2.5-dimension (2.5d) multidirectional extensible weaving method

An expansion method and fabric technology, applied in braids, fabrics, textiles, etc., can solve the problems of unable to achieve cross-sectional size expansion, unable to achieve cross-sectional size expansion, unable to achieve 2.5-dimensional structure expansion, etc., to achieve good top fiber continuity, Easy-to-control uniformity, high damage-tolerance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

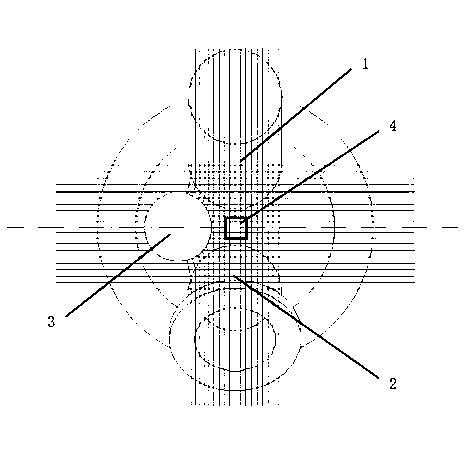

[0022] Example 1: Combining figure 1 The instructions are as follows: set the warp layers of the fabric to 8 layers, and insert the wefts in a clockwise direction column by column.

[0023] figure 1 It is a fabric with a spherical top and three corners. The three corners are regarded as the top of a triangle. The large corner at the top is designated as large corner 1, and the large corner at the bottom is designated as large corner 2. The specific process implementation steps are as follows:

[0024] 1. The fabric adopts 2.5D shallow cross-bending structure.

[0025] 2. During the weaving process, the mandrel is used as the inner core for weaving.

[0026] 3. According to the characteristics of the top, determine the shape of the top as a triangle.

[0027] 4. Adopt the existing roofing technology to complete the roof weaving on the top of the center.

[0028] 5. Finish the roof weaving on the top of the center (such as figure 1 After middle 1), expand the center top wit...

Embodiment 2

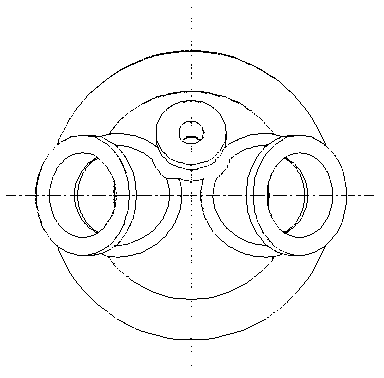

[0042] Example 2: Combining image 3 The instructions are as follows: Set the number of warp layers of the fabric to 6 layers:

[0043] 1. The fabric adopts 2.5D shallow cross-bending structure.

[0044] 2. During the weaving process, the mandrel is used as the inner core for weaving.

[0045] 3. According to the characteristics of the top, determine the shape of the top as a pentagon.

[0046] 4. Use the existing roofing technology to complete the roofing weaving of the central square top (5 in Figure 4).

[0047] 5. After finishing the roof knitting of the center square top, complete the roof knitting of the triangular area with the existing weft insertion technology (6 in Figure 4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com