Method for manufacturing nonvolatile memory device, nonvolatile memory element, and nonvolatile memory device

A technology of non-volatile storage and manufacturing methods, applied in the field of non-volatile storage elements, capable of solving problems such as the easy deterioration of variable resistance elements, and achieving the effects of simplification of the manufacturing process, ease of control, and improvement of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

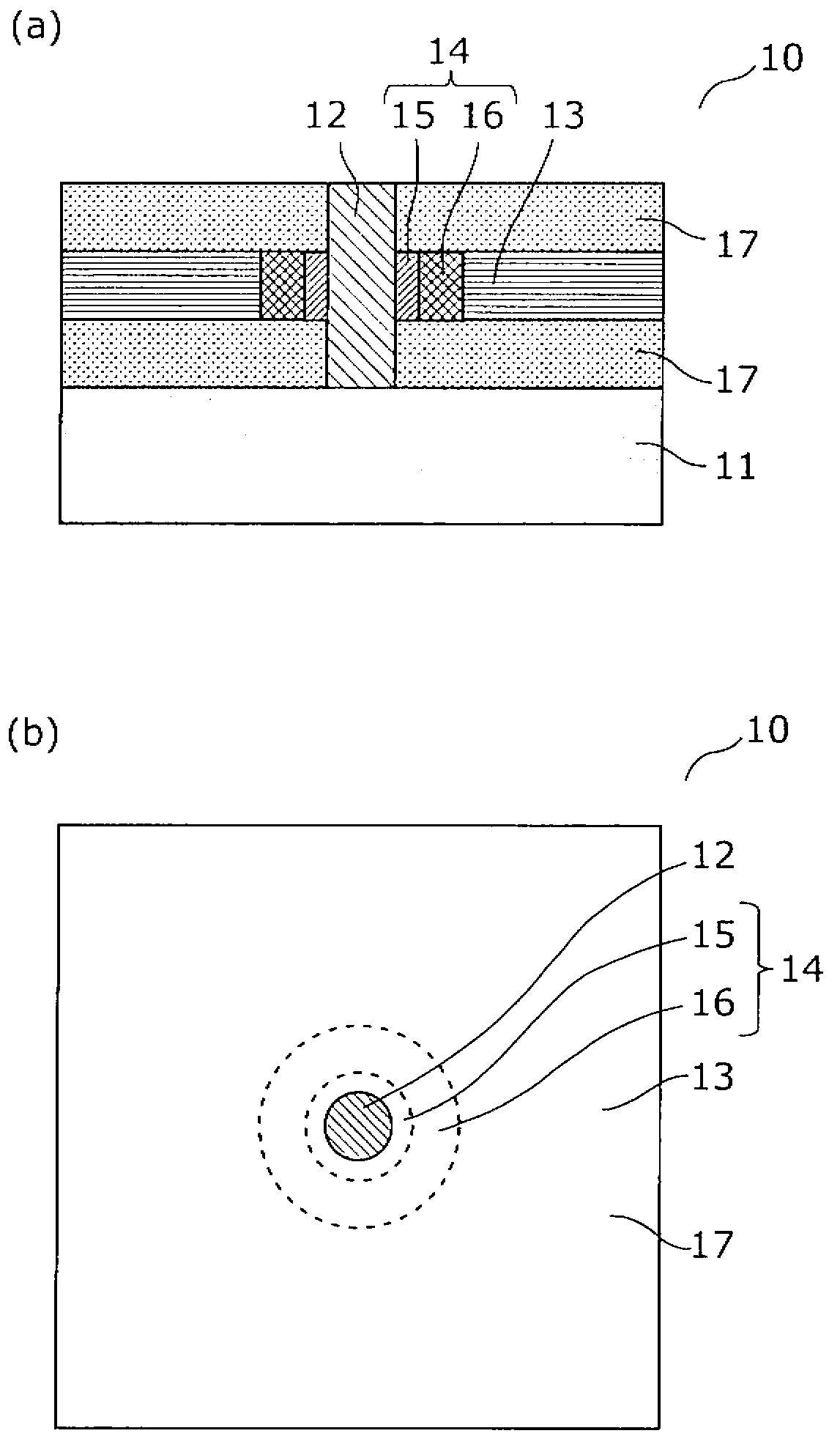

[0054] exist figure 1 represents the nonvolatile memory element according to Embodiment 1 of the present invention. figure 1 (a) is a sectional view of the nonvolatile memory element 10, figure 1 (b) is a plan view of the nonvolatile memory element 10 viewed from above (observed from a direction perpendicular to the substrate 11 ).

[0055] figure 1 The illustrated nonvolatile memory element 10 is composed of a substrate 11 , columnar electrodes 12 , a conductive layer 13 , a variable resistance layer 14 , and an interlayer insulating film 17 . The variable resistance layer 14 is composed of a first variable resistance layer 15 and a second variable resistance layer 16 .

[0056] Conductive layer 13 is formed parallel to the main surface of substrate 11 . The conductive layer 13 and a pair of interlayer insulating films 17 formed in contact with both surfaces (the upper surface and the lower surface) constitute a laminated body. The columnar electrode 12 is a columnar...

