Grating ruler

A technology of grating scale and grating line, which is applied in the field of grating scale, can solve the problem that the repeatability error cannot meet the processing requirements, and achieve the effect of improving precision and eliminating repeatability error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

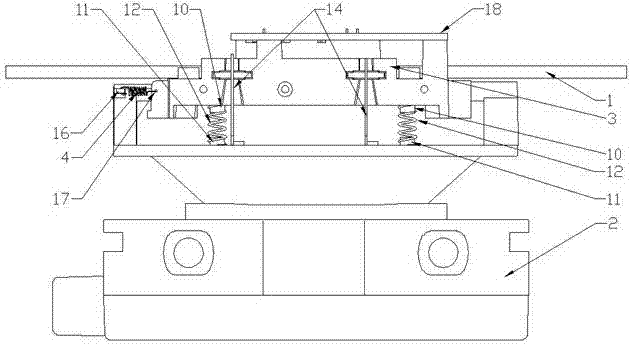

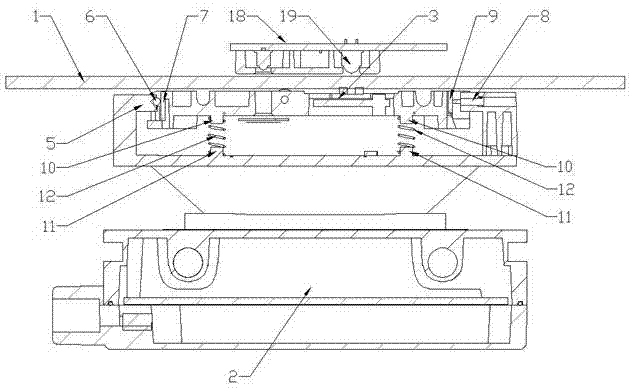

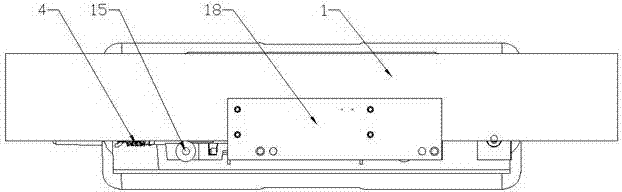

[0024] Such as Figure 1 to Figure 6 As shown, the present invention includes a reading head device and a ruler body device. A glass grating ruler 1 engraved with grating lines is arranged in the ruler body device. The ruler body device is an aluminum profile. 1 Fix on the ruler body device by glue bonding. The ruler body device has holes and is fixed on the bed of the machine tool by screws. The reading head device is fixed to the moving worktable shaft by screws. When the worktable shaft of the machine tool moves, the reading head device of the grating ruler scans the glass grating lines in the ruler device to generate photoelectric signals, which are processed by the signal processing unit. Get the position information of the grating ruler. The reading head device includes a reading head support 2 and a trolley scanning device 3, and the trolley scanning device 3 is fitted on the ruler body device and can move back and forth along the ruler body device. The reading head s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com