method of Fe<3>O<4>/graphene composite membrane

A graphene composite, graphene technology, applied in the direction of organic/organometallic film, application of magnetic film to substrate, inductor/transformer/magnet manufacturing, etc., can solve the problem of high-frequency wave absorption effect that needs to be improved and affects the overall component performance, increasing the weight of components, etc., to achieve the effect of low power consumption, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

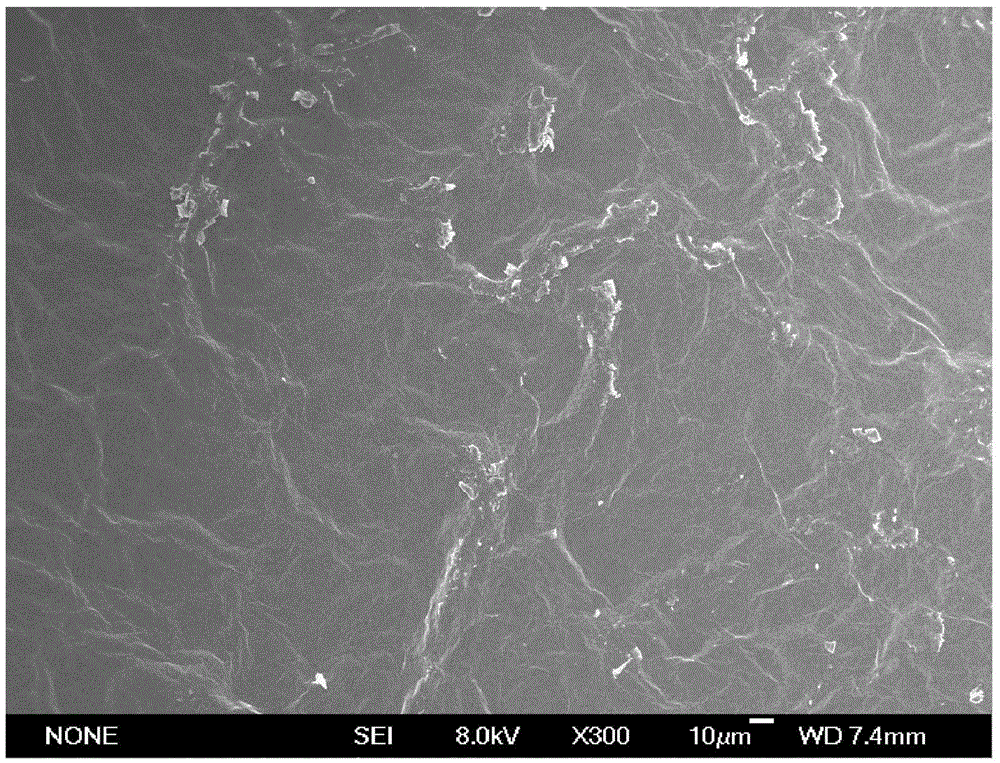

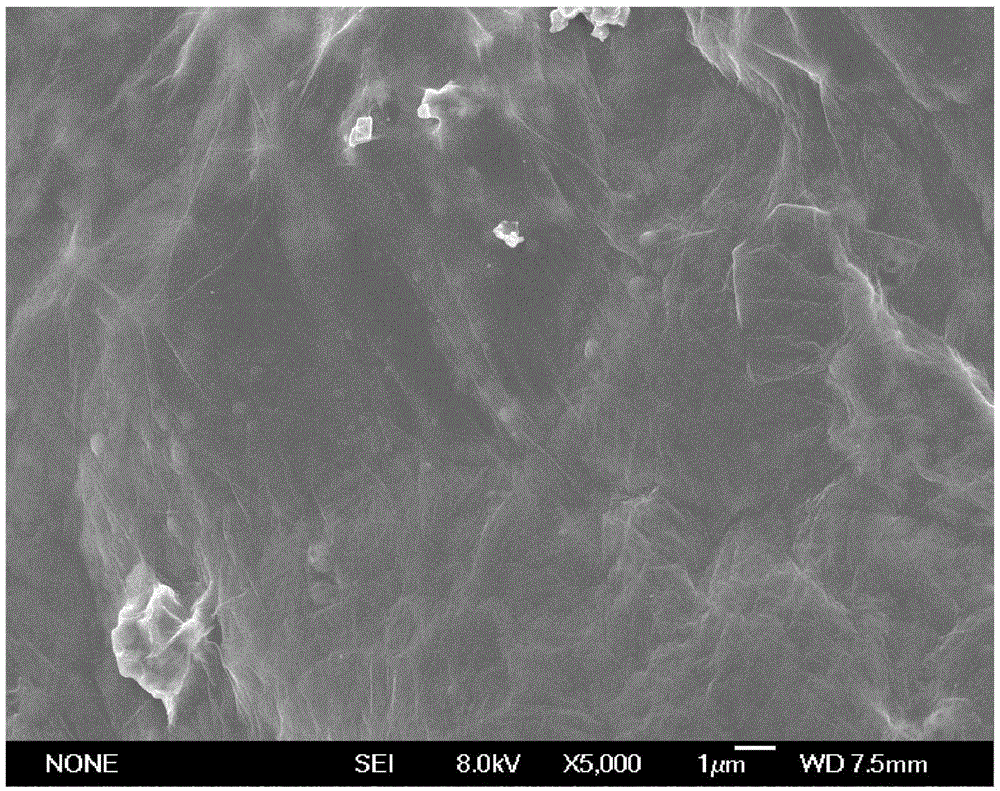

[0032] a kind of Fe 3 o 4 The experimental conditions and parameters of the preparation method of graphene composite film are as follows:

[0033] 1) Put 1.5gNaNO in the Erlenmeyer flask 3 Dissolve in 69ml of concentrated sulfuric acid, add 2g of graphite, stir evenly; add KMnO in an ice-water bath 4 9g, ice-water bath for 12 hours; heat up to 35°C and keep the temperature for 1 hour; then heat up to 60°C and keep the temperature for 18 hours; cool to room temperature, add 200ml ice water to dilute evenly; add hydrogen peroxide drop by drop until the solution has no bubbles and the color turns bright Yellow; after standing for 24 hours, wash and centrifuge with 10% hydrochloric acid for 4 times, then wash and centrifuge with water for 3 times to obtain graphene oxide colloid; take a certain amount of colloid and dry to obtain graphene oxide, calculate the concentration of graphene oxide colloid, the concentration is 19.24mg / ml;

[0034] 2) Add 5ml of citric acid to 95ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com