Embodiment approach 2

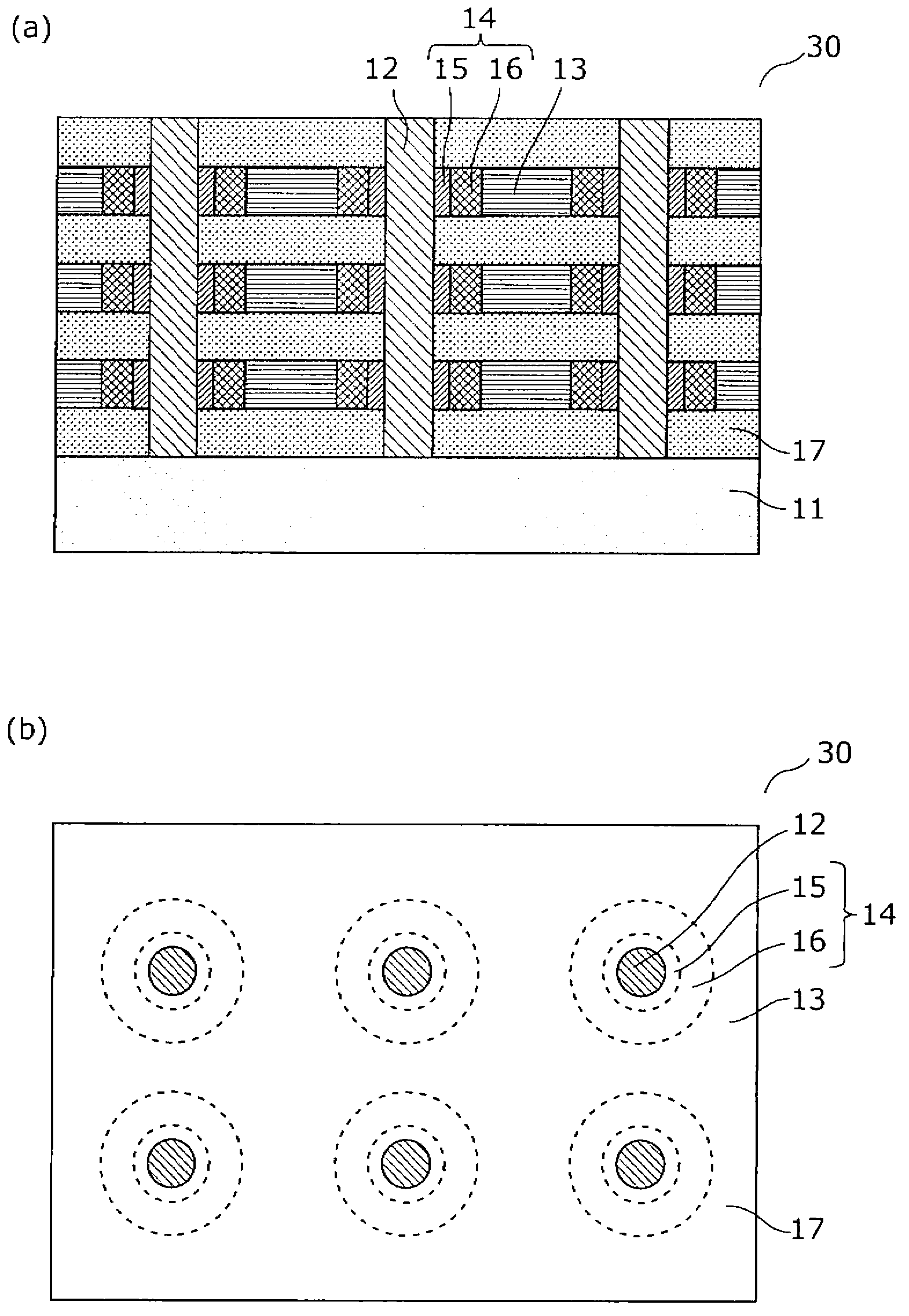

[0075] exist image 3 2 shows the nonvolatile memory device 30 according to Embodiment 2 of the present invention. image 3 (a) is a sectional view of the nonvolatile memory device 30, image 3 (b) is a plan view of the nonvolatile memory device 30 viewed from above (observed from a direction perpendicular to the substrate 11 ).

[0076] Such as image 3 (a), image 3 As shown in (b), the nonvolatile memory device 30 is formed by stacking three layers with 6 memory cells in each layer in the vertical direction (direction perpendicular to the substrate), and 18 memory cells as a whole. memory array in a 3-dimensional configuration. Here, the memory cell corresponds to the nonvolatile memory element 10 of Embodiment 1, and is composed of a columnar electrode 12 , a conductive layer 13 , a variable resistance layer 14 , and an interlayer insulating film 17 .

[0077] Also in the nonvolatile memory device 30, as in the first embodiment, after the contact hole is formed, the p...

Embodiment approach 3

[0082] Figure 5 A nonvolatile memory device 50 according to Embodiment 3 of the present invention is shown. The nonvolatile memory device 50 of Embodiment 3 is a modified example of the nonvolatile memory device 30 of Embodiment 2. As shown in FIG. Figure 5 (a) is a sectional view of the nonvolatile memory device 50, Figure 5 (b) is a plan view viewed from above (observed from a direction perpendicular to the substrate 11 ). Also in this third embodiment, as in the second embodiment, the process can be simplified, and the uniformity of the film thickness of the variable resistance layer 14 can be controlled.

[0083] The difference from Embodiment 2 is that, as Figure 5 (a), Figure 5 As shown in (b), the strip-shaped insulating layer 57 perpendicular to the main surface of the substrate 11 is formed in a columnar shape two-dimensionally arranged in the row direction and the column direction in a plane parallel to the main surface of the substrate 11 . The electrodes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com