Compressor impeller and pinion shaft connecting structure and machining method thereof

A compressor impeller and pinion shaft technology, applied in the field of compressors, can solve the problems of difficult installation, low assembly precision, rotor damage, etc., and achieve the effects of easy inspection and maintenance, simple assembly process, and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

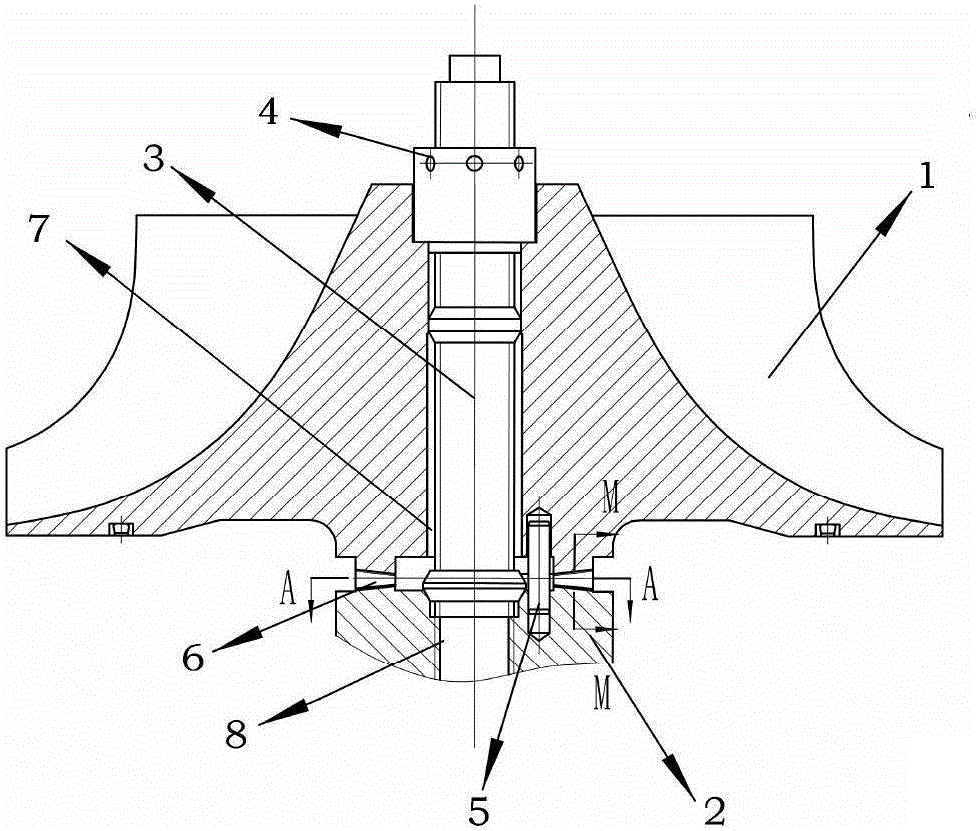

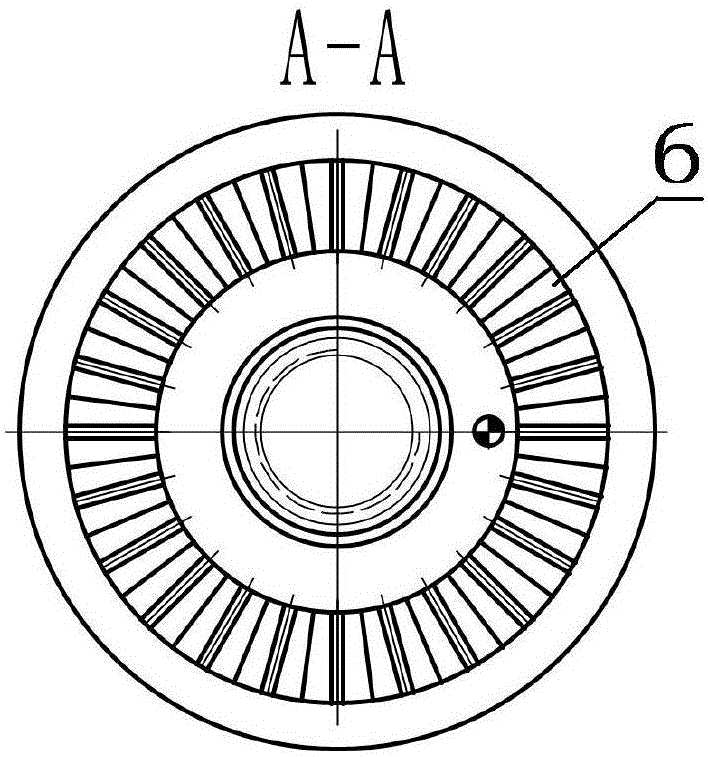

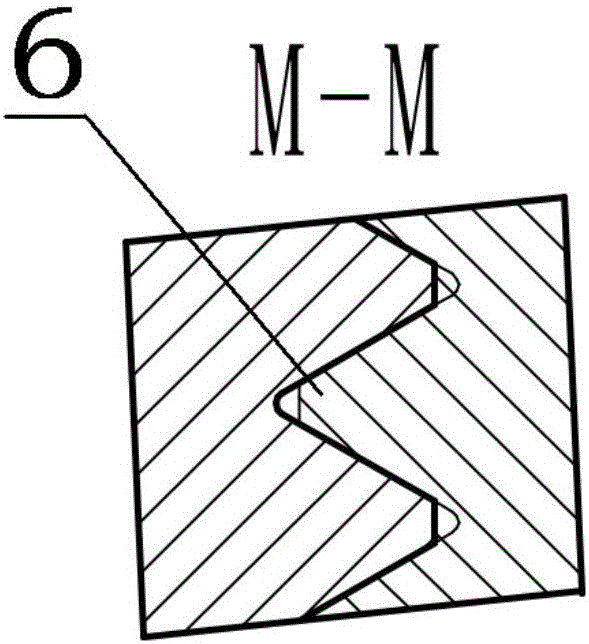

[0031] see figure 1 , A compressor impeller and pinion shaft connection structure provided by an embodiment of the present invention includes an impeller 1 and a pinion shaft 2 cooperating with the impeller 1 . Among them, the tail end of the impeller 1 disc and the end face of the pinion shaft head are provided with end teeth 6 that cooperate with each other, a through hole 7 is provided at the center line of the impeller 1, a threaded hole 8 is provided at the center line of the pinion shaft 2, and the tension bolt 3 The impeller 1 is connected with the pinion shaft 2 through the through hole 7 and screwed in the threaded hole 8 .

[0032] In order to start the positioning function when the impeller 1 and the pinion shaft 2 are connected, the tail end of the impeller 1 disc is provided with a first positioning pin hole, and the end face of the pinion shaft 2 shaft head is provided with a second positioning pin hole corresponding to the position of the first positioning pin h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com