Method and device for preparing uniform spherical particles

A technology of spherical particles and granules, which is applied in the field of preparing uniform spherical particles, can solve the problems of inconvenient balling of solid raw materials and uneven balling of liquid raw materials, and achieve controllable particle uniformity, high sphericity, and convenient balling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

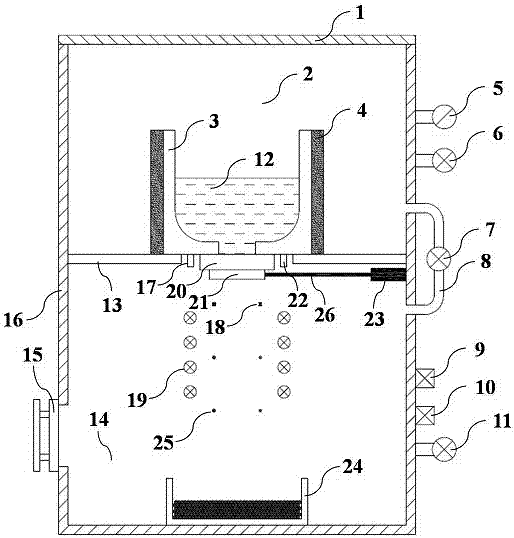

[0015] Example: Preparation of nickel-based superalloy spherical powder.

[0016] Open the vent valve (11), open the door (15), place the collector (24) directly under the water-cooled copper crucible (3), close the door (15), open the upper cover (1), and put the crushed Put the nickel-based superalloy raw material into the water-cooled copper crucible (3), close the upper lid (1), and close the vent valve (11); use the mechanical pump (9) to pump the interior of the warehouse to a low vacuum of 1Pa, and then use The diffusion pump (10) pumps the chamber to a high vacuum of 0.001Pa, turns off the mechanical pump (9) and the diffusion pump (10), and injects high-purity argon into the upper chamber (2) and the lower chamber through the inlet valve (6) (14), so that the air pressure of the upper chamber (2) and the lower chamber (14) is balanced at 0.1MPa, and the ventilation valve (8) on the ventilation pipe (7) is closed; the water inlet pipe (17) and the water outlet pipe (22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com